What Is UV LED Ink Curing? The Complete Printer's Guide

Traditional ink drying wastes hours of production time—and money. Every minute your prints sit waiting to dry is a minute you're not fulfilling orders.

If you've ever dealt with smudged prints, slow turnaround times, or excessive energy bills from heat-based drying systems, you're not alone. These frustrations push print shops to seek faster, more efficient alternatives.

That's where UV LED ink curing comes in. This technology transforms liquid ink into a solid, durable finish in seconds—not hours—using specialized ultraviolet light.

In this guide, I'll break down exactly how UV LED curing works, why it's becoming the industry standard, and whether it's the right investment for your printing operation.

What you will learn

- What UV LED ink curing is and how the photochemical process works

- The key differences between UV LED and traditional mercury lamp curing

- 5 major benefits that make printers switch to UV LED technology

- Which printing applications benefit most from UV LED curing

- Best practices for implementing UV LED systems in your workflow

What is UV LED ink curing?

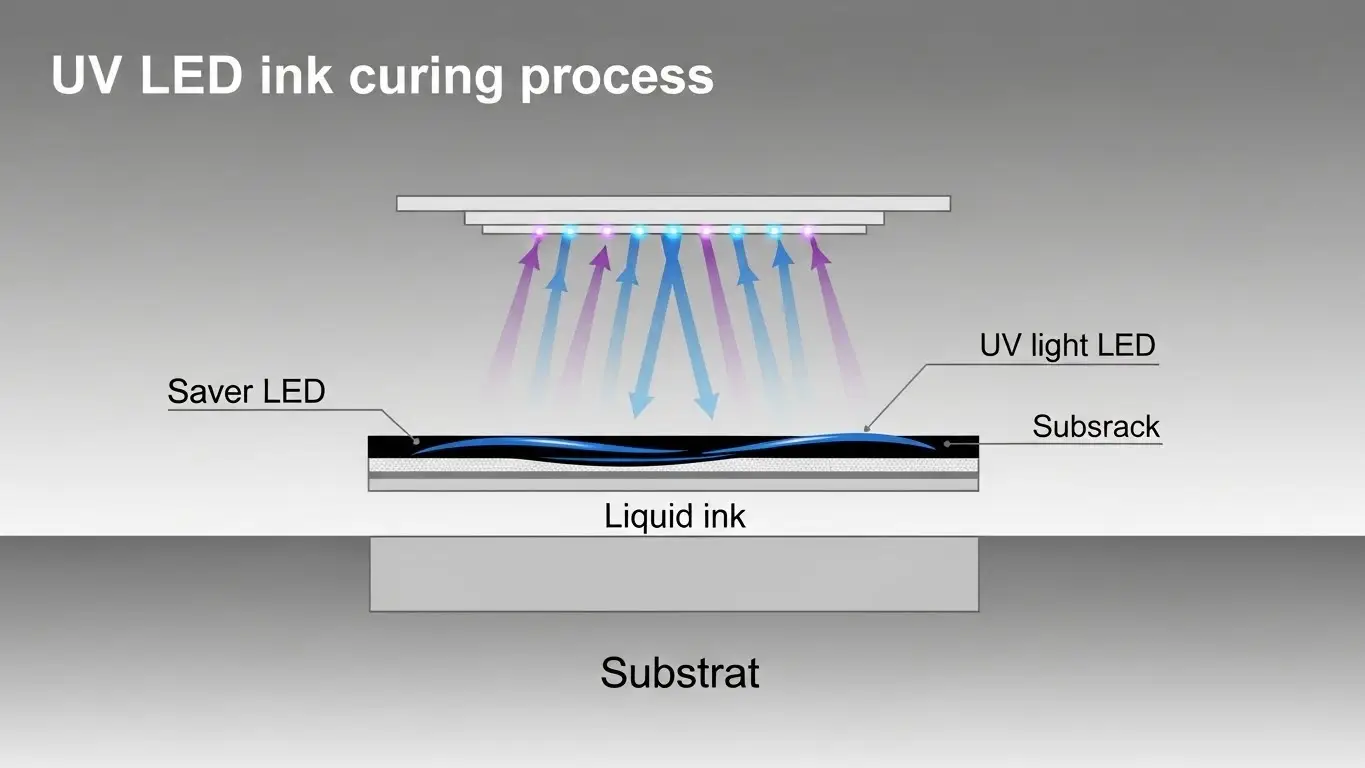

UV LED ink curing is a photochemical process that uses ultraviolet light-emitting diodes (LEDs) to instantly harden specially formulated inks, coatings, and adhesives. Instead of waiting for solvents to evaporate like traditional drying methods, UV LED curing triggers an immediate chemical reaction that transforms liquid ink into a solid polymer.

Here's how it works: UV LED inks contain photoinitiators—chemical compounds that absorb ultraviolet light at specific wavelengths (typically 365-405nm). When exposed to UV LED light, these photoinitiators generate free radicals that cause the ink's monomers and oligomers to cross-link and polymerize. The result? A fully cured, touch-dry surface in less than a second.

Think of it like instant superglue activation. The UV light acts as a trigger, starting a chain reaction that locks the ink molecules together permanently. No heat required. No drying time. No waiting.

This technology has revolutionized printing across industries. According to Smithers research, the global UV curing market is projected to reach $7.5 billion by 2027, driven largely by demand for faster production and sustainable printing solutions.

Why does UV LED ink curing matter?

Traditional printing methods come with significant drawbacks: long drying times, high energy consumption, and material limitations. UV LED curing addresses these pain points directly.

1. Dramatically faster production speeds

Speed changes everything in commercial printing.

Traditional solvent-based inks can take minutes to hours to fully dry, depending on substrate and environmental conditions. UV LED curing happens in milliseconds.

This instant cure allows for:

- Immediate stacking and finishing without risk of smearing

- Higher press speeds since you're not waiting for drying

- Same-day turnaround on time-sensitive projects

- Reduced work-in-progress inventory on your production floor

For high-volume operations, this speed advantage translates directly to increased capacity without additional equipment.

2. Lower energy consumption and operating costs

Here's a number that gets CFOs' attention: UV LED systems use up to 70% less energy than traditional mercury arc lamp curing systems.

Why the dramatic difference?

Mercury lamps generate enormous amounts of heat—energy that's essentially wasted. They also require warm-up and cool-down periods, meaning they consume power even when not actively curing. UV LEDs, by contrast, operate at much lower temperatures and switch on/off instantly.

The savings compound over time:

- No warm-up cycles means immediate operation

- Reduced HVAC costs from lower heat output

- Longer operational lifespan (20,000-30,000 hours vs. 1,000-2,000 for mercury lamps)

- No bulb replacement costs during typical equipment lifetime

3. Print on heat-sensitive materials

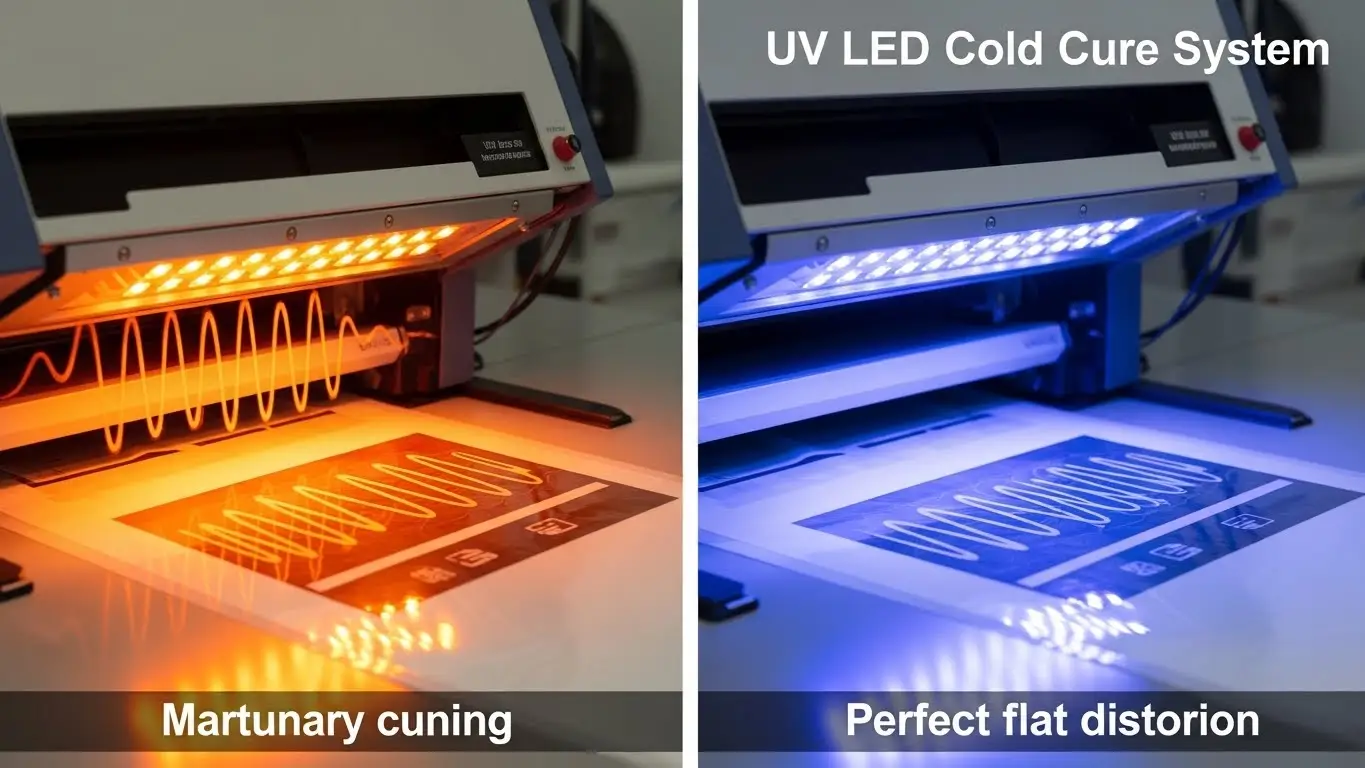

Traditional UV curing generates significant infrared heat—enough to warp thin plastics, shrink films, and damage heat-sensitive substrates. This limits your material options.

UV LED curing operates as a "cold cure" process. The light output contains minimal infrared radiation, keeping substrate temperatures significantly lower.

This opens the door to printing on:

- Thin polyethylene and polypropylene films

- Stretch films and shrink sleeves

- Heat-sensitive plastics like PVC and PETG

- Pre-printed materials that would otherwise distort

- Electronics and flexible circuits

For packaging printers especially, this material flexibility is a game-changer.

4. Superior print durability and quality

UV LED-cured inks don't just dry faster—they perform better.

The cross-linked polymer structure created during curing produces prints with:

- Excellent scratch and abrasion resistance

- Superior chemical resistance to solvents and cleaning agents

- Enhanced color vibrancy with higher gloss retention

- Better outdoor durability for signage applications

- Improved adhesion to challenging substrates

These performance characteristics make UV LED curing ideal for applications where print durability matters: labels, packaging, outdoor signage, and industrial marking.

5. Environmental and safety advantages

Mercury arc lamps contain hazardous materials and produce ozone—a respiratory irritant that requires ventilation systems to manage safely.

UV LED systems eliminate these concerns:

- No mercury means no hazardous waste disposal requirements

- No ozone production reduces ventilation needs

- Lower VOC emissions compared to solvent-based inks

- Reduced carbon footprint from energy efficiency gains

For printers pursuing sustainability certifications or responding to customer environmental requirements, UV LED technology provides measurable improvements.

How UV LED curing compares to traditional methods

Understanding the differences helps you evaluate whether switching makes sense for your operation.

| Feature | UV LED Curing | Mercury Arc Lamp Curing | Solvent-Based Drying |

|---|---|---|---|

| Cure time | Milliseconds | Seconds | Minutes to hours |

| Energy use | Low | High | Moderate |

| Heat output | Minimal (cold cure) | Significant | Variable |

| Lamp life | 20,000+ hours | 1,000-2,000 hours | N/A |

| Warm-up time | Instant on/off | 5-15 minutes | N/A |

| Ozone production | None | Yes (requires ventilation) | None |

| Mercury content | None | Contains mercury | None |

| Material compatibility | Excellent (heat-sensitive OK) | Limited by heat | Good |

The bottom line? UV LED offers superior performance across nearly every metric that matters for modern print production.

Best practices for UV LED ink curing

Getting the most from UV LED technology requires attention to a few key factors.

Match your ink formulation to your LED wavelength

Not all UV inks are created equal. UV LED curing requires inks specifically formulated with photoinitiators that respond to LED wavelengths (typically 365nm, 385nm, 395nm, or 405nm).

Critical point: Using traditional UV inks with LED curing systems will result in incomplete curing. Always verify ink-LED compatibility with your supplier.

Optimize your curing distance and exposure

The intensity of UV light decreases rapidly with distance. Position your LED heads according to manufacturer specifications—typically 2-10mm from the substrate surface.

Key variables to dial in:

- Irradiance level (measured in mW/cm²)

- Exposure time/belt speed balance

- Peak wavelength for your specific ink formulation

Control your environment

While UV LED curing is more forgiving than traditional methods, environmental factors still matter:

- Substrate temperature affects ink viscosity and flow

- Humidity levels can impact adhesion on certain materials

- Ambient light typically doesn't affect curing, but store inks away from UV exposure

Plan for proper maintenance

UV LED systems require less maintenance than mercury lamps, but they're not maintenance-free:

- Keep LED arrays clean from ink mist and debris

- Monitor output intensity over time with a radiometer

- Check cooling systems (fans, heat sinks) regularly

- Inspect reflectors if your system uses them

Key takeaways

- UV LED ink curing is a photochemical process that uses ultraviolet LEDs to instantly polymerize specially formulated inks

- Instant curing in milliseconds eliminates drying wait times and enables immediate finishing

- Energy savings of up to 70% compared to traditional mercury lamp systems reduce operating costs significantly

- Cold cure technology allows printing on heat-sensitive materials like thin films and plastics

- Superior durability with enhanced scratch, chemical, and abrasion resistance outperforms traditional methods

- Environmental benefits include no mercury, no ozone production, and lower VOC emissions

- LED lamp life of 20,000+ hours eliminates frequent bulb replacements common with mercury systems

- Proper ink-LED matching is essential—traditional UV inks won't cure properly under LED systems

- Growing market adoption reflects the technology's proven advantages for modern printing operations

FAQ

Is UV LED curing more expensive than traditional UV curing?

The initial investment for UV LED systems is typically higher than mercury arc lamp alternatives. However, the total cost of ownership favors UV LED due to dramatically lower energy consumption, no lamp replacement costs, and reduced maintenance requirements. Most operations see ROI within 2-3 years through operational savings.

Can I use regular UV inks with UV LED curing systems?

No. Traditional UV inks are formulated for the broad-spectrum output of mercury lamps, while UV LED systems emit specific narrow wavelengths. You must use inks specifically formulated for UV LED curing with photoinitiators matched to your system's wavelength output.

What materials can be printed with UV LED curing?

UV LED's low-heat "cold cure" process works on virtually any printable substrate, including heat-sensitive materials that traditional UV curing would damage. Common applications include paper, cardboard, rigid plastics, thin films, metal, glass, wood, and specialty substrates like pre-printed materials and flexible electronics.

How long do UV LED lamps last?

UV LED arrays typically last 20,000 to 30,000 operating hours—roughly 10-20 times longer than mercury arc lamps. This extended lifespan, combined with instant on/off operation (no warm-up degradation), means most UV LED systems never require lamp replacement during their service life.

Is UV LED-cured ink safe for food packaging?

UV LED inks can be formulated for low-migration food packaging applications when proper compliance-grade formulations are used. Look for inks that meet FDA, Swiss Ordinance, or Nestlé guidance requirements. Always verify specific ink certifications with your supplier for food-contact applications.

Conclusion

UV LED ink curing represents a significant leap forward in printing technology. Faster production, lower costs, expanded material options, and environmental benefits make it an increasingly essential capability for competitive print operations.

The technology has matured to the point where it's no longer a question of if you should consider UV LED—but when it makes sense for your specific production needs.

Ready to explore UV LED solutions for your operation? Start by evaluating your current energy costs, production bottlenecks, and material limitations—these pain points often reveal where UV LED technology delivers the fastest return.