What UV LED Curing Lamp Is Best for Inkjet Printing? (2026 Guide)

The best UV LED curing lamp for your inkjet system is not simply the one with the highest power; it is the one that precisely matches your ink’s photoinitiator sensitivity (typically 395nm) and fits your printer’s speed and form factor. For high-speed single-pass printing, water-cooled systems with high peak irradiance are essential, whereas wide-format scanning printers often perform best with compact air-cooled units.

In this guide, we will help you determine the exact specifications needed for your production line. We will cover:

- Wavelength Selection: Why 395nm is the standard and when you need 365nm.

- Cooling Systems: Deciding between air-cooled and water-cooled architectures.

- Pinning vs. Curing: How to use a dual-lamp strategy for sharper images.

- Power Requirements: Balancing peak irradiance (W/cm²) with energy density (J/cm²).

- Troubleshooting: Fixing common issues like tacky surfaces and poor adhesion.

1. Wavelength Compatibility: The First Check

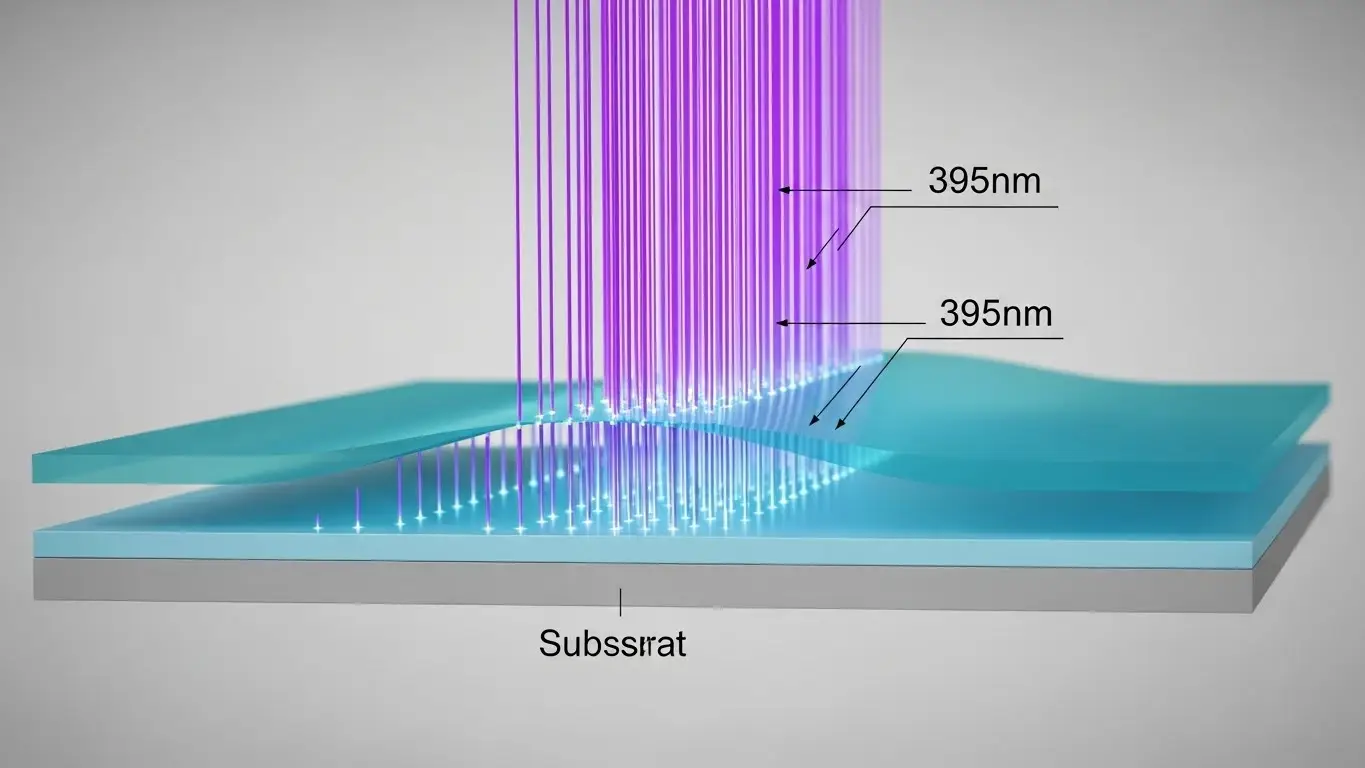

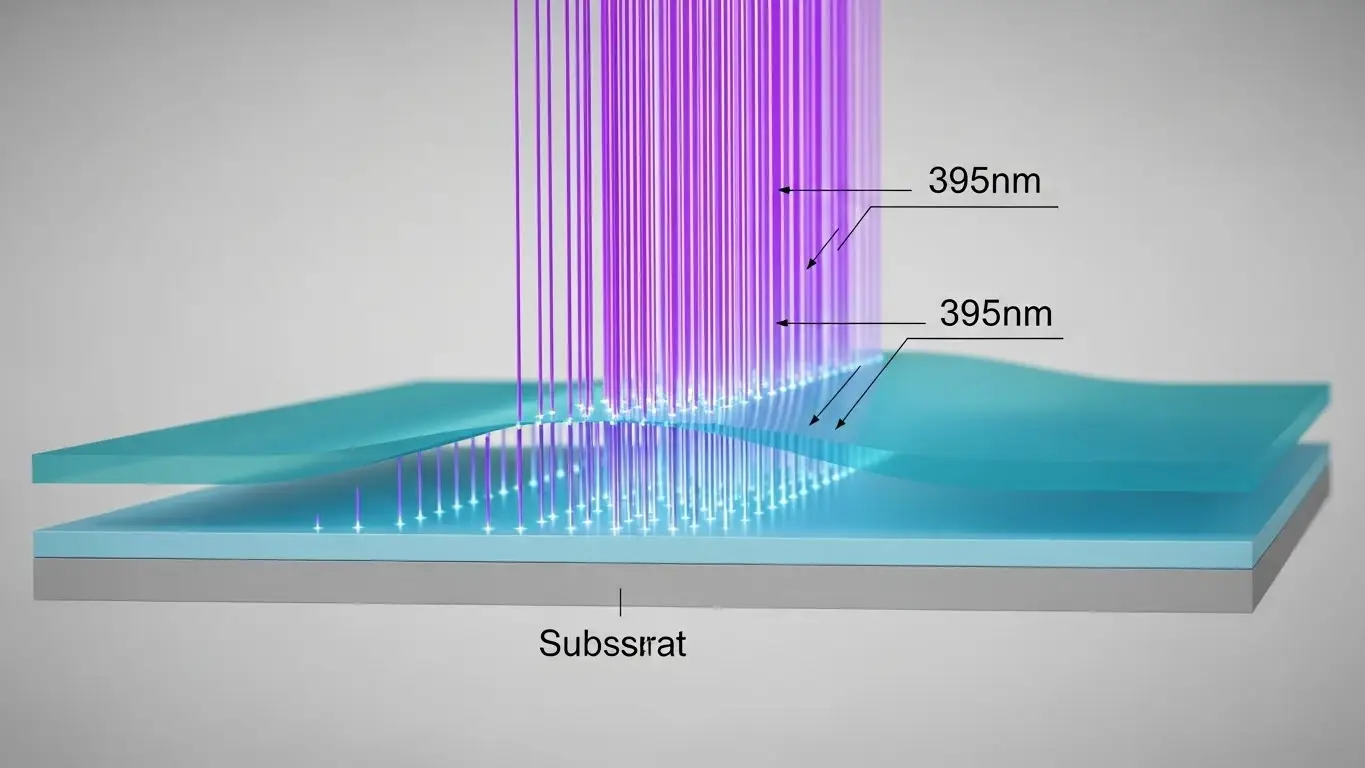

Before looking at power or price, you must look at your ink. The most critical factor in selecting a lamp is matching the LED’s spectral output to the absorption peak of the photoinitiators in your UV ink.

Why 395nm is the Inkjet Standard

For the vast majority of digital inkjet applications, 395nm is the industry standard. This wavelength penetrates deeply into the ink layer, ensuring good through-cure and adhesion to the substrate. It is particularly effective for thicker ink layers and darker colors (like Black and Blue) which can block UV light from reaching the bottom of the print.

When to Use 365nm or 385nm

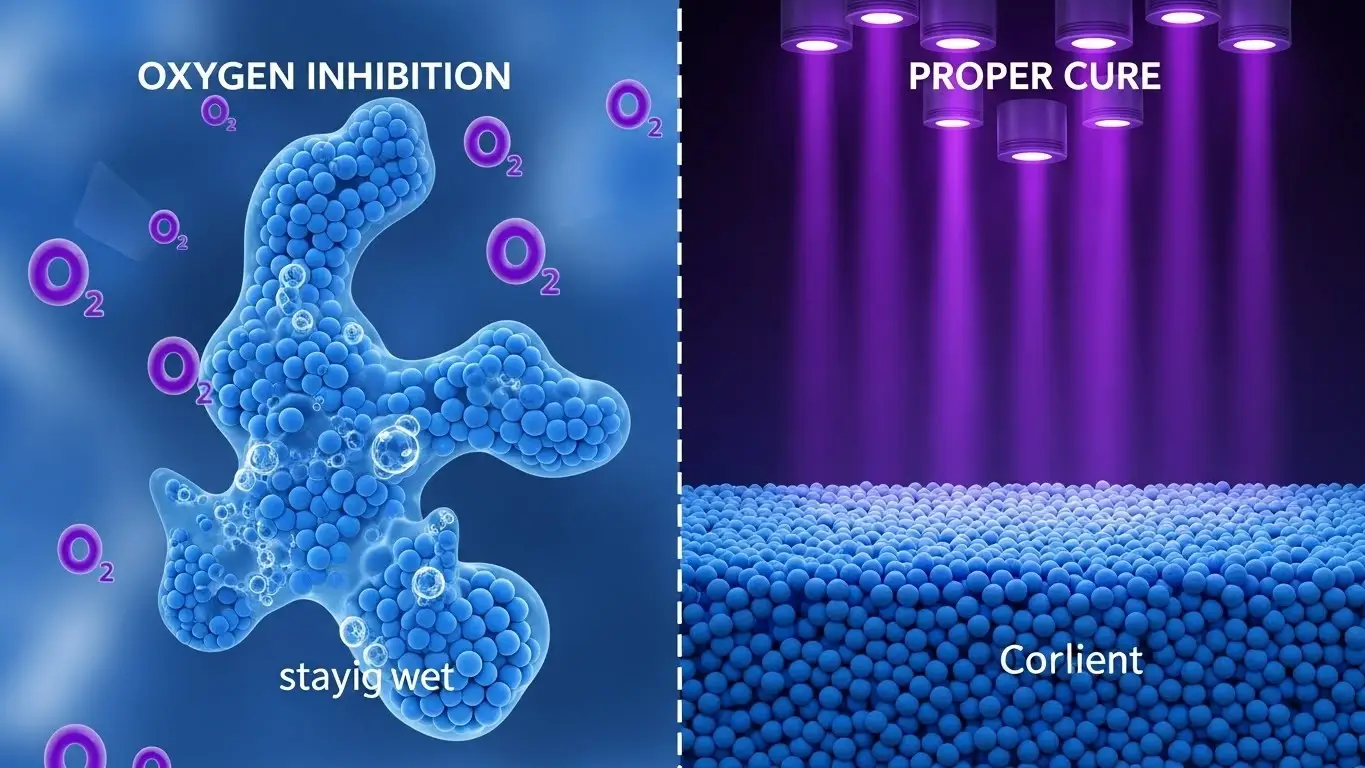

While 395nm is excellent for deep curing, it can sometimes leave the surface slightly tacky because it is susceptible to oxygen inhibition.

- 365nm / 385nm: These shorter wavelengths have higher energy and are better at curing the very top surface of the ink. They are often required for clear varnishes, white inks, or specific industrial coatings where a hard, scratch-resistant surface is immediate priority.

Pro Tip: If you are experiencing surface tackiness with a 395nm lamp, verify if your ink formulation is optimized for LED. You can read more about matching light sources to chemistry in our UV LED ink curing guide.

2. Irradiance vs. Energy Density (Speed Matters)

A common mistake is confusing "brightness" with curing power. In UV LED specs, you need to distinguish between Peak Irradiance (measured in W/cm²) and Energy Density/Dose (measured in J/cm²).

High Speed = High Irradiance

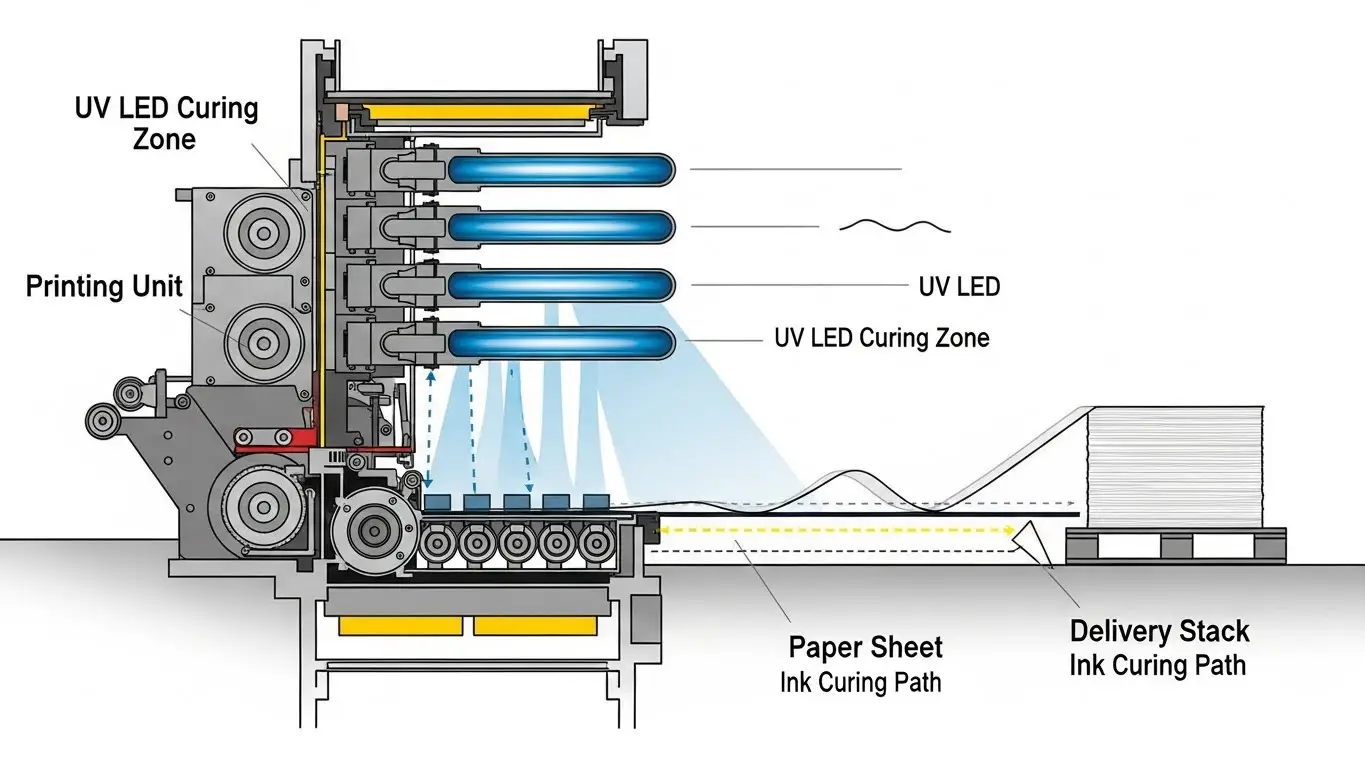

For single-pass inkjet printers (where the substrate moves past a stationary printhead at high speeds, often 50–100m/min), you have only a fraction of a second to cure the ink.

- You need high Peak Irradiance (typically 12W/cm² to 20W/cm² or higher).

- This intense "punch" of light triggers the polymerization instantly before the ink can flow or bleed.

Scanning Systems = High Dose

For wide-format scanning printers (where the carriage moves back and forth), the lamp passes over the ink multiple times.

- Here, extreme peak irradiance is less critical.

- The cumulative Dose (total energy over time) ensures the cure. A lamp with 4W/cm² to 8W/cm² is often sufficient because it exposes the ink repeatedly.

To understand the mechanics of how these photons interact with the ink droplets at different velocities, see our article on how UV LED curing works in inkjet printing.

3. Cooling Systems: Air-Cooled vs. Water-Cooled

The choice between air and water cooling usually comes down to your printer’s architecture and production environment.

| Feature | Air-Cooled UV LED | Water-Cooled UV LED |

| Best Application | Scanning / Wide Format / Plotters | Single-Pass / High-Speed Label / Industrial |

| Size | Larger (needs fans/heatsinks on head) | Compact (slim lamp head, fits tight spaces) |

| Installation | Simple (plug and play) | Complex (requires external chiller) |

| Noise Level | Higher (fan noise) | Silent (at the print head) |

| Maintenance | Clean air filters regularly | Maintain chiller fluid levels |

Common Mistake: Installing an air-cooled lamp in a dirty industrial environment without proper filtration. Dust can clog the fans, causing the LEDs to overheat and lose intensity. For harsh environments, water-cooled systems are often safer as they are sealed units.

4. The "Pinning" Strategy: Why You Might Need Two Lamps

In high-quality inkjet printing, one lamp is often not enough. To achieve sharp text and vibrant images, you need to manage "dot gain" (the tendency of a liquid droplet to spread out on the substrate).

What is Pinning?

Pinning involves using a small, low-power UV LED lamp positioned immediately after the printheads. It delivers just enough energy to "freeze" the ink droplet in place, increasing its viscosity without fully curing it.

The Two-Step Process

- Pinning: A low-intensity lamp (often 395nm or 405nm) freezes the dot size. This prevents colors from bleeding into each other and keeps text sharp.

- Full Cure: A high-power lamp at the end of the process delivers the final dose to fully harden the ink and ensure adhesion.

If you are seeing blurry edges or "mottled" colors, you likely need to integrate a pinning solution rather than just increasing the power of your main curing lamp.

5. Form Factor & Optics: Fitting the Lamp to the Printer

Inkjet print carriages are crowded real estate. The "best" lamp must physically fit without interfering with the printheads or the media path.

- Working Distance: Inkjet heads typically sit 2mm to 10mm from the substrate. UV intensity drops rapidly over distance. The best UV LED lamps use quartz optics to focus the light output specifically at this working distance, ensuring minimal energy loss.

- Stray Light: Lamps must be designed to prevent UV light from reflecting back up into the printheads. If UV light hits the nozzle plate, it will cure the ink inside the nozzle, ruining the printhead. Quality lamps include shutters or focused optics to prevent this.

6. Troubleshooting Common Inkjet Curing Issues

If you already have a system but are facing quality issues, check these common variables before buying a new lamp.

- Ink is Tacky (Surface Cure Failure):

- Cause: Oxygen inhibition is preventing the top layer from curing.

- Solution: Increase irradiance, switch to a spectrum that includes shorter wavelengths (like a mix of 385/395nm), or use a nitrogen inerting system (rare for standard inkjet).

- Substrate Deformation (Warping):

- Cause: Too much heat transferred to the substrate (common with mercury lamps, but possible with overpowered LEDs).

- Solution: Ensure your LED system has efficient thermal management. You may be running higher irradiance than necessary—try dimming the lamp.

- Poor Adhesion (Scratching Off):

- Cause: Under-curing at the base of the ink layer.

- Solution: The 395nm wavelength might be blocked by heavy pigment density. Increase the total dose (slow down the belt) or check if the lamp intensity has degraded due to dirt on the window.

7. Recommended UV LED Solutions for Inkjet

At UVET, we categorize our solutions based on the printing method to ensure the right fit.

- For Scanning & Wide Format: We recommend our Air-Cooled Series. These offer easy integration for carriage-mounted systems where the lamp moves with the head.

- For High-Speed Single Pass: Our Water-Cooled Series provides the ultra-high irradiance (16W/cm²+) needed to cure instantly at speeds exceeding 50m/min.

- For Pinning Applications: We offer compact Mini-LED Modules designed to fit snugly between printhead clusters for immediate dot freezing.

FAQ: Switching to UV LED for Inkjet

What is the best wavelength for UV inkjet ink?

The standard wavelength is 395nm, as it penetrates thick ink layers well. However, some specific applications (like varnishes or whites) may benefit from 365nm or 385nm for better surface curing.

What is the difference between pinning and full curing?

Pinning uses low power to "freeze" the ink drop to prevent spreading (dot gain), while full curing uses high power to completely harden the ink for durability and adhesion.

Can I retrofit my mercury lamp inkjet printer with UV LED?

Yes, retrofitting is common. You will need to ensure the LED lamp fits physically and that your ink supplier offers an LED-compatible ink formulation (since LEDs output a narrow spectrum compared to mercury).

How much irradiance (W/cm²) do I need?

Scanning printers typically need 4–8 W/cm², while high-speed single-pass printers often require 12–20 W/cm² or more to cure instantly at production speeds.

Do UV LED lamps get hot?

The LEDs themselves generate heat and must be cooled (by air or water), but they emit very little infrared heat toward the substrate compared to mercury lamps, making them safe for heat-sensitive films.

How long do UV LED curing lamps last?

A quality UV LED lamp typically lasts over 20,000 hours of operation, compared to 1,000–2,000 hours for a traditional mercury arc bulb.

What is the cost difference between mercury and LED curing?

LED systems have a higher upfront cost but save significantly on operating costs (up to 70% energy savings), eliminate bulb replacement costs, and reduce downtime, often resulting in an ROI of 12–18 months.

Why is my UV ink not curing on plastic substrates?

This is often due to surface energy issues or "oxygen inhibition." Ensure your substrate is treated (corona treatment) and that your lamp intensity is sufficient to overcome oxygen interference at the surface.

Conclusion

Selecting the best UV LED curing lamp for inkjet printing requires balancing the chemistry of your ink with the mechanics of your machine. Whether you need the raw power of a water-cooled system for single-pass labels or the flexibility of an air-cooled unit for wide-format graphics, the goal is consistent, fully cured output with minimal heat.

If you are unsure which wavelength or irradiance level your specific ink requires, contact UVET’s engineering team today. We can help you run compatibility tests to ensure you invest in the right system for your production line.