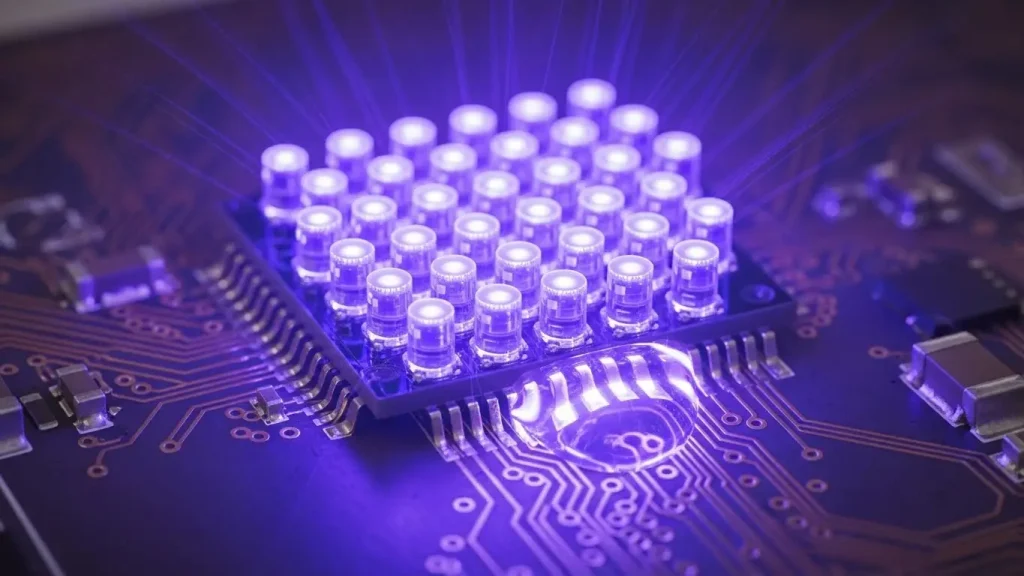

UV LED Curing Wavelength Guide: 365 nm vs 385 nm vs 395 nm vs 405 nm

You need a reliable UV LED curing wavelength guide to understand how specific light frequencies impact your manufacturing results. Selecting the right wavelength is a technical decision that determines if your adhesives and coatings reach their full structural strength. This guide covers the essential differences between 365 nm, 385 nm, 395 nm, and 405 nm to help you align your light source with your material chemistry. By matching these frequencies to your photoinitiators, you can improve your production speed and ensure a consistent finish on every part.

Why Wavelength Matters in UV LED Curing

Wavelength matters because it determines how curing energy interacts with materials and photoinitiators. You must match the light output of your lamp to the absorption profile of your chemistry to start the polymerization process. If your wavelength is off, the energy will pass through the material or reflect off the surface without causing the liquid to harden. Your choice of frequency also dictates how deep the light can travel through your coating. Shorter wavelengths and longer wavelengths interact with pigments and resins in different ways, affecting the final bond strength.

What Are the Characteristics of 365 nm UV LED Curing?

The 365 nm wavelength provides deeper penetration and is effective with specific photoinitiators sensitive at that range. You often use this frequency when you need to cure through thick layers of clear coatings or when working with specialized industrial adhesives. It offers a strong energy "punch" that helps you achieve a solid bond on the substrate level. Many traditional UV chemistries were originally designed for the 365 nm peak found in mercury lamps. Using this wavelength in your LED setup allows you to maintain compatibility with a wide range of existing resins.

What Are the Characteristics of 385 nm UV LED Curing?

The 385 nm wavelength balances penetration and surface cure for a variety of materials. You will find that this frequency acts as a versatile middle ground, offering enough depth for thicker layers while still providing enough surface energy to prevent tackiness. It is a reliable option when your shop handles several different types of parts on the same line. You get a broader range of compatibility with this wavelength compared to more extreme frequencies. It works well with many "dual-cure" photoinitiators that respond to a slightly wider band of UV light.

What Are the Characteristics of 395 nm UV LED Curing?

The 395 nm wavelength is widely used for general curing applications due to its common photoinitiator alignment. You see this frequency used most often in digital printing, wood finishing, and general assembly because many modern inks are tuned specifically for it. It offers high energy efficiency and is easy to find in most standard industrial lamp configurations. When you use 395 nm, you gain a mainstream tool that handles the bulk of common industrial tasks. It is particularly good at curing through dark or heavily pigmented inks where shorter wavelengths might be blocked.

What Are the Characteristics of 405 nm UV LED Curing?

The 405 nm wavelength provides efficient surface cure with reduced penetration compared to shorter wavelengths. You use this frequency when your primary goal is to achieve a hard, scratch-resistant finish on the very top of your product. It is often used in combination with other wavelengths to ensure a part is dry to the touch immediately after it leaves the light. Because this wavelength is closer to the visible light spectrum, it can be safer for certain delicate materials that might degrade under harsher UV light. You often find it in use for 3D printing resins and specific medical-grade glues.

How Should You Match Wavelength to Material Photoinitiators?

Matching the curing wavelength to material photoinitiators supports effective and consistent cure. You should always consult your material data sheet to find the "peak absorption" of your resin or ink. Your goal is to pick a lamp that emits light exactly at that peak to ensure the chemical reaction starts as fast as possible.

- Check your ink's data sheet for its required UV spectral range.

- Confirm your lamp's peak output matches the material's needs.

- Test a sample under the light to verify surface hardness.

- Ensure the wavelength reaches the bottom of your specific coating thickness.

When your light and chemistry are perfectly matched, you use less power and generate less heat. This alignment prevents common production errors like "skinning," where only the top layer is hard while the bottom stays wet.

What Are the Practical Trade-Offs Between Shorter and Longer Wavelengths?

Choosing between shorter and longer wavelengths involves balancing cure depth, speed, and material compatibility. You might find that a shorter wavelength like 365 nm gives you a deeper bond but requires more specialized chemistry. A longer wavelength like 395 nm might be easier to source but could require more power to cure the surface of certain coatings. You must also consider the heat sensitive nature of your substrates. While all LEDs are cooler than old lamps, different wavelengths can interact with your materials in ways that affect their final shape.

What Are the Key Takeaways on UV LED Wavelength Selection?

Your choice of wavelength depends on the specific chemical needs of your coating and the depth of cure required for your parts. You should prioritize matching your lamp to your photoinitiators to ensure your process stays stable and efficient.

- 365 nm is your choice for deep penetration and legacy chemistry.

- 395 nm is the mainstream choice for most modern inks and high-speed lines.

- 385 nm and 405 nm offer specialized balance for surface cure and specific resins.

- Successful curing requires a perfect match between your light and your material.

What Are the Practical Differences Between 365 nm and 395 nm UV LED Curing?

You will notice distinct changes in how your parts dry when you compare these two. You can find a detailed breakdown of the 365nm vs 395nm UV LED curing results to see which fits your shop floor. This helps you understand why one might leave a tacky finish while the other creates a deep bond.

What Is Distinctive About 385 nm UV LED Curing?

The 385 nm range offers a unique spectral profile that fits between the deep penetration of shorter waves and the surface focus of longer ones. You can learn more about its specific behavior on our 385nm UV LED curing and 385nm UV LED curing light pages.

What Practical Uses Are There for 405 nm UV LED Curing?

You often see this frequency in very specific industrial roles, such as dental resins or 3D printing. Explore the 405nm UV LED curing applications to see if this wavelength can help you achieve a better surface finish on your parts.

How Does Photoinitiator Matching Improve Cure Consistency?

When you align your light to your chemistry, your rejection rate drops. You can read about the best practices for photoinitiator matching with UV LED wavelengths to ensure your bond is always strong. This step is vital for meeting your quality standards every shift.

How Does Wavelength Affect Cure Depth and Uniformity?

Understanding how light travels through a liquid coating is a key part of your job. Check our guide on UV LED wavelength and cure depth to see how to avoid sticky spots. This ensures that every layer of your material gets the energy it needs.

What Should You Consider When Choosing a UV LED Wavelength?

You should follow a structured path when picking your frequency to avoid costly equipment mistakes. We have created a guide to help you choose a UV LED wavelength based on your actual shop conditions. This checklist ensures you cover your material, speed, and safety needs.

What Should You Know About 395 nm UV LED Lamps?

If you are leaning toward the most common industrial frequency, you should know its limits and strengths. Look at our technical notes on the 395nm UV LED curing lamp to see how it fits into modern production lines. It is a proven tool for many high-volume tasks.

What Should You Know About 365 nm and Other UV LED Curing Lights?

Choosing a 365 nm source often requires a different equipment setup than longer wavelengths. You can explore the hardware details on our 365nm UV LED curing light page. This information helps you visualize the gear you will need on your conveyor.

Final Thoughts

Selecting the correct wavelength is the single most important step in moving from a general lighting setup to a high-precision curing process. As you advance your production capabilities, you will find that even a small shift in nanometers can significantly change your adhesion quality and through-cure performance. By utilizing this wavelength guide and consulting with your material suppliers, you can build a stable, efficient, and reliable manufacturing environment. Your goal is to eliminate the guesswork and rely on the technical alignment between your light source and your chemistry to drive your production success.