UV LED Curing Systems for Coating: Area vs Conveyor

I remember the first time I walked onto a production floor transitioning from traditional mercury arc lamps to uv led curing systems for coating. The difference was immediate—not just in the silence of the fans, but in the sudden drop in ambient heat. For production managers, the shift to UV LED isn't just about "going green"; it's about precision control. But once you’ve decided to upgrade, the next hurdle is structural: Do you need a static Area Curing system or a dynamic Conveyor system?

This decision dictates your throughput, your floor space, and ultimately, the quality of your finish. In this guide, we break down the mechanics, use cases, and ROI of both configurations to help you engineer the perfect line.

What Are UV LED Curing Systems for Coating?

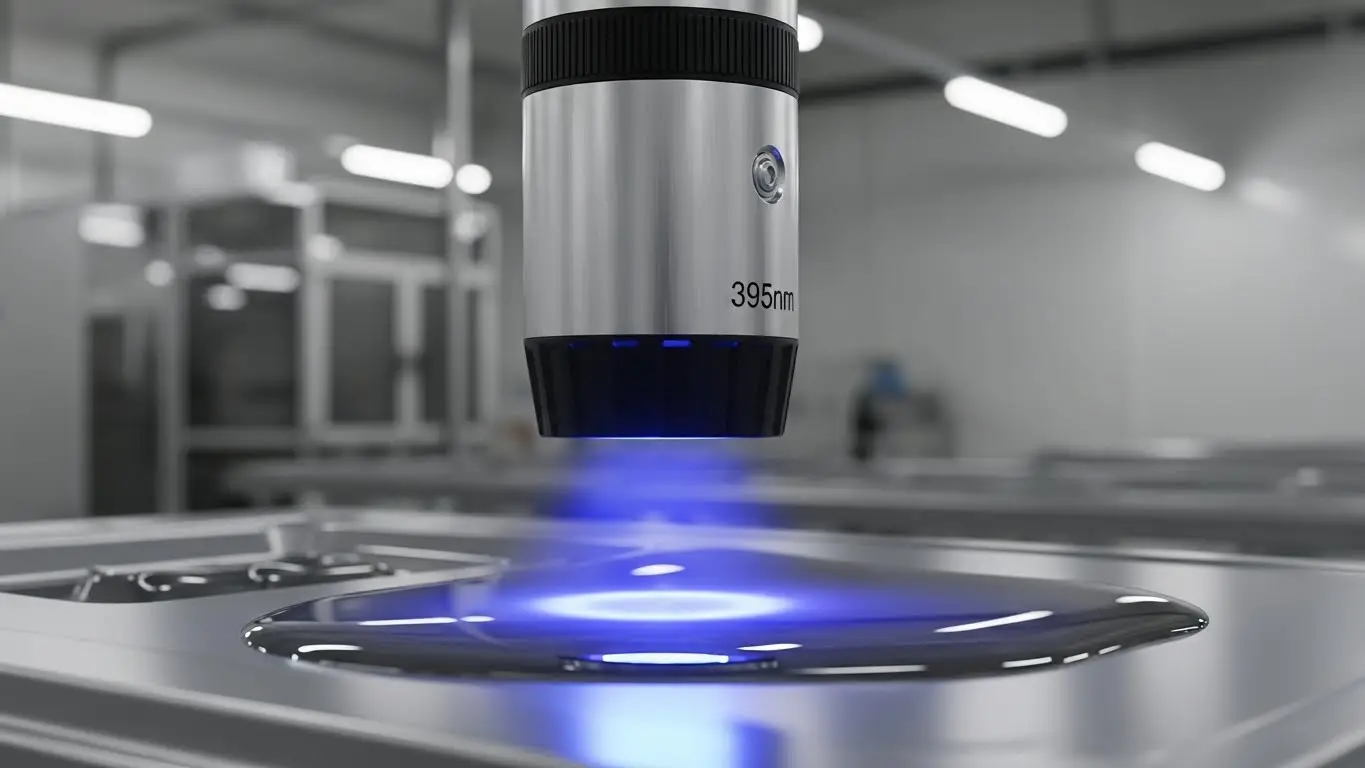

UV LED curing systems for coating use high-intensity light-emitting diodes to instantly polymerize (harden) liquid coatings without the heat or warm-up time associated with mercury lamps. These solid-state systems offer precise control over irradiance and wavelength (typically 365nm, 385nm, 395nm, or 405nm), making them ideal for heat-sensitive substrates and high-speed production lines.

The Shift from Thermal to Photopolymerization

Unlike thermal drying ovens that evaporate solvents over minutes or hours, UV LED curing is a photopolymerization process. It happens in milliseconds. When the specific wavelength of UV light hits the photoinitiators in your coating, they trigger a chain reaction that cross-links oligomers and monomers instantly.

For you, this means:

- Zero Work-in-Progress (WIP): Parts are ready to pack immediately.

- Cold Curing: No warping of thin plastic films or delicate electronics.

- Energy Efficiency: LEDs are instant on/off, consuming energy only when a part is present.

To explore the fundamentals of this technology, check out our deep dive on UV LED Curing for Coatings.

Area vs. Conveyor Curing: Which Architecture Suits Your Line?

The choice between area and conveyor curing depends on your material handling: select Area Curing for static, batch, or complex 3D assembly processes, and Conveyor Curing for continuous, high-volume flat or web-based production. Area systems flood a fixed zone with light, while conveyor systems pass the substrate under a stationary beam for uniform scanning.

The Engineering Behind the Choice

1. UV LED Area Curing (Static/Flood)

Area curing systems, often called "flood" lamps, emit high-intensity UV light over a fixed rectangular footprint (e.g., 100mm x 100mm).

- Best For: Batch processing, lab testing, and stationary assembly stations.

- The "Character" of the Process: I often see these used in "stop-and-go" automation. A robotic arm places a part, the light flashes for 2 seconds, and the arm removes it. It’s surgical precision.

- Key Advantage: It delivers a massive dose of energy (J/cm²) to a specific spot without mechanical movement of the light source.

2. UV LED Conveyor Curing (Dynamic/Scanning)

Conveyor systems integrate the LED lamp head (often a "linear" array) over a moving belt.

- Best For: Continuous manufacturing, electronics potting, flat panels, and roll-to-roll web coating.

- The "Character" of the Process: This is the workhorse of mass production. The belt speed controls the "dwell time" (exposure duration). If you need to cure 5,000 PCBs an hour, you don't stop the line; you flow them under a high-power linear bar.

- Key Advantage: Uniformity. Because the part moves through the light, every inch of the substrate receives an identical exposure profile, eliminating "hot spots" often found in poorly calibrated static setups.

Comparative Analysis: Area vs. Conveyor Systems

Area curing systems excel in high-intensity, localized precision for complex geometries, whereas conveyor systems dominate in uniformity and throughput for flat, continuous high-volume runs.

Use this table to audit your current needs against system capabilities:

| Feature | UV LED Area Curing | UV LED Conveyor Curing |

| Motion Dynamics | Static (Part stops under lamp) | Dynamic (Part moves under lamp) |

| Throughput | Lower (Batch dependent) | High (Continuous flow) |

| Uniformity | High within the spotlight; drops off at edges | Excellent (Scanning averages out variances) |

| Heat Management | Heat can build up if dwell time is long | Airflow from movement aids cooling |

| Typical Application | Camera lens bonding, Lab samples, 3D assembly | PCB conformal coating, Wood finishing, Films |

| Setup Flexibility | High (Easy to mount on robot arms) | Low (Fixed integration into line) |

How Do Heat-Sensitive Substrates Impact Your Choice?

Heat-sensitive substrates like PET, thermal paper, or thin films require the precise "cold cure" of UV LED systems to prevent warping, discoloration, or structural damage. While both Area and Conveyor LED systems reduce heat compared to mercury lamps, conveyor systems often provide superior thermal management due to the airflow generated by the moving belt and shorter exposure times.

The "Thermal Spike" Challenge

Even with LEDs, if you blast a black plastic part with 16W/cm² of energy for 10 seconds in a static Area Curing station, it will get hot. The energy is absorbed by the dark pigment.

- The Solution: For static area curing on sensitive parts, we use "pulsed" modes—flashing the LED at high frequency to allow micro-seconds of cooling between bursts.

- Conveyor Advantage: In a conveyor system, the part is constantly moving away from the heat source. The relative motion acts as a natural cooling mechanism.

If you are struggling with substrate deformation, reviewing our guide on UV LED Curing for Heat-Sensitive Substrates: Best Practices is essential before you finalize your specs.

What Factors Determine the Right Lamp for Your Coating Process?

Selecting the right lamp involves matching the LED's peak wavelength (e.g., 365nm vs. 395nm) to your coating's photoinitiator absorption profile and ensuring the irradiance (W/cm²) is sufficient to penetrate the coating thickness. Mismatched specs lead to "tacky" surfaces or under-cured bottom layers that delaminate later.

1. Wavelength Matching (The Lock and Key)

I cannot stress this enough: You cannot cure a 365nm-formulated coating with a 395nm lamp.

- 365nm: often used for clear coats and adhesives that don't yellow.

- 395nm/405nm: Better penetration for thicker, pigmented, or opaque coatings (like white screen inks).

2. Irradiance vs. Energy Density

- Irradiance (W/cm²): The intensity or "brightness" of the light. Essential for punching through dark pigments.

- Energy Density (Dose - J/cm²): The total amount of light over time.

- Area Systems allow you to easily increase Dose by simply leaving the light on longer.

- Conveyor Systems require you to slow down the belt or add more lamps to increase Dose.

For a detailed breakdown on calculating these values, read: UV LED Coating Curing: Choosing the Right Lamp.

When Should You Choose a UV LED Area Curing System?

Choose a UV LED Area Curing System when your production involves complex 3D geometries, "stop-and-go" automation, or high-intensity spot bonding where the part must remain stationary for precision alignment.

Scenario: The Camera Module Assembly

Imagine you are manufacturing compact camera modules. The lens must be aligned with micron-level precision.

- The Problem: You can't move the part on a conveyor because vibration would ruin the alignment.

- The Solution: An Area Curing lamp mounted on a robotic arm. The arm moves over the stationary part, flashes a high-intensity 365nm burst for 1.5 seconds, and locks the lens in place.

- Why Conveyor Failed: A conveyor would require the part to move, risking the alignment before the glue sets.

Key Area Curing Features:

- Compact Heads: Can be mounted inside tight machinery.

- Programmable Profiles: Step-curing (low power, then high power) to reduce stress in the material.

When is a Conveyor UV LED System the Better Choice?

A Conveyor UV LED System is the superior choice for flat, continuous substrates like PCBs, wood panels, or flexible films where throughput speed and uniform coating consistency are the primary KPIs.

Scenario: The Conformal Coating Line

You are running a line of printed circuit boards (PCBs) coated with a UV-curable protectant.

- The Problem: You have 10,000 boards to process per shift. Stop-and-go curing would create a massive bottleneck.

- The Solution: A variable-speed conveyor with a linear UV LED bar spanning the width of the belt. The boards flow continuously at 2 meters per minute.

- Why Area Failed: An area lamp would require indexing (stopping) every single board, slashing your throughput by 50% or more.

Key Conveyor Features:

- Scalability: Need more cure? Add a second lamp row or slow the belt.

- Safety: Easier to shield effectively as the light is contained within a tunnel.

Technical Specifications to Look For

When requesting a quote for uv led curing systems for coating, having these specs ready will speed up the process:

- Peak Irradiance: Do you need 2W/cm² (standard) or 16W/cm² (high power)?

- Cooling Method:

- Air Cooled: Simpler, but bulky fans. Good for conveyors.

- Water Cooled: Compact heads, silent, but requires a chiller. Standard for high-power Area systems.

- Working Distance: LEDs lose power quickly over distance.

- Area lamps are often calibrated for a 10-30mm working distance.

- Conveyor lamps might need to sit higher (50mm+) to clear components, requiring special optics to focus the beam.

Final Thoughts: Optimizing Your ROI

The transition to uv led curing systems for coating is rarely a question of "if," but "when." The ROI is driven by the elimination of consumables (no mercury bulbs to replace every 1,000 hours) and the dramatic reduction in energy costs.

- If your line is continuous and flat, invest in a robust Conveyor system.

- If your process is precise, geometric, or indexed, a flexible Area system is your best bet.

Your coating process is the final signature on your product's quality. Don't let an outdated curing method be the bottleneck. Evaluate your substrate, measure your throughput needs, and select the architecture that turns your curing station from a pain point into a competitive advantage.