How to Test UV Coating Cure Quality (Adhesion, Rub, Tack)

To test UV coating cure quality effectively, you must evaluate three primary factors: surface cure (tack), through-cure (chemical resistance), and adhesion. The most practical on-site method is the Thumb Twist Test, where you press and twist your thumb on the surface; a properly cured coating should show no marring or tackiness. For measurable validation, use the Solvent Rub Test (MEK) to check chemical resistance (ASTM D5402) and the Cross-Hatch Tape Test to verify adhesion to the substrate (ASTM D3359). Combining these sensory and physical tests ensures the coating has reacted fully and bonded correctly.

Why Testing Cure Quality Matters

Ensuring your UV curing process is dialed in is critical for product longevity. An under-cured coating might look dry, but it can fail later due to poor adhesion or lack of scratch resistance.

When implementing UV LED Curing for Coatings, relying solely on visual inspection is risky. You need a combination of non-destructive checks and rigorous physical testing to guarantee the photoinitiators have fully reacted with the oligomers.

Quick Summary of Test Types

- Tactile: Thumb Twist, Fingernail Scratch.

- Chemical: MEK Rub Test (Solvent Resistance).

- Physical: Cross-Hatch Adhesion, Pencil Hardness.

The First Line of Defense: Tactile and Visual Testing

Before breaking out the chemicals, use your senses. These "shop floor" tests are fast indicators of gross under-curing.

The Thumb Twist Test

This is the most common quick check. Place your thumb firmly on the coating and twist it 90 degrees.

- Pass: The surface remains smooth, and no fingerprint is visible.

- Fail: The surface feels tacky, shows a print, or the coating detaches.

The Fingernail Scratch

Run the back of your fingernail across the surface. If it leaves a mark or gouges the material, the "through-cure" (hardening deep within the layer) is likely insufficient. This is particularly relevant for thick layers, such as when you apply UV LED Curing for UV Varnish.

The Solvent Rub Test (MEK Resistance)

What is the MEK rub test? This is the industry standard for determining if a coating is chemically cross-linked (cured).

How to Perform the Test (ASTM D5402)

You use a cloth soaked in Methyl Ethyl Ketone (MEK) and rub the surface back and forth with moderate pressure.

- Soak: Saturate a cheesecloth with MEK.

- Rub: Perform "double rubs" (one forward and back motion counts as one).

- Count: A standard pass often requires 50–100 double rubs depending on the spec.

- Inspect: Look for gloss loss, softening, or removal of the coating.

If the coating dissolves or softens significantly, the cross-linking density is low. This is a major red flag and often leads operators to investigate What Causes Incomplete Cure in UV Coatings (And How to Fix It).

Adhesion Testing (Cross-Hatch Method)

Adhesion is often the first thing to fail on difficult substrates like plastics or metals. Even a hard coating is useless if it peels off.

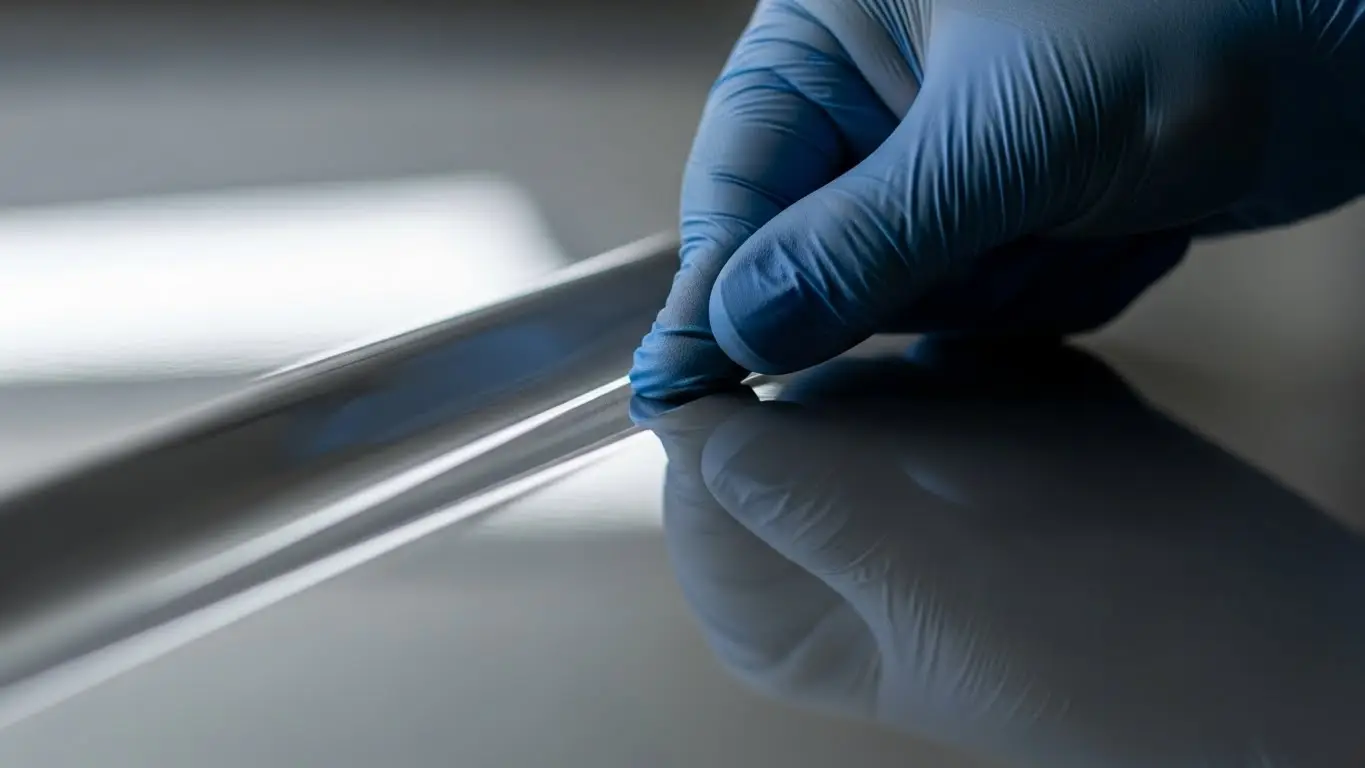

The Cross-Hatch Tape Test (ASTM D3359)

This test is essential when learning How to Cure Coatings on Plastic Film with UV LED, as flexible substrates are prone to delamination.

- Cut: Use a cross-hatch cutter to score a grid pattern through the coating down to the substrate.

- Tape: Apply pressure-sensitive tape (like Permacel 99) over the grid.

- Pull: Remove the tape rapidly at a 180-degree angle.

- Rate: Classify the result from 0B (massive flaking) to 5B (perfect edges, no removal).

Comparison of Cure Test Methods

Different applications require different testing rigors. Here is how they stack up:

| Test Method | Type | Best For | Speed | Destructive? |

| Thumb Twist | Tactile | Quick production line checks | Instant | No |

| MEK Rub | Chemical | Verifying chemical resistance | Fast (2-5 mins) | Yes |

| Cross-Hatch | Physical | Adhesion to substrate | Moderate (5-10 mins) | Yes |

| FTIR Spectroscopy | Lab Analysis | Scientific % of conversion | Slow (Lab required) | No |

How do you know if UV resin is cured?

Short Answer: You know UV resin is cured when it is hard, dry to the touch, and produces no odor.

Expanded Details:

If the resin remains sticky (tacky) after the light cycle, it usually indicates "oxygen inhibition"—where air prevents the very top layer from curing. This is distinct from the bulk cure. To fix this, you may need higher intensity light or a nitrogen purge. Also, ensure you aren't confusing liquid resin with powder; for example, people often ask Can UV LED Cure Powder Coating?—the answer involves different chemistry and testing protocols compared to liquid resins.

What causes UV coating to be sticky?

Short Answer: Stickiness is usually caused by oxygen inhibition, old UV lamps, or applying the coating too thick.

Expanded Details:

When UV energy is too low (perhaps due to lamp degradation), the photoinitiators cannot start the chain reaction effectively. Furthermore, on certain heat-sensitive materials, operators might dim the lamps to save the substrate, inadvertently causing an under-cure. If you are experiencing this, refer to our guide on What Causes Incomplete Cure in UV Coatings (And How to Fix It) for a troubleshooting checklist.

Frequently Asked Questions

Q: Can I over-cure a UV coating?

A: Yes. Over-curing can make the coating brittle, leading to cracking or yellowing. It can also cause adhesion failure because the coating shrinks too much, pulling away from the substrate.

Q: How does UV LED differ from mercury lamps regarding cure quality?

A: UV LED provides a narrow bandwidth (usually 365nm, 385nm, or 395nm). This means you must match your photoinitiators exactly to the LED output. If mismatched, the coating will not cure regardless of the intensity.

Q: What is the potassium permanganate test?

A: This is a test used specifically for clear UV varnishes. Potassium permanganate stains uncured acrylate groups brown. It visualizes under-cured areas that look fine to the naked eye.

Q: Is the smell of the coating an indicator of cure?

A: Yes. Uncured acrylates have a distinct, pungent odor. If your finished product smells strong, it is likely under-cured, and unreacted monomers are "outgassing."

Key Takeaways

- Start Simple: Use the Thumb Twist test for immediate, non-destructive feedback on the production line.

- Verify Chemistry: Use the MEK Rub test to ensure the coating has cross-linked and provides chemical resistance.

- Check Adhesion: Always perform a Cross-Hatch test (ASTM D3359), especially on plastic films or non-porous substrates.

- Match the Source: Ensure your UV LED wavelength matches the coating formulation to prevent under-curing issues.

Conclusion

Testing UV coating cure quality doesn't always require an expensive laboratory. By implementing a routine that includes tactile checks for surface tack and physical tests for adhesion and solvent resistance, you can catch quality issues before they leave the factory.

Ready to upgrade your curing consistency? Explore our solutions for UV LED Curing Systems to ensure a perfect cure every time.