What Is a UV LED Conveyor Curing System? (The 2026 Industry Guide)

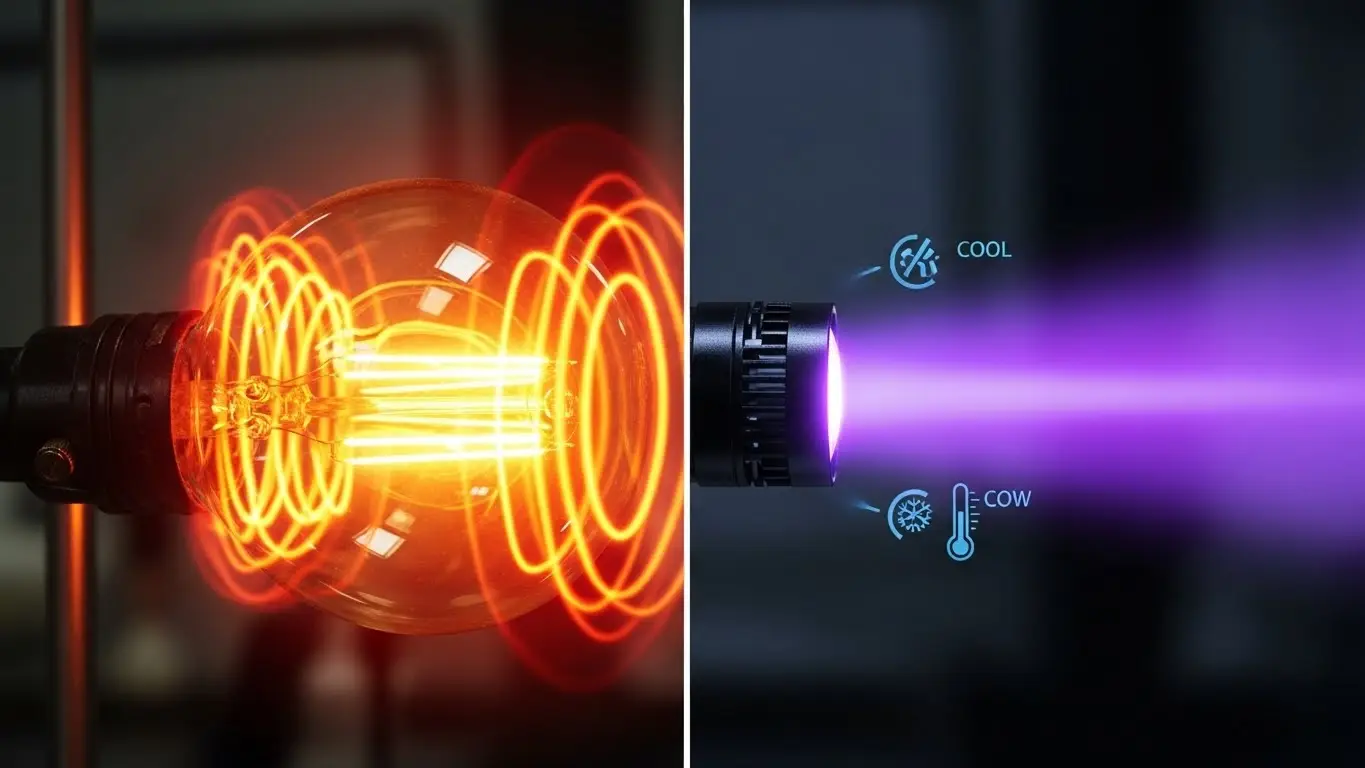

A UV LED conveyor curing system is an industrial machine that uses light-emitting diodes (LEDs) to instantly dry or harden adhesives, inks, and coatings on products moving along a continuous belt. Unlike traditional mercury lamps that rely on broad-spectrum heat and light, UV LED systems utilize specific wavelengths for "cold curing," significantly reducing energy consumption and preventing thermal damage to sensitive materials.

In this guide, you will learn:

- The Mechanics: How LED arrays interact with photoinitiators for instant bonding.

- The ROI: Why manufacturers are saving up to 70% on energy costs.

- Wavelength Selection: The critical difference between 365nm, 395nm, and 405nm.

- Integration: How to size belt speed and intensity for your specific production line.

- Troubleshooting: Avoiding common pitfalls like oxygen inhibition and surface tackiness.

How Does a UV LED Conveyor Curing System Work?

At its core, the process relies on a chemical reaction called photopolymerization. When the UV light hits the liquid material (ink, adhesive, or coating), it activates photoinitiators that instantly cross-link polymers, turning the liquid into a solid.

A conveyorized system standardizes this process for mass production through three key components:

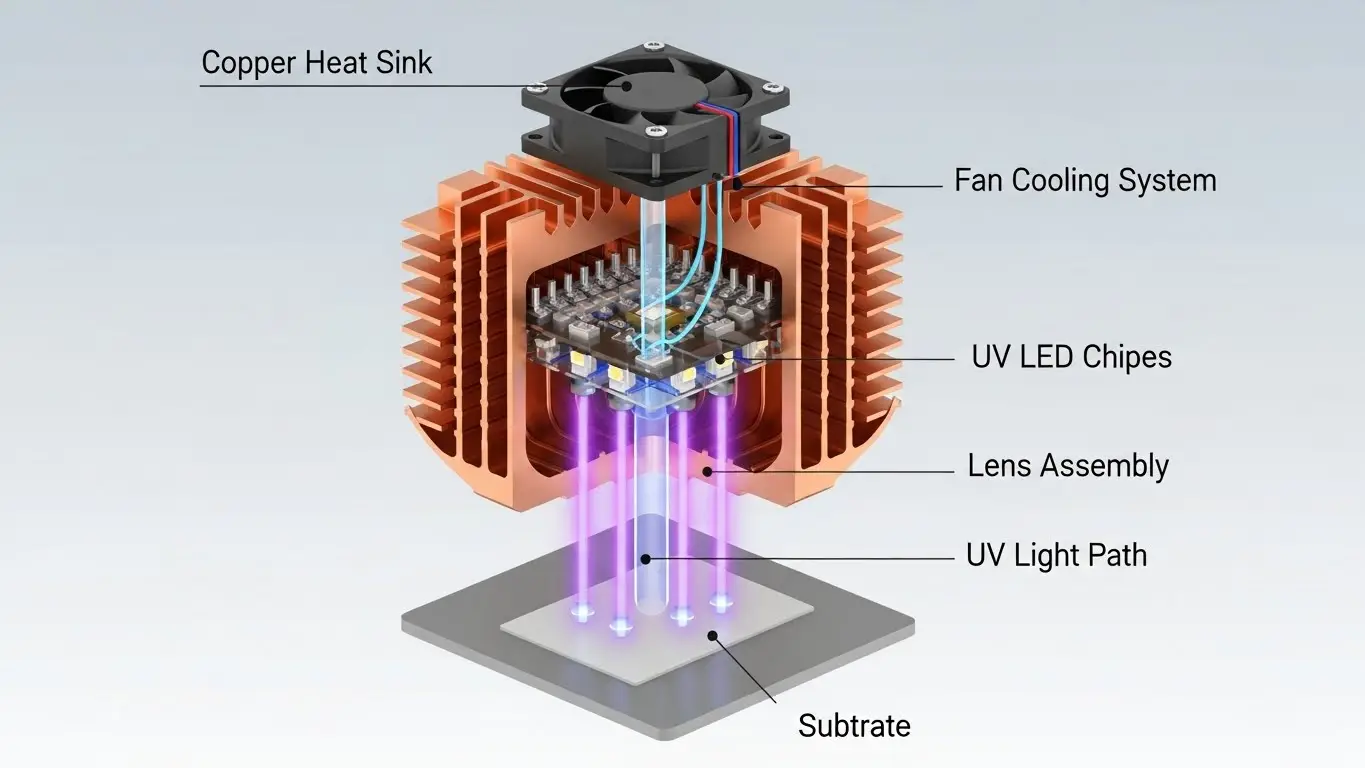

1. The LED Array (The Light Source)

Instead of a single bulb, these systems use an array of high-intensity LED chips. These chips emit a narrow, monochromatic band of UV light (e.g., exactly 365nm). This precision allows for higher peak irradiance (W/cm²) without the wasted infrared heat generated by older systems.

2. Conveyor Mechanism & Speed Control

Consistency is vital for quality control. The conveyor belt moves products under the light source at a strictly controlled speed, often managed by a variable frequency drive (VFD). This ensures every part receives the exact same "dose" of energy (measured in mJ/cm²).

- Belt Materials: Typically Teflon-coated fiberglass (for general use/high temp) or Stainless Steel Mesh (for vacuum hold-down or static-sensitive parts).

3. Thermal Management

Even though LEDs run cooler than mercury bulbs, the chips themselves generate heat that must be dissipated to maintain intensity.

- Air-Cooled: Uses fans and heat sinks; ideal for standard widths.

- Water-Cooled: Uses a chiller; necessary for high-power, wide-format systems to maintain stable UV output over long shifts.

UV LED vs. Mercury Arc Conveyors: The Big Comparison

For decades, mercury arc lamps were the standard. However, the shift to LED is accelerating due to environmental regulations and operational costs.

| Feature | UV LED System | Mercury Arc System |

| Warm-up Time | Instant On/Off (0 seconds) | 10–30 Minutes |

| Heat Emission | Low (Cold Curing) | High (Risk of warping parts) |

| Bulb Lifespan | 20,000+ Hours | 1,000–2,000 Hours |

| Energy Usage | Low (Up to 70% savings) | High (Always on) |

| Ozone Generation | None (No exhaust required) | Yes (Requires extraction) |

| Spectrum | Narrow/Specific (e.g., 395nm) | Broad Spectrum |

The "Cold Curing" Advantage

Because LEDs do not emit infrared radiation, the substrate surface temperature remains low. This is critical when curing coatings on heat-sensitive materials like thin plastic films or electronic components. For a deeper dive into coating applications, read our guide on UV LED Curing for Coatings.

Top Industrial Applications for UV LED Conveyors

The versatility of conveyorized systems makes them indispensable across several high-precision industries.

Electronics Manufacturing (PCBs)

PCB assembly requires the protection of sensitive components. UV LED conveyors are used for curing conformal coatings and encapsulants. The low heat output prevents damage to microchips, while the consistent belt speed ensures an even cure across the board.

Medical Device Assembly

Manufacturing catheters, syringes, and hearing aids requires biocompatible bonding. UV LED systems provide the process stability needed for validation, ensuring that medical-grade adhesives cure fully without thermal degradation.

Industrial Printing & Packaging

From labeling bottles to coding packaging, speed is the priority. LED systems can cure inks instantly at high conveyor speeds, allowing products to be packed immediately without smear risks.

Powder Coating

While traditional ovens are common, UV-cured powder coatings are gaining traction for heat-sensitive substrates like wood or MDF. To understand how line design impacts this process, see our article on UV LED Curing Systems for Powder Coating: Line Design Basics.

Critical Selection Factors: How to Choose the Right System

Selecting a conveyor isn't just about belt size; it's about matching the physics of light to chemistry.

1. Match the Wavelength (The Golden Rule)

Your UV adhesive or ink is formulated to react to a specific wavelength. Using the wrong light source will result in a failed cure.

- 365nm: Ideal for deep curing adhesives and thicker layers.

- 395nm / 405nm: Common for surface curing, inks, and thin coatings.

- Tip: Always check the Technical Data Sheet (TDS) of your material before buying the machine.

2. Determine Required Irradiance vs. Energy Density

- Irradiance (W/cm²): The intensity of the light. High irradiance is needed to penetrate deep or pigmented materials.

- Energy Density (mJ/cm²): The total amount of light over time (Intensity × Time). This is controlled by the conveyor speed.

3. System Format: Spot, Area, or Conveyor?

Do you need a conveyor? If you are processing continuous sheets or high volumes of small parts, a conveyor is best. However, for stationary batch processing, a static area lamp might suffice. Compare the options in our detailed breakdown: UV LED Curing Systems for Coating: Area vs Conveyor.

4. Belt Width and Speed Range

Ensure the belt is 20-30% wider than your largest part to avoid edge effects. The speed range must accommodate your required cure time; if your material needs 5 seconds of exposure but the belt moves too fast, you will need a longer conveyor or multiple LED heads.

Common Mistakes to Avoid When Switching to LED

Transitioning from mercury to LED often fails due to these overlooked factors:

- Oxygen Inhibition: Oxygen in the air can interfere with the curing reaction on the very surface of the resin, leaving it tacky or sticky. Solution: Use higher intensity LED heads (395nm often helps) or nitrogen-inerted conveyor tunnels.

- Mismatched Chemistry: Using "dual-cure" or mercury-optimized formulations with an LED source. Solution: Ensure your supplier confirms the material is "LED-formulated."

- Shadowing: On complex 3D parts, the light might not reach undercuts or sides. Solution: Use angled LED heads or mirrors within the conveyor tunnel to bounce light onto all surfaces.

Maintenance and Lifespan Expectation

One of the strongest arguments for UV LED is the low maintenance requirement. A typical LED array can last over 20,000 hours, compared to just 1,000 hours for a mercury bulb.

Routine Maintenance Checklist:

- Clean the Quartz Window: Dust or adhesive splatter on the glass window blocks UV light. Clean weekly with isopropyl alcohol.

- Check Belt Tracking: Ensure the belt isn't drifting to one side, which damages the edges.

- Inspect Cooling Intake: For air-cooled systems, keep filters clean to prevent overheating the LED chips.

- Radiometer Verification: Use a UV radiometer monthly to measure output and ensure the LEDs haven't degraded.

Frequently Asked Questions (FAQ)

What is the difference between UV and UV LED curing?

Traditional UV curing uses mercury vapor bulbs that emit a broad spectrum of light and high heat. UV LED curing uses semiconductors to emit a single, narrow wavelength of UV light, resulting in a cooler, more energy-efficient process with instant on/off capabilities.

How long do UV LED curing lights last?

High-quality UV LED arrays typically last between 20,000 and 30,000 hours of operation. Since they are only turned on when a product is present (instant on/off), the actual service life in years is often much longer than mercury bulbs which must stay on all day.

What materials can be cured with UV LED?

You can cure UV-formulated adhesives, potting compounds, conformal coatings, and inks. However, the material must be specifically formulated for LED wavelengths (usually 365nm, 385nm, 395nm, or 405nm) to cure properly.

Do UV LED lights get hot?

The light beam itself is "cool" and contains minimal infrared heat, protecting the product. However, the LED chips inside the head do generate heat and require air or water cooling to function efficiently.

Can I retrofit my old conveyor with LED heads?

Yes, in most cases. You can remove the old mercury lamp housing and mount new UV LED heads onto your existing conveyor frame. This is a cost-effective way to upgrade to LED technology without replacing the entire handling system.

How do I calculate UV curing dose?

Dose (Energy Density) is calculated as Irradiance (W/cm²) × Time (seconds). On a conveyor, "Time" is determined by the belt speed and the length of the curing area. You verify this using a UV radiometer designed for LED sources ("puck" style).

Is UV LED curing safe for operators?

While safer than mercury (no ozone, no glass bulbs), UV LED light is still high-intensity radiation that can damage eyes and skin. Operators must always wear UV-blocking safety glasses and ensure all light shields on the conveyor are intact.

Conclusion

Switching to a UV LED conveyor curing system is one of the most effective upgrades a manufacturing facility can make in 2026. Whether you are bonding medical devices or coating electronics, the move from thermal-heavy mercury lamps to cool, efficient LEDs offers immediate ROI through energy savings and reduced scrap.

However, success depends on matching the wavelength to your material and sizing the machine correctly.

Ready to optimize your production line?

Contact the UVET engineering team today. We can help you determine the exact wavelength, irradiance, and conveyor speed required for your specific application—ensuring a perfect cure every time.