UV LED Coating Curing: Choosing the Right Lamp

Choosing the right UV LED lamp for coating curing primarily depends on matching the lamp’s wavelength (typically 365nm, 385nm, 395nm, or 405nm) to your coating’s photoinitiator profile. A mismatch here leads to incomplete surface cures or poor adhesion. Beyond wavelength, you must calculate the required irradiance (intensity) to penetrate the coating thickness and the energy density (dose) needed for the conveyor speed. For industrial applications, the choice between air-cooled and water-cooled systems is also critical for maintaining stable output during long production runs. Getting this balance right ensures energy efficiency and a consistent, high-quality finish.

What Defines the "Right" UV LED Lamp?

Selecting a curing system isn't just about buying the most powerful light; it is about chemical and physical compatibility. The "right" lamp effectively targets the photoinitiators in your specific UV LED Curing for Coatings formulation without damaging the substrate.

Wavelength Compatibility (The Nanometer Match)

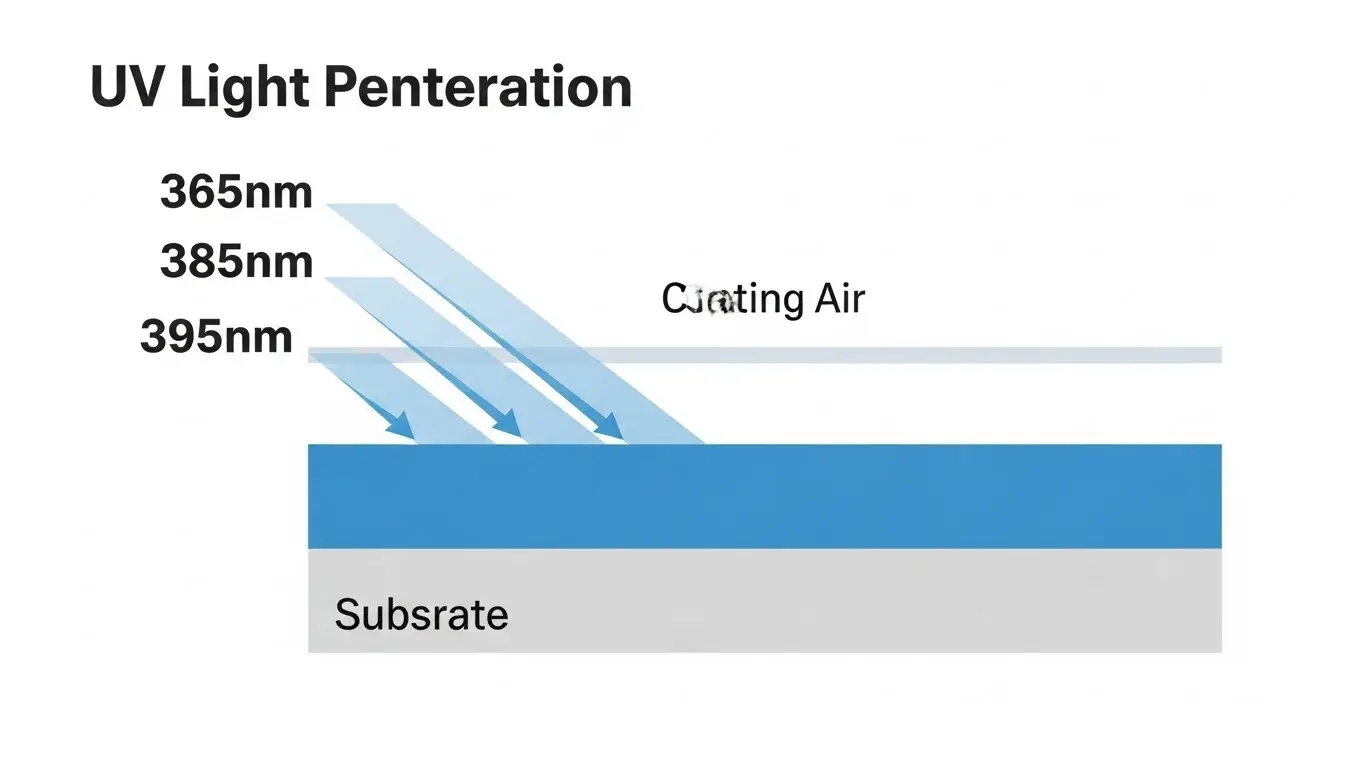

UV LED lamps emit a narrow band of energy, unlike broad-spectrum mercury arc lamps.

- 365nm: ideal for thick coatings and deep curing because it penetrates better. However, these LEDs are often more expensive and less efficient.

- 395nm: The industry standard. It offers the highest intensity and efficiency, making it perfect for general coatings and high-speed lines.

- 405nm: Often used for specific surface curing applications or specialized additive manufacturing.

Pro Tip: Always check the absorption peak of your coating's photoinitiator. If your coating is formulated for a mercury lamp (broad spectrum), it may not cure partially or at all with a 395nm LED lamp unless reformulated.

Irradiance vs. Energy Density

- Irradiance (W/cm²): This is the intensity of the light hitting the surface. High irradiance is necessary to "punch" through pigmented or thick coatings to ensure adhesion at the bottom layer.

- Energy Density (J/cm²): This is the total amount of energy delivered over time. It is determined by the irradiance and the speed of the conveyor.

If you are dealing with fast-moving webs, you need high peak irradiance to achieve the required dose in a fraction of a second.

Optimizing for Substrates and Heat Management

One of the biggest advantages of UV LED technology is the reduction of infrared heat, which allows for processing delicate materials.

Handling Heat-Sensitive Materials

While LEDs run cooler than mercury lamps, the UV energy itself still creates thermal energy upon absorption. For thin films or shrink sleeves, managing this output is vital.

- Pulsed operation: Some lamps can be pulsed to reduce heat buildup.

- Distance control: Adjusting the distance from the substrate affects both heat and irradiance.

For a deeper dive into managing thermal output on delicate materials, refer to our guide on UV LED Curing for Heat-Sensitive Substrates: Best Practices.

Curing on Plastics and Films

When working with non-porous substrates like plastic films, surface tension and cure level are critical. An over-cure can cause brittleness, while an under-cure leads to delamination.

- Oxygen Inhibition: Surface tackiness is a common issue on plastics. Higher irradiance at the surface or using a specific wavelength (like 395nm) often helps overcome oxygen inhibition.

- Flexibility: Ensure the lamp provides a cure that maintains the film's natural flexibility.

Learn more about specific techniques for flexible substrates in our article: How to Cure Coatings on Plastic Film with UV LED.

People Also Ask

What is the difference between 365nm and 395nm UV curing?

The main difference is penetration and efficiency. 365nm penetrates deeper into thick or pigmented layers but is less energy-efficient. 395nm is more efficient, offers higher intensity, and is cheaper, but is generally better suited for surface curing and clearer coatings.

Can UV LED lamps cure standard UV coatings?

Not always. Standard UV coatings are often formulated for the broad spectrum of mercury lamps. To use UV LED, you must ensure the coating contains photoinitiators that react specifically to the LED's narrow wavelength (usually 395nm).

How long do UV LED curing lamps last?

UV LED lamps typically last 20,000 to 30,000 hours of operation. Since they can be turned on and off instantly (unlike mercury lamps which need warm-up time), their effective production lifespan is significantly longer than the rated hours suggest.

System Configuration: Cooling and Integration

Air-Cooled vs. Water-Cooled Systems

Your production environment dictates the cooling method.

| Feature | Air-Cooled | Water-Cooled |

| Intensity | Moderate (up to 12-16 W/cm²) | High (20+ W/cm²) |

| Complexity | Simple (Plug & Play) | Complex (Requires Chiller) |

| Stability | Variable with ambient temp | Highly Stable |

| Form Factor | Larger (needs airflow) | Compact |

| Best For | Lower speeds, narrower widths | High speed, wide web, dirty environments |

Validating Your Cure

Once you have selected a lamp, validation is non-negotiable. You cannot rely on visual inspection alone.

- The Thumb Twist Test: A basic manual check for surface tack.

- Cross-Hatch Adhesion: crucial for ensuring the coating has bonded to the substrate.

- Solvent Rub Test: Verifies chemical resistance.

For a complete testing protocol, read How to Test UV Coating Cure Quality (Adhesion, Rub, Tack).

Troubleshooting Common Issues

Even with the right lamp, things can go wrong. If you notice tackiness or poor adhesion, check your working distance. LEDs have a focal point; being too far away drastically reduces irradiance. Also, ensure your lamp window is clean—mist or dust can block UV energy.

If you are experiencing soft under-layers, your wavelength might be too short (unable to penetrate) or your intensity too low. See our guide on What Causes Incomplete Cure in UV Coatings (And How to Fix It) for detailed troubleshooting steps.

Frequently Asked Questions

Do UV LED lamps produce ozone?

No, UV LED lamps do not produce ozone. Ozone is generated by short-wave UV (below 240nm), which is present in mercury lamps but absent in the narrow spectrum of UVA LEDs. This eliminates the need for expensive exhaust systems.

Can I retrofit an existing machine with UV LED?

Yes, retrofitting is common. UV LED heads are typically more compact than mercury arc systems. However, you must update the power supply and ensure the machine's PLC can communicate with the new LED controller.

Is higher irradiance always better?

No. Excessive irradiance can damage heat-sensitive substrates or cause "skinning," where the surface cures so fast it traps liquid coating underneath. The goal is the optimal irradiance for your specific chemistry.

How much energy can I save by switching to UV LED?

Manufacturers typically see energy savings of 50% to 70%. This comes from the LED's higher efficiency and the ability to turn the lamps off instantly whenever the production line stops.

Key Takeaways

- Match the Wavelength: Ensure your lamp's wavelength (e.g., 395nm) aligns with your coating's photoinitiators.

- Calculate Irradiance: High speed and thick coatings require higher peak irradiance (W/cm²) for a full cure.

- Manage Heat: Use water-cooled systems for high-intensity, stable output, especially on fast lines; use air-cooled for simpler setups.

- Validate the Process: Regularly test cure quality using adhesion and rub tests to ensure lamp performance hasn't drifted.

Conclusion

Choosing the right UV LED coating curing lamp is a balance of chemistry, physics, and production logistics. By focusing on wavelength compatibility and proper energy density, you can achieve a faster, more consistent cure while lowering your energy footprint.

Ready to optimize your curing process? Contact us today to discuss which UV LED configuration fits your specific production line.