UV LED Curing Systems for Powder Coating: Line Design Basics

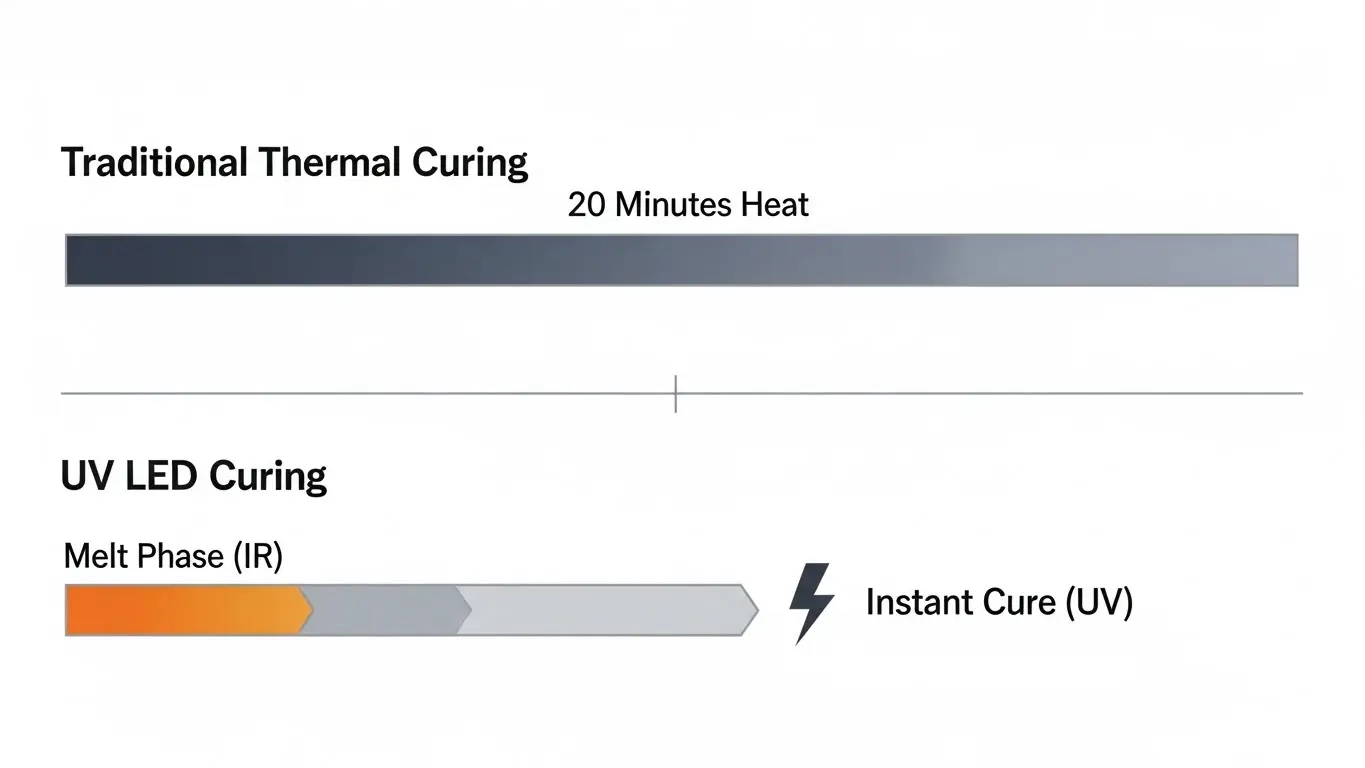

UV LED curing systems for powder coating utilize a two-step "melt and cure" process that separates the flowing of the powder from the actual cross-linking. Unlike traditional thermal powder coating which requires 15-30 minutes of high heat to both melt and cure, a UV LED line uses a short infrared (IR) or convection cycle to melt the powder (1–2 minutes) followed by a split-second exposure to high-intensity UV LED light to cure it instantly. This separation allows for lower operating temperatures, significantly smaller equipment footprints, and the ability to coat heat-sensitive materials like MDF, plastic, and assembled components without thermal damage.

How UV LED Powder Coating Works: The "Melt vs. Cure" Concept

To design an effective line, you must first understand that UV LED lamps alone cannot process standard powder coating. The process relies on distinct phases.

- The Melt Phase (Thermal): The powder particles must flow together to form a smooth, continuous film. This requires heat, but significantly less heat than traditional methods.

- The Cure Phase (Photopolymerization): Once molten, the film is exposed to UV LED light. Photoinitiators in the powder absorb this energy and instantly cross-link the polymer chains.

This separation is the defining advantage. By limiting heat only to the "melt" phase, you avoid the long soak times required for thermal curing.

Designing the UV LED Curing Line

A typical UV LED powder coating line requires less than half the floor space of a conventional thermal line. Below are the essential components of a functional layout.

The Pre-Heat / Melt Station (IR or Convection)

Before the UV station, the part passes through a melt zone.

- Technology: Medium-wave Infrared (IR) emitters or gas convection ovens are standard.

- Temperature: The goal is to reach the powder's melt point (typically 100°C - 130°C) without overheating the substrate.

- Duration: Parts typically reside here for only 1 to 2 minutes, just long enough for the powder to flow out and level.

The UV LED Curing Station

This is where the magic happens. As the part exits the melt zone, it immediately enters the UV curing zone.

- Lamp Positioning: Lamps must be positioned to ensure "line of sight" to all coated surfaces. For complex 3D parts, this often requires a multi-angle arrangement (top, bottom, and sides).

- Wavelength Matching: The UV LED output (commonly 365nm, 385nm, or 395nm) must match the photoinitiator absorption profile in the powder formulation.

- Irradiance: High peak irradiance is critical to penetrate the opaque powder coating and ensure full adhesion to the substrate.

For a deeper dive on selecting the correct specific output for your line, read our guide on UV LED Coating Curing: Choosing the Right Lamp.

Conveyance and Cooling

Because the parts are processed at lower temperatures (roughly 110°C vs. 200°C+ for thermal), the cool-down zone is minimal.

- Line Speed: UV LED systems can often run faster than thermal lines because the curing bottleneck is removed.

- Conveyor Style: Line stability is crucial. Vibrations during the melt phase can disturb the powder flow before it cures.

For more on line configurations, refer to UV LED Curing Systems for Coating: Area vs Conveyor.

Can you powder coat heat-sensitive materials with UV LED?

Yes, UV LED systems are specifically ideal for heat-sensitive substrates.

Because the process separates melting from curing, the substrate is not exposed to high heat for long periods. The core of the material (like wood or plastic) stays relatively cool while only the surface reaches the melt temperature. This prevents warping, outgassing, or degradation, making it the standard for coating Medium Density Fiberboard (MDF), thermoplastics, and even pre-assembled electronic components.

Learn more about the protocols for these materials in our article on UV LED Curing for Heat-Sensitive Substrates: Best Practices.

What is the difference between thermal and UV powder coating?

The main difference is the curing mechanism: Time/Temperature vs. Light Energy.

- Thermal Curing: Relies on holding the part at high temperatures (approx. 200°C) for 20+ minutes to drive the chemical reaction.

- UV Curing: Uses chemical photoinitiators that react instantly to light. Heat is only used briefly to melt the powder.

This difference results in a process that is 80-90% faster and consumes significantly less energy.

How much energy does a UV LED powder line save?

UV LED powder lines typically reduce energy consumption by 40% to 60% compared to thermal lines.

Savings come from three areas:

- Elimination of large ovens: You no longer need to keep a massive thermal mass hot all day.

- Instant On/Off: UV LED lamps utilize "instant-on" technology. They are only powered when a part is directly in front of them, unlike arc lamps or thermal ovens that run continuously.

- Reduced HVAC load: Less waste heat creates a cooler plant environment, lowering air conditioning costs.

General principles of energy efficiency in these setups are covered in UV LED Curing for Coatings.

Comparison: Thermal vs. Arc UV vs. UV LED

| Feature | Thermal Powder Coating | UV Arc (Mercury) Powder Coating | UV LED Powder Coating |

| Cure Mechanism | Heat (long dwell) | Broad Spectrum UV Light | Narrow Spectrum UV Light |

| Total Process Time | 20 - 40 Minutes | 2 - 5 Minutes | 2 - 3 Minutes |

| Substrate Temp | > 200°C | ~100°C - 120°C | ~80°C - 110°C |

| Substrate Suitability | Metal Only | Metal, some Wood | Metal, Wood, Plastic, Composites |

| Energy Efficiency | Low | Medium | High |

| Equipment Footprint | Large (Long Ovens) | Medium | Compact |

Frequently Asked Questions

Do I need special powder for UV LED lines?

Yes. You cannot use standard thermal powder. You must use "UV-curable powder coatings" which contain photoinitiators formulated to react to specific UV wavelengths.

Is UV powder coating as durable as thermal?

Yes. When properly cured, UV powder coatings exhibit excellent scratch resistance, hardness, and chemical resistance, often exceeding thermal counterparts in hardness due to higher cross-link density.

Can I retrofit my existing powder line?

Often, yes. You can retain your spray booth and washing station. The retrofit involves replacing the long thermal cure oven with a shorter IR melt oven and a compact UV LED curing station.

What is the "shadowing" issue in line design?

UV curing is "line-of-sight." If a complex part has hidden crevices that the light cannot reach, those areas will not cure. Line design must use multi-angle lamps or rotating hangers to ensure 360-degree exposure.

Key Takeaways

- Dual Process: UV powder coating separates the "melt" (IR heat) from the "cure" (UV light).

- Heat Sensitivity: The low-temperature process enables powder coating on wood (MDF), plastic, and composites.

- Compact Design: Lines are significantly shorter than thermal lines because they eliminate massive cure ovens.

- Lamp Selection: Success depends on matching the LED wavelength (e.g., 395nm) to the powder's photoinitiator.

Conclusion

Designing a UV LED curing line for powder coating requires a shift in thinking from "heat soak" to "energy precision." By leveraging the separation of melt and cure, manufacturers can dramatically increase throughput, lower energy bills, and unlock new material possibilities.

If you are evaluating a switch to UV LED powder coating, start by auditing your substrate mix and available floor space.