How to Cure Coatings on Plastic Film with UV LED

Knowing how to cure coatings on plastic film with UV LED technology is becoming the gold standard for manufacturers who need speed, precision, and energy efficiency without damaging heat-sensitive substrates. In the competitive world of converting and packaging, shifting from traditional mercury lamps or thermal drying to UV LED systems isn't just an upgrade—it's a transformation. By utilizing a "cold" curing process, you can process thinner, more delicate films like PET, BOPP, and PE at higher speeds than ever before. This guide dives deep into the technical nuances, overcoming adhesion challenges, and optimizing your production line for flawless results.

What Is UV LED Curing for Plastic Films?

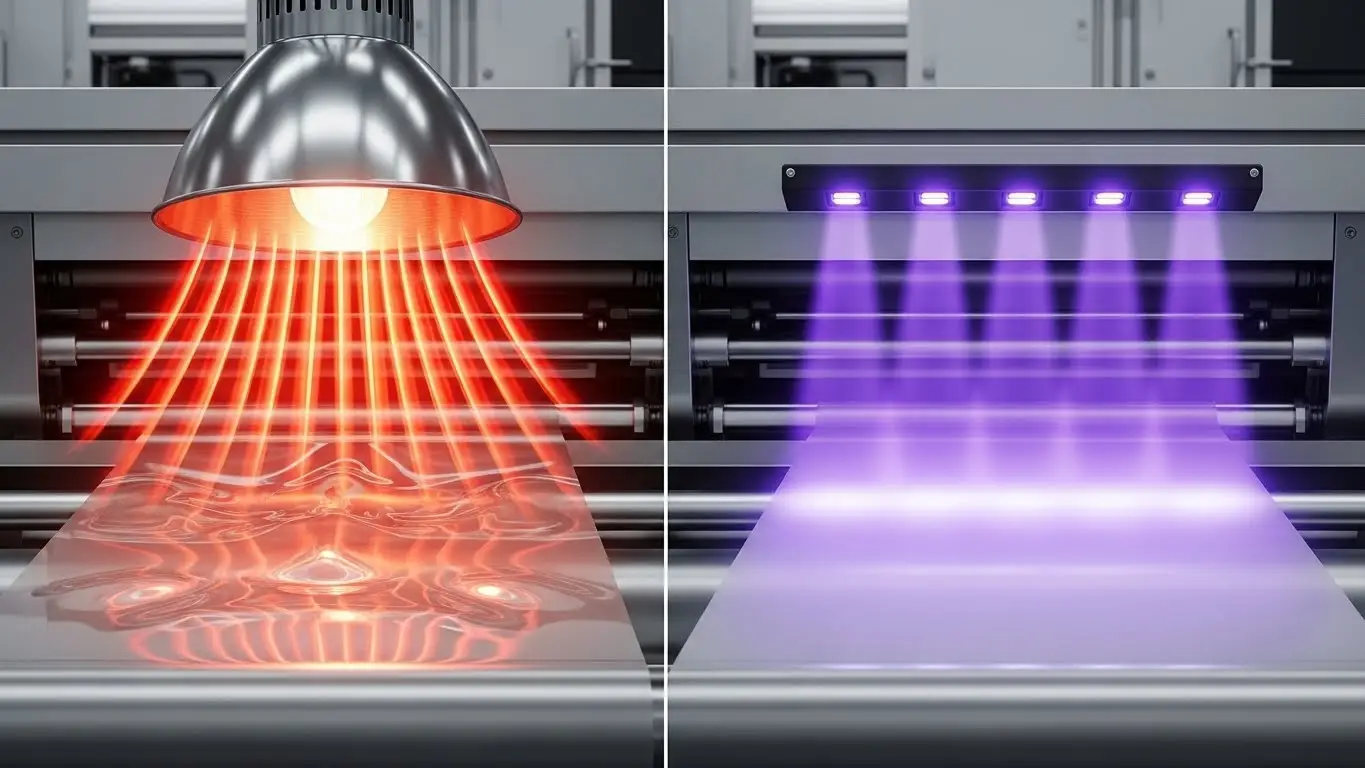

UV LED curing for plastic films is a photopolymerization process that uses high-intensity ultraviolet light-emitting diodes to instantly harden liquid coatings, inks, or adhesives on heat-sensitive substrates. Unlike mercury lamps, UV LEDs emit a narrow, monochromatic wavelength (typically 365nm, 385nm, or 395nm) that triggers photoinitiators without generating the damaging infrared heat that warps or shrinks plastic films.

The Shift from Thermal to "Cold" Curing

For decades, curing coatings on plastic film was a balancing act. You needed enough energy to cross-link the polymer but had to carefully manage the heat to avoid "blocking" (where the film sticks to itself) or distortion. Traditional medium-pressure mercury arc lamps emit a broad spectrum of light, including a significant amount of infrared (IR) energy. This IR energy is wasted heat that transfers directly to your plastic web.

UV LED systems solve this by emitting cool, focused energy. The LEDs turn electrical energy directly into UV light with minimal heat transfer to the substrate. This allows you to:

- Run Heat-Sensitive Films: Process thin gauge shrink films and electronics films that would degrade under thermal ovens.

- Eliminate Chill Rolls: In many cases, the reduced heat load removes the need for expensive, space-consuming chill rollers.

- Instant On/Off: UV LEDs require no warm-up time. You can switch them off instantly when the line stops, preventing the burning of the stationary web—a common headache with hot mercury lamps.

How Does the UV LED Curing Process Work on Plastic?

The process works by matching the UV LED's specific wavelength output to the photoinitiators in the coating, causing an instant chemical reaction that transforms the liquid into a cross-linked solid. As the plastic film passes under the LED array, the high irradiance penetrates the coating layer, initiating polymerization in milliseconds while leaving the underlying plastic unaffected by thermal stress.

Step-by-Step Curing Workflow

To achieve a perfect cure on plastic film, the process must be tightly controlled. Here is the typical workflow:

- Surface Preparation: Plastic films often have low surface energy (measured in dynes). Before coating, the film usually undergoes corona or plasma treatment to increase surface energy and improve wetting.

- Coating Application: The liquid formulation (varnish, hard coat, or adhesive) is applied via gravure, flexo, or slot-die methods.

- Wavelength Matching: The formulation must contain photoinitiators that absorb energy at the LED’s specific peak (e.g., 395nm). Note: Using a formulation designed for mercury lamps (broad spectrum) with an LED lamp often leads to surface tackiness.

- Exposure: The film passes under the UV LED lamp head. The distance is critical; the lamp is typically mounted 5–10mm from the web to maximize peak irradiance.

- Cross-Linking: The photoinitiators absorb the photons, creating free radicals that link monomers and oligomers into a hardened polymer network.

- Quality Control: The film is tested for adhesion (tape test) and cure level (solvent rub test) immediately after the lamp.

| Feature | UV LED Curing | Traditional Mercury Curing |

| Heat Transfer | Minimal (Cold Cure) | High (Requires Chill Rolls) |

| Warm-Up Time | Instant (0 seconds) | Slow (10-20 minutes) |

| Energy Consumption | Low (Significant savings) | High |

| Bulb Lifespan | 20,000+ Hours | 1,000 - 2,000 Hours |

| Ozone Generation | None | High (Requires Exhaust) |

What Coatings Can Be Cured with UV LED?

UV LED technology can cure a wide range of coatings on plastic, including acrylates, silicones, and specialized protective varnishes, provided they are formulated with LED-specific photoinitiators. The most common applications include functional hard coats for displays, soft-touch coatings for packaging, and high-gloss varnishes for label protection.

Formulating for the Spectrum

The success of your curing process depends entirely on the chemistry. Because UV LEDs are monochromatic (emitting light in a very narrow band), you cannot use "off-the-shelf" general UV coatings.

- Free-Radical Acrylates: The workhorse of the industry. These cure very fast and are ideal for high-speed web lines.

- Cationic Epoxies: These cure slower but offer excellent adhesion and low shrinkage, which is vital for plastics that might curl. However, they are harder to cure with LED alone without sensitization.

- Dual-Cure Systems: Some modern formulations combine mechanisms to ensure surface cure (preventing oxygen inhibition) and deep through-cure.

If you are transitioning your line, you must consult your chemical supplier to ensure your varnish or coating is "LED-ready."

For a deeper dive into compatible chemistries, read our guide on What Coatings Can Be Cured with UV LED?

How Do You Overcome Adhesion Challenges on Plastic Films?

You overcome adhesion challenges by increasing the substrate's surface energy through corona or plasma treatment and ensuring the coating's surface tension is lower than that of the treated plastic. Additionally, selecting a UV LED coating with low shrinkage properties is vital, as high shrinkage during rapid curing can pull the coating away from the smooth plastic surface, leading to delamination.

The "Wetting" Problem

Plastic films like Polypropylene (PP), Polyethylene (PE), and Polyester (PET) are naturally non-porous and chemically inert. If you apply a UV coating directly, it will likely bead up or peel off like a sticker.

Best Practices for Adhesion:

- In-Line Corona Treatment: Install a corona treater immediately before the coating station. This "roughens" the molecular surface of the plastic, creating bonding sites.

- Anchor Coatings (Primers): For difficult substrates, applying a thin water-based or UV primer can act as a bridge between the plastic and the topcoat.

- Nitrogen Inerting: Oxygen inhibits the curing of the surface layer, leaving it tacky. On high-speed film lines, flooding the cure zone with nitrogen displaces oxygen, allowing for a harder, faster cure and better chemical resistance.

Can UV LED Cure Powder Coating on Plastic Film?

Yes, UV LED can cure powder coatings on plastic film, but it requires a specialized process where the powder is melted at low heat (via IR) before being instantly cross-linked by UV LED light. This separation of the "melt" and "cure" phases prevents the plastic film from being exposed to the high temperatures required for traditional thermal powder coating (typically 400°F/200°C).

The UV Powder Advantage

Standard powder coating destroys plastic film. UV-cured powder coating changes the game:

- Melt Phase: The powder is applied electrostatically and melted at a low temperature (100°C - 130°C) for a short time, just enough to flow into a smooth film.

- Cure Phase: The part moves under the UV LED lamp. The curing happens in seconds.

This is revolutionary for industries wanting the durability of a powder coat on heat-sensitive materials like MDF or heavy-gauge plastic sheets.

Curious about this specific application? Learn more at Can UV LED Cure Powder Coating?

UV LED Curing for UV Varnish: How It Works

UV LED curing for varnish involves applying a clear, protective liquid layer over printed text or graphics and exposing it to UV LED light to create an instant, high-gloss, or matte finish. This process is widely used in narrow web label printing and flexible packaging to protect inks from abrasion, moisture, and chemicals while adding shelf appeal.

Optimizing Varnish Curing

Varnishes are often thicker than ink layers, which poses a challenge for "through-cure" (curing all the way to the bottom).

- Wavelength Penetration: Longer wavelengths like 395nm penetrate deeper into thick varnish layers than shorter wavelengths (like 365nm), ensuring good adhesion to the base film.

- Surface Cure Issues: Sometimes, 395nm is too penetrating and doesn't cure the very top surface efficiently, leaving it sticky.

- The Hybrid Solution: Many advanced lines use a mix of LED arrays (e.g., a 365nm bar for surface sealing and a 395nm bar for deep adhesion) or specialized additives in the varnish to ensure a hard, dry surface.

For detailed technical specs on varnish applications, check out UV LED Curing for UV Varnish: How It Works

Key Implementation Tips for Your Production Line

Integrating UV LED into your film line requires attention to detail. Here are the expert tips to ensure you get it right the first time.

Manage the "Oxygen Inhibition" Zone

As mentioned, oxygen is the enemy of surface cure. If your film feels tacky despite high power settings, you are likely suffering from oxygen inhibition.

- Solution: Increase the photoinitiator concentration in your coating or use a nitrogen blanket system to purge oxygen from the curing area.

Control the Distance

UV LED irradiance drops off quickly over distance.

- Rule of Thumb: Keep the lamp head within 2mm to 10mm of the film surface. If the web flutters, stabilize it with a roller; do not just move the lamp further away, or you will lose curing power.

Monitor Thermal Management

Even though LEDs are "cool," the chemical reaction of curing is exothermic (creates heat).

- Tip: On extremely thin films (under 12 microns), ensure you have a chilled backing roller to absorb the heat generated by the polymerization reaction itself, even if the lamp isn't emitting IR heat.

Optimize Line Speed

Don't just crank the lamp to 100% and hope for the best.

- Strategy: Perform a "ladder study." Run the line at different speeds and power levels to find the "cure window"—the range where the coating is fully cured but energy isn't wasted. You might find that lower power is sufficient, extending the life of your equipment.

Conclusion

Mastering how to cure coatings on plastic film with UV LED is about leveraging the precision of narrow-spectrum light to process materials that were previously impossible to cure thermally. By eliminating infrared heat, you unlock the ability to run thinner, cheaper, and more sustainable films while reducing your factory's energy footprint.

Whether you are applying a simple protective varnish or a complex functional hard coat, the keys to success are surface preparation, correct formulation chemistry, and precise lamp integration.

Ready to upgrade your production capabilities? Explore the full range of solutions and deep-dive technical resources at UV LED Curing for Coatings.