How to Reduce Odor in UV Flexo Inks with LED Curing

Learning how to avoid odor in UV flexo inks with LED curing is critical for converters targeting sensitive markets like food and pharmaceutical packaging.

In the competitive world of flexographic printing, brand owners are increasingly intolerant of "off-gassing" or chemical smells on their labels. I’ve been on press floors where a fresh roll of labels smelled like a chemistry set—a guaranteed rejection from any food safety auditor. The shift to LED technology isn't just about energy savings; it is the most effective strategy for mitigating these sensory risks. By controlling polymerization and eliminating ozone, you can achieve a neutral-smelling, high-compliance product.

Below is a comprehensive guide to mastering odorless production using LED UV technology.

What Causes Odor in UV Flexo Inks?

The primary causes of odor in UV flexo inks are unreacted monomers trapped in the ink film, photolytic byproducts from photoinitiators, and ozone generation from conventional mercury lamps. Additionally, excessive heat can cause substrates to release their own plasticizers, contributing to the overall "taint" or smell of the final printed product.

The Chemistry of the Smell

To solve the problem, we first have to understand the enemy. In my experience troubleshooting quality issues, the "smell" rarely comes from just one source. It is a compound effect.

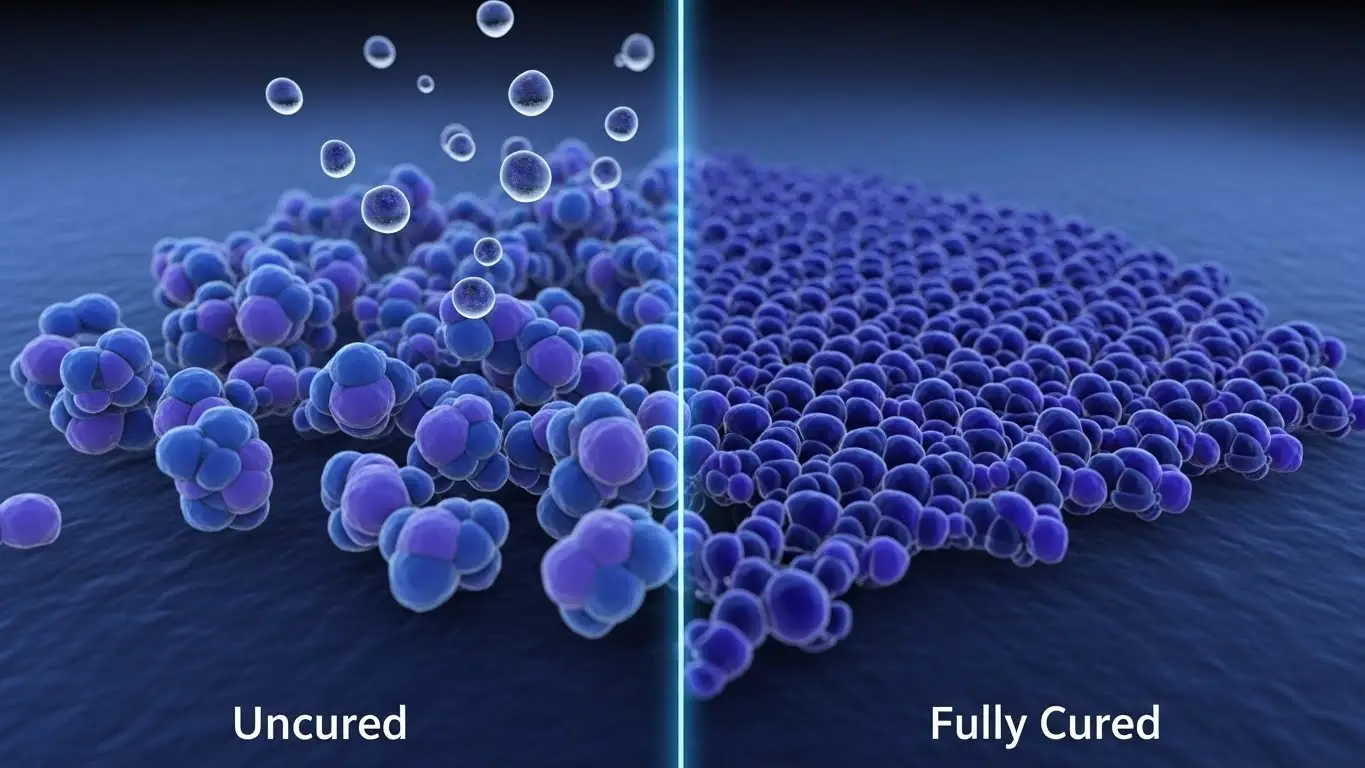

- Uncured Monomers: UV inks are 100% solid systems. If the UV energy doesn't react with every single molecule, you are left with free monomers. These small molecules are volatile and are the number one culprit for that sharp, chemical acrid smell.

- Photoinitiators (PIs): Standard photoinitiators can split into byproducts (like benzaldehyde) that have a distinct almond or burnt odor. This is why standard inks are never recommended for low-odor applications.

- Oxygen Inhibition: Oxygen in the air is a bully; it steals the energy meant for curing the surface of the ink. This leaves a "tacky" surface layer rich in unreacted chemicals that off-gas over time.

How Does LED Curing Reduce Odor Compared to Mercury Lamps?

LED curing reduces odor by eliminating ozone generation and significantly lowering heat transfer to the substrate. Unlike mercury lamps that bombard the web with infrared heat, LED systems offer a "cold cure" that prevents the release of odors from heat-sensitive films, while their narrow wavelength ensures deeper penetration for a more complete cure.

The "Cold Cure" Advantage

I recall a project involving thin shrink film where mercury lamps were literally cooking the substrate. The film didn't just distort; it smelled like burnt plastic. Switching to UV LED Curing for Flexo & Labels solved this instantly.

- No Ozone: Mercury lamps generate ozone (O3), which has a pungent, bleach-like smell and is hazardous to operator health. LED lamps emit UV-A energy (typically 395nm) that does not generate ozone, immediately improving the air quality of the press room.

- Spectral Matching: LED inks are formulated to react specifically to the narrow output of LED chips. This efficiency often leads to a higher degree of cross-linking deep within the ink layer, trapping potential migrants inside the polymer network so they can't release odor.

What Is the Role of Nitrogen Inerting in Reducing Odor?

Nitrogen inerting significantly reduces odor by displacing oxygen at the curing surface, allowing for higher conversion rates of photoinitiators and monomers. By creating an oxygen-free zone, printers can achieve a complete surface cure without using excessive photoinitiators, directly reducing the potential for chemical byproducts and residual odors in the final print.

Overcoming Oxygen Inhibition

If you are serious about "zero odor," nitrogen is your best friend. In standard curing, oxygen blocks the cure at the very top micron of the ink surface. To fight this, ink manufacturers have to load the ink with extra photoinitiators.

However, if you blanket the curing area with nitrogen, you remove the oxygen.

- Lower PI Content: With nitrogen, you can use inks with fewer photoinitiators. Fewer PIs mean fewer odorous byproducts.

- Harder Surface: The surface cures instantly and completely, sealing the ink and preventing lower-layer chemicals from migrating out.

- Data Support: Studies indicate that nitrogen inerting can increase monomer conversion rates by up to 30%.

How Do I Select the Right Inks for Low-Odor Printing?

Select inks explicitly labeled "Low Migration" (LM) or "Low Odor" that are optimized for LED wavelengths (385nm or 395nm). Ensure the ink series adheres to Nestlé Guidance Notes or Swiss Ordinance standards, which strictly limit the use of high-odor photoinitiators and small-molecule monomers known to cause sensory issues.

The Checklist for Ink Selection

Not all "LED inks" are created equal. When sourcing materials, I always ask the supplier for their Statement of Composition (SoC). You want to verify that the ink is free from:

- Benzophenone: A common photoinitiator known for migration and odor risks.

- ITX (Isopropylthioxanthone): Another PI with a history of taint issues.

Recommended Ink Attributes:

- High Reactivity: Designed to cure fully with the specific energy output of your LED system.

- High Molecular Weight: Larger molecules are less likely to migrate or volatilize.

- Dual-Cure Capability: Caution: While some inks claim to work for both mercury and LED, dedicated LED formulations often provide better cross-linking for sensitive applications.

For a deeper dive into the technical definitions, it is worth reading What Is LED UV Curing in Flexo Printing? to understand how the chemistry interacts with the light source.

What Are the Best Practices for Odorless UV LED Printing?

Best practices include maintaining proper lamp irradiance, managing ink film thickness, and controlling press speed to ensure the "Dose" is sufficient for full polymerization. Regular maintenance of the LED array is crucial, as dirty glass windows can reduce UV output, leading to an incomplete cure and residual chemical odors.

Operational Excellence for Low Odor

Even the best ink will smell if it isn't cured properly. Here is the operational framework I recommend for press operators:

1. Manage Ink Density

Thick ink films are harder to cure. The UV light has to penetrate all the way to the base.

Tip: Use high-strength inks that allow for lower anilox volumes (BCM). A thinner film cures faster and more completely.

2. Monitor Irradiance (W/cm²) and Dose (J/cm²)

- Irradiance: The "punch" or intensity of the light. Essential for penetrating opaque colors like blacks and whites.

- Dose: The total energy the ink receives over time.

- Action: Use a radiometer daily. If your LED output drops below 80% of its peak, you risk an incomplete cure.

3. Temperature Control

While LED is "cool," the chemical reaction is exothermic (creates heat). Ensure your chill rollers are functioning to keep the web stable.

4. Hardware Selection

Using the Best UV LED Curing System for Flexo Label Printing ensures you have the necessary peak irradiance to drive the reaction to completion. Under-powered units are the most common cause of "tacky" or smelly prints.

| Factor | Impact on Odor | Action Item |

| Lamp Output | High | Clean lamp windows every shift. |

| Press Speed | Medium | Slow down if dose levels drop. |

| Ink Thickness | High | Use correct anilox BCM. |

| Substrate | Low/Med | Choose primers that aid adhesion. |

Conclusion

Eliminating odor in UV flexo printing is not magic; it is chemistry and physics. By transitioning to LED curing, you eliminate the ozone and heat that plague traditional methods. However, technology alone isn't enough. You must pair high-performance LED systems with low-migration inks and disciplined process control.

When you control the cure, you control the quality.

Ready to upgrade your press?

Evaluate your current setup and consider how the Best UV LED Curing System for Flexo Label Printing can modernize your production line.