LED UV Curing Systems for Printing Machines: What to Compare

Finding the right LED UV curing systems for printing machine upgrades can feel like navigating a maze of technical specs and manufacturer promises. If you are running an offset or flexo press, you know that the wrong choice doesn’t just cost money—it costs downtime, wasted substrate, and lost clients.

I’ve seen pressroom managers struggle with "drop-in" solutions that didn’t account for their specific heat sensitivities or line speeds. The reality is that not all LED arrays are created equal. To get the 20,000+ hour lifespan and instant-on efficiency that LED promises, you need to look beyond the brochure wattage. You need to compare the "invisible" factors: cooling architecture, optical control, and integration logic.

This guide breaks down exactly what to compare so you can choose a system that delivers a consistent cure, shift after shift.

What Are the Key Performance Metrics for LED UV Curing?

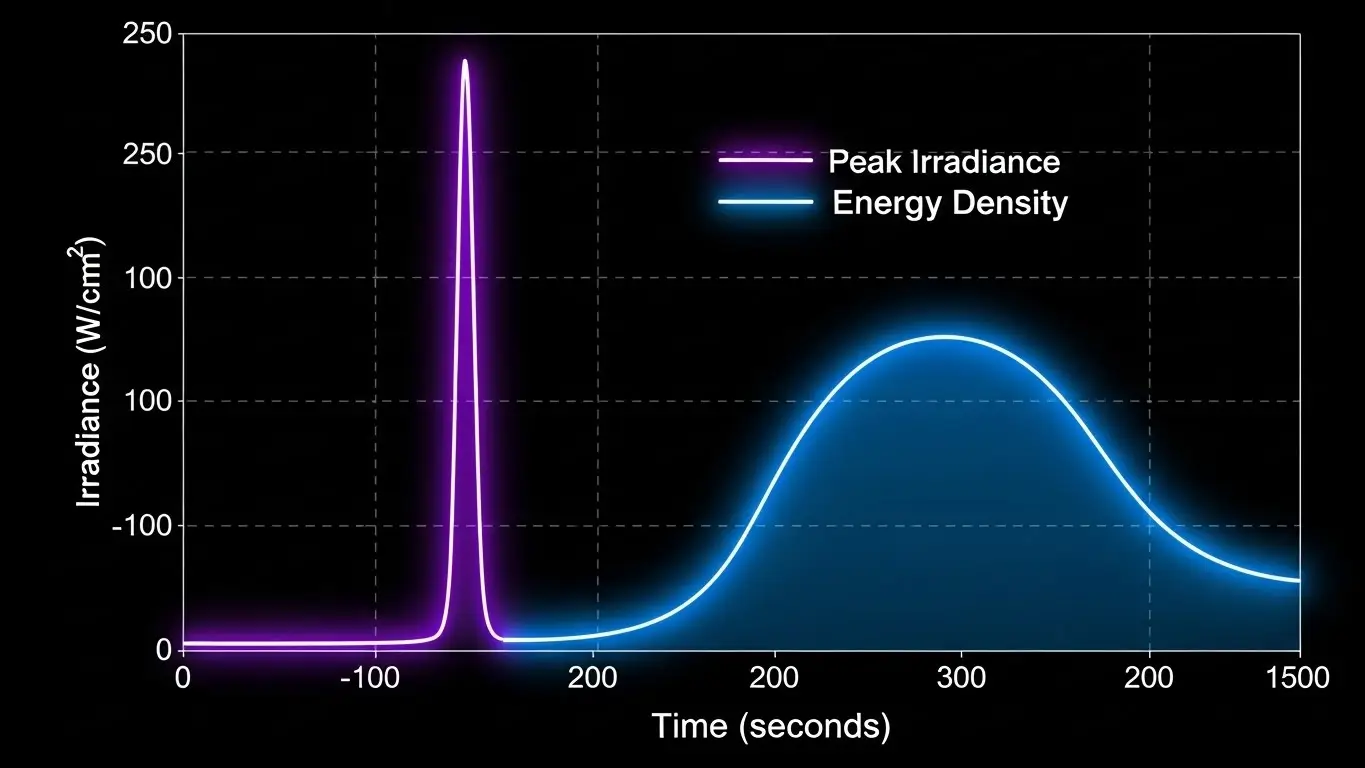

To evaluate performance, look beyond peak irradiance (W/cm²). You must compare the total energy density (J/cm²) delivered to the substrate at your maximum line speed. A high peak intensity is useless if the dwell time is too short to fully polymerize the ink. Always request data on dose uniformity across the entire curing width.

Deep Dive: Irradiance vs. Energy Density

When you are comparing specs, most manufacturers shout about their Peak Irradiance—often citing numbers like 12W/cm² or 16W/cm². While high intensity is necessary to penetrate thick ink layers (especially opaque whites or blacks), it is not the whole story.

For a thorough comparison, you need to focus on Energy Density (measured in Joules/cm²). This is the total amount of UV energy that actually lands on your print surface over time.

- Peak Irradiance: The "punch" of the light (intensity).

- Energy Density: The "punch" multiplied by the time it hits the ink (dose).

If you run a high-speed web press, a system with a narrow emitting window might not deliver enough total energy to cure the ink, even if its peak intensity is high. You need a system with a wider emitting window or higher efficiency optics to maintain cure quality at speed.

| Metric | What It Measures | Why It Matters |

| Peak Irradiance (W/cm²) | Maximum light intensity. | Critical for penetrating thick/pigmented inks. |

| Energy Density (J/cm²) | Total energy delivered. | Determines if ink fully cures at speed. |

| Emitting Window Size | Physical area of light output. | Wider windows allow faster press speeds. |

| Uniformity (+/- %) | Consistency across the width. | Prevents "tacky" edges on wide webs. |

How Does Cooling Technology Affect System Longevity?

Cooling is the single biggest predictor of LED lifespan. Compare the thermal management designs: water-cooled systems are generally superior for high-power, wide-format offset presses as they maintain stable junction temperatures. Air-cooled units are simpler but can suffer from intensity drop-off in hot pressrooms or during long runs.

The "Silent Killer" of LED Arrays

Heat is the enemy of LED efficiency. As LED chips get hotter, their UV output drops, and their lifespan shortens. When we talk about a "20,000-hour lifespan," that is only valid if the LED junction temperature stays within a specific safe zone (usually under 80°C).

What to Compare:

- Water-Cooled Systems:

- Pros: Best for stability. A chiller keeps the LEDs at a precise temperature regardless of the ambient heat in your factory. This is essential for UV LED Curing for Offset Printing where lamps run at high power for hours.

- Cons: Requires plumbing and a chiller unit.

- Air-Cooled Systems:

- Pros: Easier to install; no water lines. Great for narrow web or smaller applications.

- Cons: Performance can fluctuate if your facility gets hot in the summer. Fans can clog with paper dust if not properly filtered.

Pro Tip: Ask manufacturers for their "intensity vs. temperature" degradation curves. If a system loses 20% of its output after 4 hours of running, it’s not built for industrial printing.

Which Integration Features Matter for Offset Presses?

Effective integration requires more than just bolting a lamp to the press. You must compare the control logic: Does the system offer "step-less" dimming linked to press speed? Look for systems with compact form factors that fit between print units (interdeck) and PLC connections that automate on/off cycles to prevent substrate burning during stops.

Seamless Retrofitting

Retrofitting an older press with modern LED UV is a game-changer, but only if the mechanical and electrical integration is smooth. You don’t want a system that requires your operator to manually adjust UV power every time they speed up or slow down the press.

Key Integration Checkpoints:

- Speed-Dependent Power: The system should automatically lower UV intensity when the press slows down and increase it when it speeds up. This prevents overheating the substrate and saves energy.

- Form Factor: Offset presses are crowded. You need ultra-compact lamp heads that can fit in the delivery or interdeck positions without interfering with grippers or transfer cylinders.

- Signal Interface: Ensure the curing system supports standard industrial protocols (like Modbus or simple I/O) to talk to your press’s main computer.

For a deeper look at how to physically fit these systems into tight spaces, check our guide on Offset Printing UV LED Curing System: Integration Options.

How Do I Match Wavelengths to My Ink Formulations?

Wavelength matching is non-negotiable for cure adhesion. Most standard LED UV inks cure best at 395nm, but some specialty applications require 385nm or 365nm for surface cure or specific varnishes. Compare the available wavelength configurations and ensure your ink supplier certifies compatibility with the specific nanometer output of the lamp.

The Nanometer Niche

Unlike old mercury lamps that blasted a broad spectrum of light (producing ozone and wasted heat), LEDs emit a narrow band of UV light. This precision is great for efficiency but requires strict compatibility.

- 395nm: The industry workhorse. It penetrates well and cures most standard LED UV offset inks.

- 385nm: Often used for higher-performance curing where slightly less depth but more surface reactivity is needed.

- 365nm: Closer to the "traditional" UV spectrum. Expensive, but necessary for certain adhesives or special coatings that don't react to longer wavelengths.

- 405nm: sometimes used for specific thick-layer additives or 3D printing, less common in standard offset.

If you are unsure which specific ink series you will be running, or if you run a mix of jobs, you need to consult your consumables provider. You can read more about this in our resource on What Inks Are Compatible with LED UV Offset Curing?.

Why Is Irradiance Uniformity Critical for Quality?

Non-uniform curing leads to "tacky" strips in the print or uneven gloss levels. Compare the optical design of the LED arrays—specifically, look for systems that use micro-lens technology or advanced reflectors to ensure the UV energy is distributed evenly across the entire web width, rather than having "hot spots" in the center and weak edges.

Avoiding the "Zebra Stripe" Effect

I’ve diagnosed print failures where the center of the sheet was bone dry, but the edges smeared in the stack. This usually happens because the LED array has gaps between modules or poor optical lensing.

What to Look For:

- Buttable Modules: If the manufacturer builds wide arrays by stacking smaller modules, ensure they are "seamlessly stackable" with no dead zones between them.

- Edge Control: Good systems allow you to turn off outer LED zones if you are printing on a narrower sheet. This saves energy and prevents curing ink on the impression cylinder.

- Optics: Does the system use a flat glass window (flood) or a focused lens? Focused lenses can deliver more energy to the substrate, which is crucial for Sheetfed Offset LED UV Curing: Typical Applications.

For practical advice on getting this right on the press floor, review our Sheetfed LED UV Curing Setup Tips for Consistent Cure.

What ROI Factors Should I Calculate Before Buying?

True ROI comes from energy savings, maintenance reduction, and uptime. Compare the "Total Cost of Ownership" (TCO) rather than just the sticker price. LED systems typically cut energy bills by 50-70% compared to mercury lamps and eliminate the $500+ annual cost per bulb replacement, often paying for themselves in 12-24 months.

The Math Behind the Switch

When pitching this investment to stakeholders, you need hard numbers. Here is what to calculate:

- Energy Consumption:

- Mercury: 100% power during standby (shuttered).

- LED: 0% power during standby (instant off).

- Result: Massive drop in kWh usage.

- Consumables:

- Mercury: Bulbs fade every 1,000-2,000 hours. Reflectors degrade.

- LED: Lasts 20,000+ hours. No reflectors to replace.

- Make-Ready Time:

- LEDs are instant-on. No 10-minute warm-up cycles waiting for lamps to strike.

- Scrap Rate:

- Consistent curing means less waste from offsetting or blocking in the pile.

| Cost Factor | Traditional UV | LED UV |

| Bulb Replacement (Yearly) | $2,000+ (approx. 4 changes) | $0 |

| Standby Energy Cost | High (Lamps stay on) | $0 (Instant Off) |

| Heat Damage Waste | Common (warped substrates) | Rare (Cool cure) |

| Ozone Extraction | Required (Ducting/Fans) | Not Required |

If you are ready to crunch the numbers for your specific facility, check out our dedicated guide on How to Choose LED UV Curing for Offset Printing.

Conclusion

Choosing the right LED UV curing systems for printing machine applications isn't just about picking the brightest light. It is about matching the energy density to your speed, ensuring the cooling system can handle your environment, and integrating the controls seamlessly into your workflow.

By focusing on these core comparison points—Energy Density vs. Irradiance, Cooling Architecture, Wavelength Compatibility, and Optical Uniformity—you can secure a system that improves your print quality and lowers your operating costs for the next decade.

Ready to upgrade your press?

Don't guess at the specs. Verify your specific requirements. Whether you need a retrofit for a vintage Heidelberg or a new setup for a high-speed flexo line, prioritize stability and integration above all else.

- PREV: Sheetfed Offset LED UV Curing: Typical Applications

- NEXT: Null