What Wavelength Is Best for Flexo UV Inks?

For most flexographic printing applications, 395 nm (nanometers) is the best and most widely used wavelength for UV LED inks. This wavelength offers the optimal balance between cure speed, depth of cure (penetration), and energy efficiency.

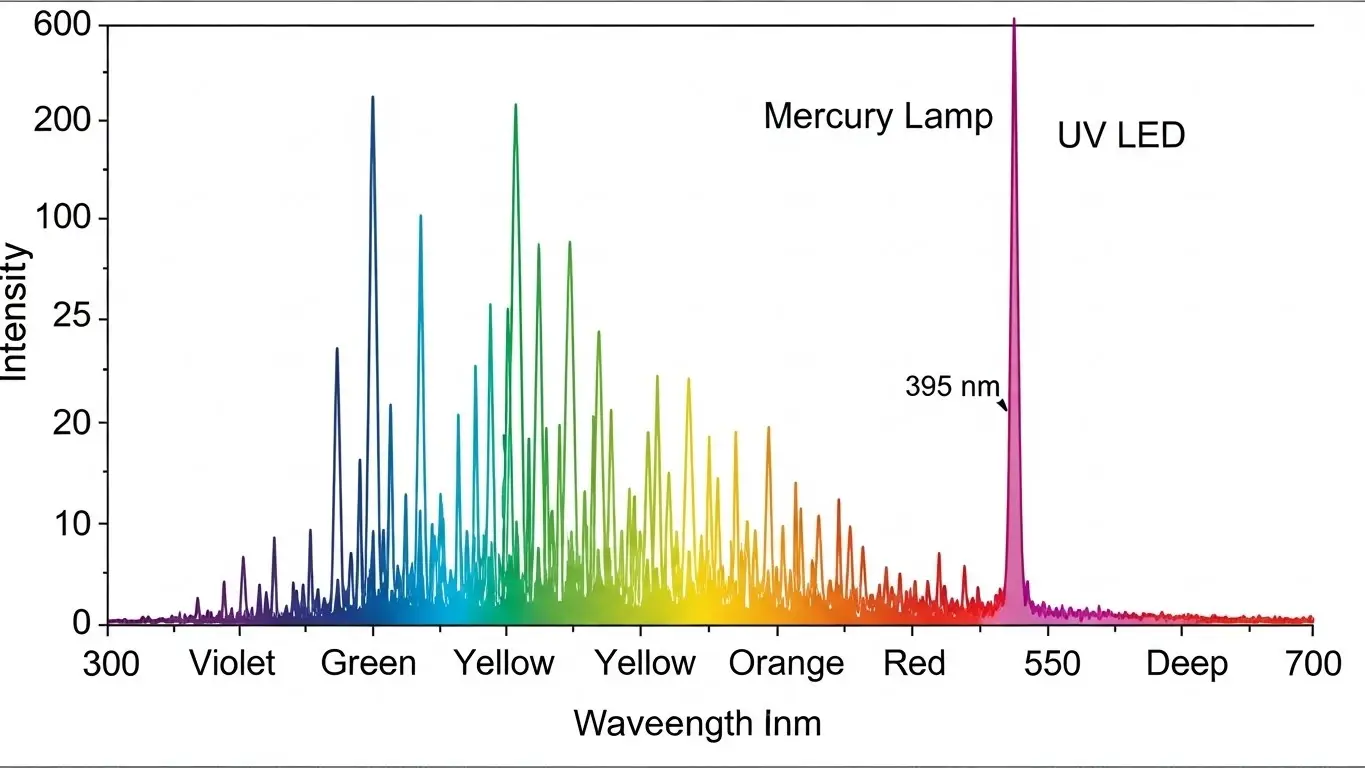

While traditional mercury vapor lamps emit a broad spectrum of light, modern UV LED systems focus on specific narrow peaks. The 395 nm wavelength is the industry standard because it effectively penetrates thicker ink layers—including difficult-to-cure opaque whites, blacks, and metallics—ensuring the ink adheres firmly to the substrate rather than just drying on the surface.

Understanding UV Wavelengths in Flexo Printing

In the shift from conventional mercury arc lamps to UV LED technology, understanding wavelength is critical for print quality and press speed. Unlike mercury lamps that blast a chaotic mix of UV-A, UV-B, and UV-C, UV LED curing systems emit precise, monochromatic bands of energy.

Why 395 nm Dominates the Industry

The 395 nm wavelength has become the "sweet spot" for flexo label and packaging printers for several reasons:

- Deep Penetration (Through-Cure): Longer wavelengths (like 395 nm) penetrate deeper into the ink film than shorter wavelengths. This is essential for flexo, where heavy ink laydowns are common.

- Pigment Compatibility: Dark pigments (like carbon black) and reflective pigments (like titanium dioxide in white ink) block shorter UV waves. The 395 nm wavelength can bypass these obstacles to cure the ink all the way to the base material.

- Cost and Availability: Due to high demand, 395 nm LED chips are mass-produced, making them more affordable and powerful than other UV LED options.

To learn more about how this technology integrates with your press, read about UV LED Curing for Flexo & Labels.

395 nm vs. 385 nm vs. 365 nm: What’s the Difference?

While 395 nm is the standard, you may encounter other wavelengths. Here is how they compare in a flexo environment:

1. 395 nm (The Standard)

- Best For: General flexo printing, labels, opaque whites, and high-speed production.

- Pros: Excellent through-cure (adhesion), lower cost, high intensity.

- Cons: Slightly less surface cure hardness compared to shorter wavelengths (though modern nitrogen inerting solves this).

2. 385 nm (The Hybrid)

- Best For: Specific varnishes or clear coatings where surface cure is slightly more critical than depth.

- Pros: A middle ground between surface and deep curing.

- Cons: Often more expensive than 395 nm systems with marginal performance gains for standard inks.

3. 365 nm (The Specialist)

- Best For: Very specific adhesives or ultra-thin coatings.

- Pros: excellent for surface curing and preventing "oxygen inhibition" (tackiness).

- Cons: Poor penetration through thick/dark inks; significantly higher equipment cost.

Comparison of UV LED Wavelengths for Flexo

| Feature | 395 nm (Recommended) | 385 nm | 365 nm |

| Primary Use | Flexo Inks (Blacks/Whites) | Varnishes / Coatings | Laminating Adhesives |

| Cure Depth | Deep (Through-Cure) | Medium | Shallow (Surface Cure) |

| Energy Output | Very High | High | Moderate |

| Cost | Lowest | Medium | Highest |

Can I Use Standard UV Ink with LED Lamps?

No, you cannot use standard UV inks with LED lamps. Standard UV inks are formulated to react to the broad spectrum of light emitted by mercury lamps (UV-A, B, and C).

UV LED inks contain specific photoinitiators designed to react exclusively to the narrow 395 nm (or 385 nm) band. If you try to cure standard ink with an LED lamp, it will likely remain wet or tacky because the photoinitiators won't trigger the polymerization process.

For a deeper dive into the transition between technologies, check out our guide on What Is LED UV Curing in Flexo Printing?.

How Does Wavelength Affect Ink Adhesion?

Adhesion is the result of a successful "through-cure." If the UV light cannot reach the bottom of the ink layer (where it touches the label material), the ink will scuff off easily.

- Short Wavelengths (200-280 nm): Great for surface sealing but get blocked by pigments.

- Long Wavelengths (395 nm): Act like a spear, piercing through the pigment to cure the ink at the adhesion point.

This is particularly important when selecting the Best UV LED Curing System for Flexo Label Printing, as the system must match your ink's specific requirements to prevent delamination.

Does Wavelength Impact Odor in Food Packaging?

Yes, wavelength and curing efficiency play a massive role in low-migration and low-odor printing. If an ink is under-cured because the wavelength didn't penetrate deep enough, uncured monomers remain trapped in the ink film.

These uncured chemicals can migrate into food packaging or cause a strong, unpleasant smell. Using a high-intensity 395 nm system ensures a complete cure, locking the chemicals into a solid polymer chain. This is a critical step if you want to How to Reduce Odor in UV Flexo Inks with LED Curing.

Frequently Asked Questions

What happens if I use the wrong wavelength?

Using the wrong wavelength (e.g., a 365 nm lamp on an ink designed for 395 nm) will result in "surface skinning." The top of the ink will dry, but the middle will remain liquid, leading to poor adhesion and ink peeling off the substrate.

Is 395 nm light safe for operators?

While 395 nm is just on the edge of visible violet light, it is still high-intensity UV radiation. It is safer than the harmful UV-C generated by mercury lamps (no ozone is produced), but operators must still wear UV-protective eyewear and cover exposed skin.

Can I mix 395 nm and 385 nm lamps on one press?

Yes, some advanced "hybrid" presses use varying wavelengths. For example, a printer might use 395 nm for the base colors (CMYK) to ensure good adhesion and a 385 nm or 365 nm lamp for the final varnish to ensure a hard, scratch-resistant surface.

Do white inks require a specific wavelength?

Yes. White ink contains Titanium Dioxide (TiO2), which is highly reflective. 395 nm is essential for white ink because it is one of the few UV wavelengths that can penetrate TiO2 effectively to cure the layer completely.

Key Takeaways

- 395 nm is the standard wavelength for UV LED flexo printing due to its superior ability to penetrate thick and pigmented inks.

- Don't mix inks: You must use inks specifically formulated for LED wavelengths; standard mercury UV inks will not cure properly.

- Better Adhesion: Longer wavelengths like 395 nm ensure "through-cure," bonding the ink firmly to the substrate.

- Safety & Odor: Proper wavelength selection reduces uncured monomers, leading to lower odor and safer packaging.

Conclusion

Choosing the right wavelength is not just a technical detail—it is the difference between a high-quality label and a rejected print job. For the vast majority of flexo applications, 395 nm offers the perfect combination of power, penetration, and performance.

If you are ready to upgrade your press or need help matching your curing system to your specific ink formulations, contact us today to discuss the optimal setup for your production line.