Can UV LED Cure Powder Coating?

Yes, UV LED technology can cure powder coating, provided you use specific UV-curable powder formulations. Unlike traditional powder coatings that rely solely on high heat for long periods to crosslink (cure), UV powder coatings separate the melting and curing phases. First, the powder is melted onto the part using low heat (or infrared), and then it is instantly cured by exposure to UV LED light. This separation allows the process to happen much faster and at significantly lower temperatures, making it ideal for heat-sensitive materials like wood, MDF, and assembled components containing plastic or electronics.

How Does UV LED Powder Coating Work?

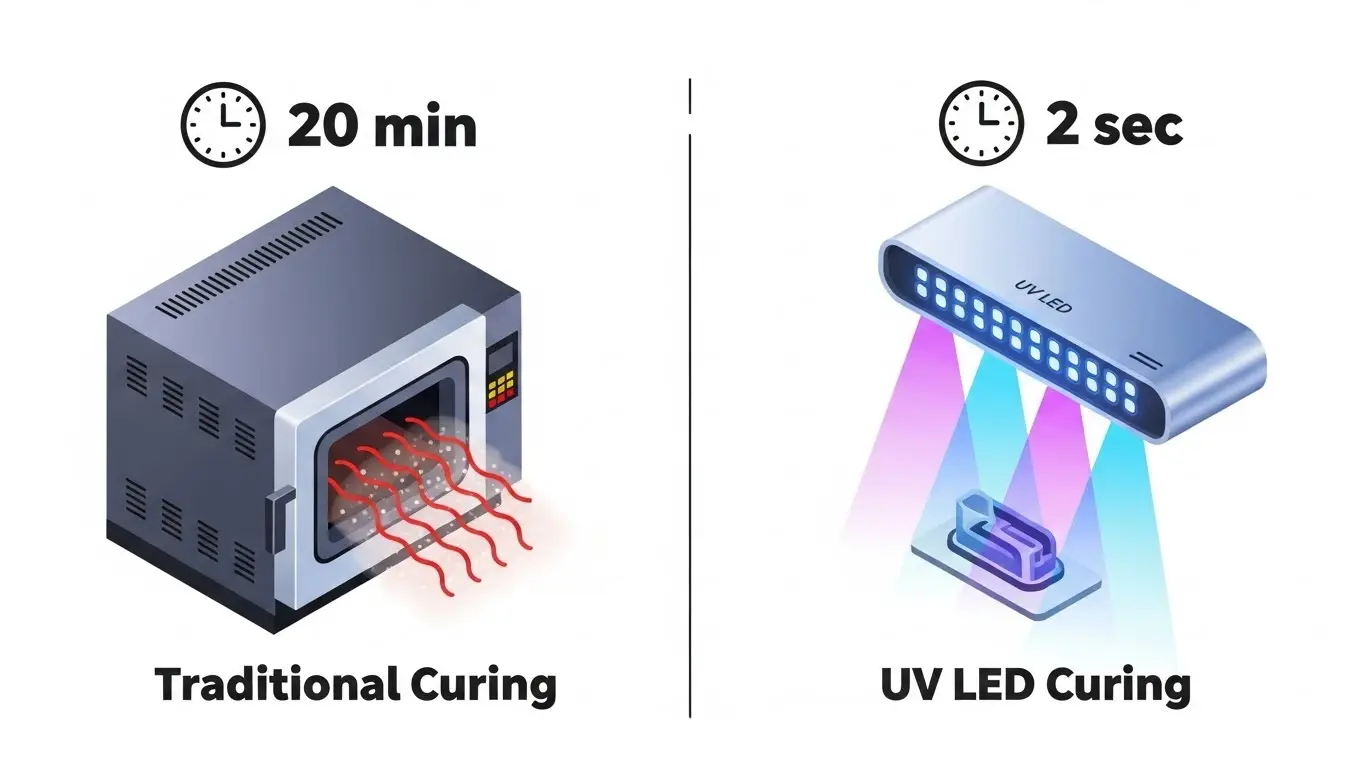

To understand how this technology works, it is important to distinguish it from the traditional thermal process. In standard powder coating, the part must bake in an oven at high temperatures (often around 400°F) for 20 minutes or more to cure.

UV LED curing changes this dynamic by splitting the process into two distinct stages:

- The Melt Stage: The powder is applied electrostatically and then heated just enough to melt the powder into a smooth film. This takes only 1–2 minutes at much lower temperatures (typically 230°F - 265°F).

- The Cure Stage: Once the powder flows out, the part passes under a UV LED lamp. Photoinitiators within the powder absorb the UV energy and instantly crosslink the polymer.

This efficiency is a major reason why industries are adopting UV LED Curing for Coatings. It drastically reduces energy consumption and the physical footprint of the production line.

Key Benefits of UV LED for Powder

- Speed: Curing happens in seconds, not minutes.

- Energy Efficiency: UV LEDs consume less power than traditional mercury arc lamps or large thermal convection ovens.

- Heat Management: Lower operating temperatures protect sensitive substrates.

What is the Difference Between Thermal and UV Powder Coating?

Thermal powder coating relies on heat for both melting and curing, while UV powder coating uses heat only to melt and UV light to cure.

While traditional thermal curing is excellent for metal parts that can withstand high heat, it limits what you can coat. UV LED curing opens the door to new materials. Below is a comparison of how the two methods stack up.

Comparison: Thermal vs. UV LED Powder Coating

| Feature | Thermal Curing (Traditional) | UV LED Curing |

| Cure Mechanism | Heat (Thermal Energy) | UV Light Energy |

| Process Temperature | High (350°F - 400°F+) | Low (230°F - 265°F) |

| Cure Time | 10–30 Minutes | Instant (Seconds) |

| Substrate Suitability | Metals (Steel, Aluminum) | Metals, Wood, MDF, Plastic, Composites |

| Energy Consumption | High | Low |

Can You Use UV Light to Cure Regular Powder Coat?

No, you cannot use UV light to cure standard thermal powder coatings.

Standard powder coatings are formulated to crosslink using thermal energy. If you expose them to UV light, they will not cure; they will simply remain a melted, sticky mess on the surface of your part.

To utilize UV LED technology, you must use powders specifically formulated with photoinitiators. These are chemical compounds that react to specific wavelengths of UV light to trigger the hardening process.

When exploring What Coatings Can Be Cured with UV LED?, it is critical to ensure your material supplier provides "UV-curable" powder. Just as you need specific chemistry for UV LED Curing for UV Varnish, the powder chemistry must match the light source output (typically 365nm, 385nm, or 395nm wavelengths).

Can You Powder Coat Wood and MDF with UV LED?

Yes, UV LED curing is actually the preferred method for powder coating wood and Medium Density Fiberboard (MDF).

Because wood and MDF contain moisture, subjecting them to the high temperatures of a traditional powder coat oven causes outgassing (bubbles in the finish) and can warp or crack the material.

Since UV LED curing requires only enough heat to melt the powder (roughly 230°F for a very short time), the core of the wood stays cool. This prevents damage to the substrate and allows manufacturers to create durable, seamless finishes on office furniture, kitchen cabinetry, and retail displays.

The MDF Process

- Pre-heating: Briefly warm the board to bring moisture to the surface (makes it conductive).

- Application: Spray the powder electrostatically.

- Melting: Run through a low-heat IR zone or convection oven for 1–2 minutes.

- Curing: Pass under UV LED lamps for instant hardening.

Frequently Asked Questions

Is UV powder coating as durable as traditional powder coating?

Yes, UV-cured powder coatings offer durability, scratch resistance, and chemical resistance comparable to high-quality thermal powders. However, as with all coatings, the specific durability depends on the formulation of the powder used.

Does UV LED curing save money?

Generally, yes. While the initial equipment cost can be higher, the operational savings are significant. You save on energy bills (LEDs are efficient and you don't need to keep a massive oven hot all day), and you save on floor space since you don't need long cooling tunnels.

Can I retrofit my existing line for UV LED?

It is possible to retrofit, but it requires modification. You will likely keep your spray booth, but you will need to replace or modify your baking oven to serve only as a "melt oven" and install a UV LED curing station at the end of the line.

Is UV LED curing safe for operators?

UV LED systems are generally safer than older mercury-lamp UV systems because they produce no ozone and contain no mercury. However, operators must still wear protective eyewear and cover skin to prevent direct exposure to UV light.

Key Takeaways

- Requires Special Powder: You must use UV-curable powder formulations; standard thermal powders will not work.

- Ideal for Heat-Sensitive Parts: The low-temperature process allows for coating wood, MDF, and plastics.

- Instant Curing: The curing phase happens in seconds, significantly speeding up production lines.

- Energy Efficient: Separating the melt and cure phases reduces overall energy consumption compared to traditional thermal baking.

Conclusion

Can UV LED cure powder coating? Absolutely. It is not only possible but is rapidly becoming a standard for industries looking to coat heat-sensitive materials or reduce their carbon footprint. By utilizing UV-curable powders and modern LED technology, manufacturers can achieve a durable, high-quality finish in a fraction of the time required by traditional methods.

If you are looking to improve your production efficiency or coat new materials like MDF, exploring UV LED solutions is the next logical step.