What Are the Limitations of UV LED Curing?

Evaluating the constraints of any industrial technology is essential for ensuring process reliability. While UV LED curing limitations have decreased as the technology matures, certain spectral and operational boundaries remain. This guide examines where UV LED systems may face challenges, specifically regarding material chemistry, layer thickness, and environmental factors. By identifying these limitations, you can make more informed decisions about equipment selection and process design for your production facility.

What Are the Common Limitations of UV LED Curing Technology?

UV LED curing technology, like any technology, has limitations that can affect material compatibility, depth of cure, spectral breadth, and process fit in some situations. You will find that these systems operate within a narrow wavelength band, which can restrict their ability to cure coatings designed for broad-spectrum mercury lamps. Additionally, while LED arrays are highly efficient, the absence of short-wave UVC radiation can sometimes result in surface tackiness or incomplete bonding in specific chemical formulations.

Recognizing these constraints is not a reason to avoid the technology but rather a requirement for proper implementation. You must evaluate how your specific inks and adhesives respond to a single-peak light source. In cases where materials require multiple wavelengths to cure through different depths, a standard LED setup may need to be modified or paired with reformulated chemistry to meet your quality standards.

How Does Spectral Output Affect Materials That Are Hard to Cure?

Spectral output limitations can affect materials that require wavelengths outside typical UV LED ranges, such as those relying on UVC energy for surface hardening. You may find that certain clear coats or high-gloss finishes stay slightly tacky because the LED wavelength (typically 365nm to 395nm) does not trigger the surface-level photoinitiators. This mismatch between the light source and the chemical recipe can lead to finish defects or reduced scratch resistance.

- Photoinitiator Selection: Your materials must be specifically tuned to the narrow output of the LED.

- Surface Cure Issues: The lack of short wavelengths can hinder the oxygen inhibition work-around that mercury lamps provide.

- Wavelength Availability: If your material requires 250nm for a specific reaction, standard industrial LEDs cannot currently meet that need.

Where Can Depth of Cure and Penetration Be Challenging for UV LED?

Depth of cure and penetration can be challenging for UV LED when materials are thick, opaque, or highly filled with pigments. You will notice that while UV light is intense at the surface, its ability to travel through dense liquids is limited by the specific wavelength being used. If you are working with dark blacks, opaque whites, or heavy industrial resins, the UV energy may be absorbed at the top layer, leaving the material underneath in a liquid or semi-liquid state.

This challenge requires you to carefully balance your line speed and lamp intensity. In some cases, you might need to use a longer wavelength (like 395nm or 405nm) which generally penetrates deeper into materials than 365nm light. Proper testing is the only way to ensure that the bond reaches the substrate, preventing issues like delamination or "skinning" where only the top layer is hard.

What Operational Constraints Might Limit UV LED Use in Some Processes?

Operational constraints such as dwell time and line speed can limit how UV LED systems perform in some processes, especially those with very short exposure windows. You must ensure that the "dosage"—the total energy delivered over time—is sufficient to complete the chemical reaction at your desired conveyor speed. If your line moves too fast for the lamp's output capacity, the material will not receive enough energy to reach full structural strength.

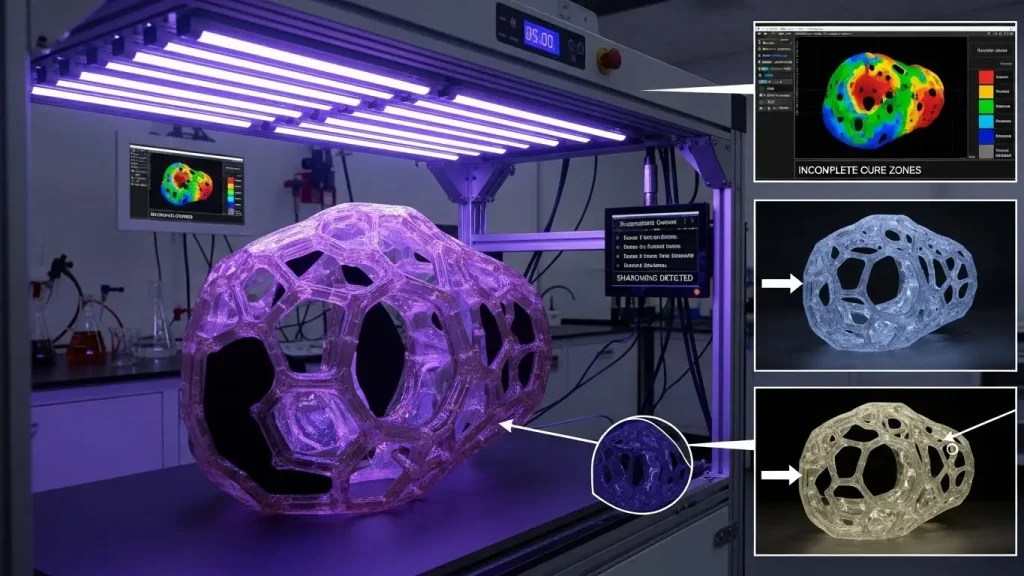

The physical mounting distance also plays a role. If your parts have deep recessed areas or complex 3D shapes, the directional nature of LED light can create shadows. Unlike mercury lamps that use large reflectors to bounce light from many angles, LEDs point straight down. You may need more lamp heads or custom mounting fixtures to ensure the light reaches every hidden surface of your part during the curing cycle.

How Do Environmental Factors Influence UV LED Curing Limits?

Environmental factors such as ambient temperature and airflow can influence UV LED curing performance by affecting the internal cooling of the lamp heads. You must maintain a stable operating temperature for the LED diodes to prevent their light output from dropping. If your factory floor is excessively hot or if the airflow around the cooling fins is blocked, the system may automatically dim itself to protect the electronics, resulting in an under-cured product.

Dust and contaminants in your environment can also settle on the LED lenses. Because LEDs stay relatively cool, they do not "burn off" dust like hot mercury bulbs do. You must implement a regular cleaning schedule to ensure that your light intensity stays consistent. Failure to manage these environmental variables can lead to drift in your process quality over time.

When Is Retrofit From Mercury UV to UV LED More Challenging?

Retrofiting existing mercury UV systems to UV LED can be challenging when process requirements push beyond typical LED limits, such as when using legacy chemistry. You may find that your current machines were designed for the heat and broad light of mercury, and simply swapping the lamp head is not enough. You might also need to replace your entire conveyor belt or update your material supply to ensure the new system works as intended.

The lack of infrared heat in LED systems can also be a hurdle for some retrofits. Some older coatings use the heat from mercury lamps to help the liquid flow and level out before it sets. When you remove that heat with an LED, the coating may look "textured" or uneven. You must evaluate the entire process, including the pre-heating steps and chemical formulations, to ensure a successful transition to the newer technology.

What Are the Key Takeaways on UV LED Curing Limitations?

Understanding the limitations of UV LED technology allows you to design a process that is reliable and repeatable. By focusing on material compatibility and proper system integration, you can work around these constraints to achieve high-quality results.

- Wavelength Matching: Ensure your photoinitiators are tuned to the specific LED output.

- Penetration Depth: Test thick or opaque materials for a full through-cure.

- Heat Management: Remember that LED lamps need stable ambient temperatures to stay at peak power.

- Shadowing: Plan your lamp placement to reach 3D surfaces and avoid dark zones.

- Reformulation: Be prepared to update your inks or coatings when moving away from mercury lamps.

How Do UV LED and Mercury UV Curing Technologies Differ in Spectral Output?

The core difference lies in the breadth of light provided. You can see a technical breakdown of these light profiles on our UV LED vs mercury UV curing page. This explains why certain materials respond differently to each light source.

What Challenges Arise When Retrofitting Mercury UV to UV LED Systems?

Planning an upgrade requires a look at both hardware and chemistry. You can find guidance on the common hurdles in our retrofit mercury to UV LED guide. This covers everything from power supply changes to material validation.

How Do LED and Traditional UV Curing Lamps Compare in Practical Operation?

To see how these limits play out on the shop floor, check our comparisons for choosing a UV or LED curing lamp and the differences in light characteristics. These resources help you match the equipment to your specific job constraints.

What Are Common Material Compatibility Challenges With UV LED?

Some resins are naturally "LED-blind" because they lack the specific chemicals needed to react to 395nm light. You should consult with your material supplier to find "dual-cure" or LED-specific versions of your current inks. This is the most effective way to overcome spectral limitations.

How Do Thickness and Opacity Affect UV LED Cure Depth?

Light is absorbed as it travels through a medium. For very thick or dark coatings, the UV energy may run out before it reaches the substrate. Using higher-intensity lamps or slower line speeds can sometimes help, but material testing is necessary to confirm a structural bond.

What Process Speed Constraints Are Typical for UV LED Curing?

Your production speed is directly tied to how much light energy you can deliver per square inch. If you increase your line speed, you must either increase your lamp power or add more lamp heads to maintain a consistent cure. Understanding this balance is vital for high-volume manufacturing.

How Does Ambient Temperature Influence UV LED Curing?

LEDs are sensitive to heat. If your cooling system cannot keep up with a hot factory environment, the lamp's lifespan and output will suffer. Ensuring proper airflow or using water-cooled units is the best way to maintain stability in difficult environments.

What Misconceptions Exist About UV LED Curing Capabilities?

A common myth is that UV LED can cure anything a mercury lamp can. In reality, the narrow spectrum means that some "traditional" materials will never cure under an LED, no matter how much power you apply. Always verify compatibility through testing rather than assuming a universal fit.

Final Thoughts

Finalizing your evaluation of UV LED technology requires a balance between acknowledging its constraints and leveraging its strengths. While spectral narrowness and penetration depth are real factors you must manage, they are often offset by the gains in energy efficiency and substrate safety. By approaching your process with a testing-first mindset, you can identify these limitations early and adjust your chemistry or equipment layout accordingly. The most successful UV LED installations are those where the limitations were understood and designed for from day one.