When Should You Use 405 nm UV LED Curing?

Deciding on the correct ultraviolet frequency for your manufacturing line requires a precise understanding of how light energy interacts with your specific resins. While many industrial applications favor shorter wavelengths, there are distinct scenarios where a longer frequency is necessary to achieve the desired result. This guide explores the technical applications of 405 nm UV LED curing and how it influences surface quality and material health. By evaluating these factors, you can determine if this near-visible wavelength is the right fit for your specialized assembly or coating process.

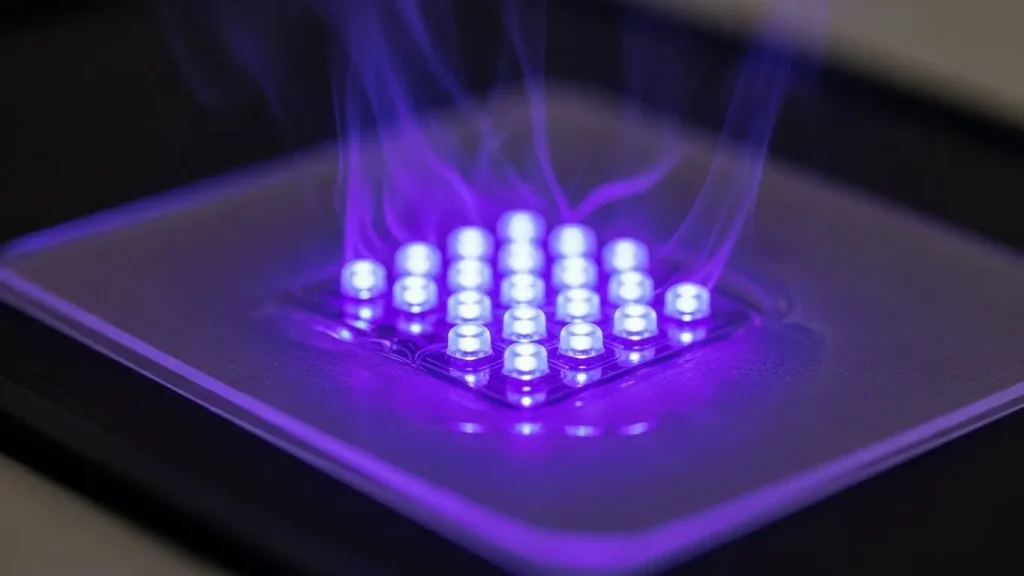

What Is 405 nm UV LED Curing and Why Is It Used?

405 nm UV LED curing refers to a specific UV LED wavelength with relatively lower energy and good surface-cure behavior for many common materials. You will find that this wavelength sits at the very edge of the ultraviolet spectrum, bordering on visible violet light. It is used primarily because it offers a gentler curing process that reduces the risk of yellowing or degrading sensitive substrates. For many manufacturers, it provides a stable way to cure specialized coatings that do not require the intense, high-energy "hit" of shorter wavelengths.

What Materials and Photoinitiators Are Best Suited to 405 nm Curing?

405 nm UV LED curing works well with materials whose photoinitiators absorb and activate efficiently in the 400–420 nm range. You should look for chemistries that utilize TPO-L or other specialized photoinitiators designed for long-wavelength activation. These materials are engineered to capture the energy from the 405 nm peak and convert it into a solid bond quickly.

- Specific Resins: 3D printing resins and dental composites frequently rely on this range for high-resolution results.

- Highly Translucent Glues: Clear adhesives used in optical bonding benefit from the clarity provided by this wavelength.

- Medical-Grade Adhesives: Many plastics used in medical tools are sensitive to shorter UV waves but respond safely to 405 nm.

- Low-Yellowing Coatings: Clear coats that must remain perfectly transparent over time often favor this gentler frequency.

What Practical Production Uses Are Well Suited to 405 nm Curing?

405 nm UV LED curing is often chosen in production for surface coatings, thin films, adhesives, and materials that respond reliably to longer-wavelength UV energy. You will find it used extensively in the assembly of consumer electronics, where it provides a safe way to bond display glass to frames without damaging the underlying sensors. It is also a staple in high-precision additive manufacturing (3D printing), where the wavelength allows for fine detail and consistent layer adhesion.

In the optical industry, you use 405 nm to bond lenses and filters where maintaining the highest possible light transmission is vital. Because the light is closer to the visible spectrum, it often presents fewer safety challenges regarding shielding compared to much shorter UVC rays. This makes it a practical choice for manual workstations where operators need to see the assembly process clearly while the light is active.

How Does 405 nm Compare With Other Common UV LED Wavelengths?

405 nm tends to provide shallower penetration and gentler energy than shorter wavelengths, making it suitable for applications favoring surface cure over depth. When you compare it to 365 nm, you will notice that the 405 nm source is much less likely to cause heat-related warping in thin films. While 395 nm is the "workhorse" for many industrial inks, 405 nm offers a more specialized focus for materials that are extremely sensitive to solarization or color shifts.

What Production and Material Trade-Offs Exist With 405 nm Using?

Using 405 nm involves trade-offs, such as shallower penetration versus gentler thermal exposure. You get the benefit of a "cooler" process that protects your parts from internal stress, but you may find it difficult to cure through very thick or dark, pigmented layers. If your job requires a deep, structural bond through a dense material, you might need to use 405 nm in a secondary stage after an initial deeper cure with a 385 nm or 395 nm lamp.

How Should You Evaluate Whether 405 nm Is Right for Your Application?

Evaluating 405 nm suitability involves matching photoinitiator absorption, desired cure profile, and production conditions. You must start by identifying the peak sensitivity of your material to ensure it aligns with the 405 nm spectral output. Once the chemistry is verified, you should perform a series of tests to confirm that the final bond meets your requirements for hardness and longevity.

- Audit Your Chemistry: Confirm with your supplier that the resin is tuned for 405 nm activation.

- Check Cure Thickness: Verify that the light can penetrate your specific material depth.

- Monitor Surface Quality: Ensure the part is tack-free and maintains its intended color.

- Test Production Speed: Run samples at your actual line speed to confirm the dosage is sufficient.

- Verify Substrate Safety: Confirm that the long-wave energy does not cause brittleness in your plastic parts.

What Are the Key Takeaways on When to Use 405 nm UV LED Curing?

Successful use of 405 nm curing depends on matching your material's photoinitiators to this specific near-visible frequency. It is a specialized tool that offers distinct advantages for sensitive substrates and high-precision assemblies.

- Ideal for materials tuned to the 400–420 nm absorption range.

- Reduces the risk of yellowing or heat damage on delicate parts.

- Best for surface finishes, optical bonding, and 3D printing.

- Requires testing to ensure the energy penetrates deep enough for your specific application.

How Does 405 nm Fit Into the Broader UV LED Spectrum?

To see where this frequency sits in the industrial landscape, you can explore our guide on UV LED curing wavelengths. This explains the differences between UVA and near-visible light and how they affect your manufacturing choices.

How Does Photoinitiator Matching Affect 405 nm Curing Performance?

The chemistry of your resin must be perfectly aligned with your light source to avoid production failures. You can learn more about photoinitiator matching for UV LED to ensure your 405 nm lamp is working at peak efficiency with your materials.

How Does Wavelength Influence Cure Depth and Uniformity?

Understanding the physics of light penetration can help you avoid sticky spots on your parts. Check our technical breakdown of UV LED wavelength and cure depth to see why 405 nm behaves differently than shorter wavelengths.

What Criteria Should You Use When Choosing a UV LED Wavelength?

Selecting the right frequency requires a structured approach to evaluation. Use our checklist to choose a UV LED wavelength based on your materials, production speed, and quality standards.

What Should You Know About 395 nm UV LED Curing Lamps?

As a common industrial alternative, 395 nm offers different energy characteristics than 405 nm. Look at the details of the 395 nm UV LED curing lamp to see if it might be a better fit for your thicker or more opaque coatings.

What Should You Know About 385 nm UV LED Curing Lights?

For applications requiring a balance between surface and depth, 385 nm is a frequent choice. You can find more information about the 385 nm UV LED curing light and how it provides a more versatile energy profile for general assembly.

What Should You Know About 365 nm UV LED Curing Lights?

If your process needs high energy for clear adhesives or legacy chemistry, 365 nm remains a powerful tool. Explore the 365 nm UV LED curing light to see how it provides a more intense surface cure than the 405 nm range.

Final Thoughts

Selecting 405 nm is a strategic decision that prioritizes material health and precision over raw curing power. As manufacturing moves toward increasingly sensitive and complex materials, the ability of this wavelength to provide a gentle, targeted cure makes it a vital tool in the modern production toolkit. By focusing on the technical alignment between your light source and your photoinitiator chemistry, you can build a process that is both highly efficient and remarkably stable. Your goal is to eliminate the guesswork and rely on the specific properties of 405 nm to drive your production quality.