Is UV LED Curing Safe for Operators? Safety Basics and Best Practices

Workplace safety is your top responsibility when you manage any industrial production line. UV LED curing is a safe and reliable method for your manufacturing needs when you follow proper design and operation protocols. This guide covers the essential risks, the best practices for your team, and the built-in protections that keep your operators secure. You can expect to learn how to maintain a secure workspace while you employ this UV LED curing technology.

Why Does Safety Matter for Operators?

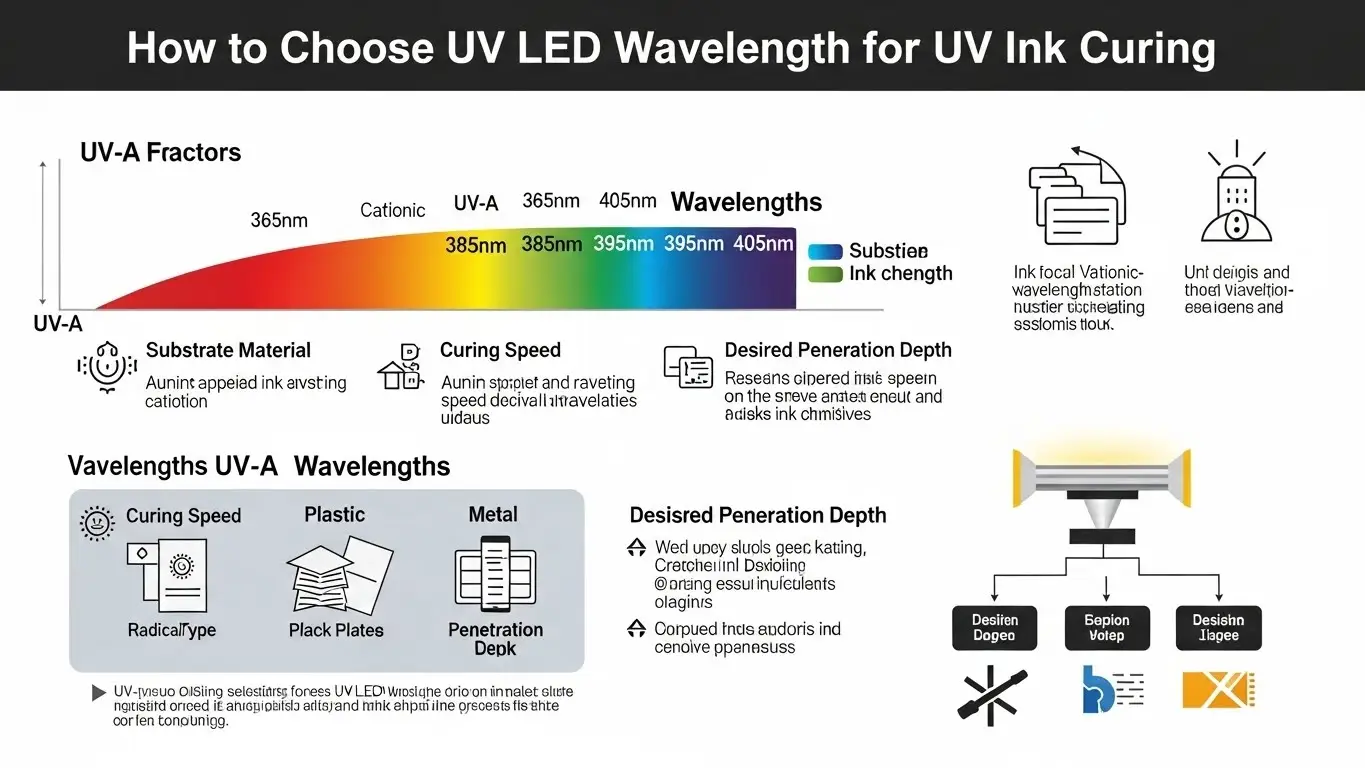

UV LED curing is a process that uses ultraviolet light to instantly harden inks, coatings, and adhesives. You must control your exposure to this light because the high-intensity energy can affect your eyes and skin if you lack proper protection. Safety matters because it prevents long-term health issues and ensures your production environment remains stable and compliant with industrial standards.

Your team needs to understand UV LED curing to work with it safely. The light used in these systems is concentrated into a narrow band. This concentration makes it very good at its job, but it also means the energy is strong. When you follow how UV LED curing works, you see that the light reacts with specific chemicals. Those same reactions can happen on your skin or in your eyes if the light is not contained. By respecting the power of the light, you protect yourself and your coworkers from accidental harm during your daily tasks.

Is UV LED Curing Inherently Safe Compared to Other Curing Methods?

UV LED curing is safer for you than many other industrial methods because it uses a controlled wavelength and produces very little heat. You do not have to worry about the high-pressure gases or toxic chemicals found in older lamp styles. While you still need to respect the UV light itself, the physical design of these systems removes many common shop hazards.

When you look at the UV LED curing benefits, safety is a major factor. These systems offer:

- No ozone production, so your air stays clean.

- No mercury, so you have no toxic spill risks.

- Low heat output, which reduces the chance of burns.

- Instant on and off, so the light is only active when you need it.

These features make the technology a safer choice for your shop floor. You get a tool that is easier to manage and less likely to cause a fire or a chemical emergency. As long as you keep the light inside its shields, your daily risk is very low.

What Are the Main Safety Risks Associated With UV LED Curing?

Safety risks exist in UV LED curing, but they are well understood and easy for you to manage. The primary concern is direct or reflected exposure to the UV light, which can cause painful eye inflammation or skin burns similar to a severe sunburn. You must also be aware of the cooling systems and electrical parts to avoid standard mechanical hazards.

You should watch for these specific risks:

- Eye Damage: Looking at the light can cause "welder's flash" or long-term vision problems.

- Skin Exposure: Direct light can cause skin redness, aging, or more serious long-term damage.

- Reflected Light: Shiny surfaces on your products or machines can bounce the light back at you.

- Heat build-up: While the light is cool, the lamp head itself can get warm if the cooling fans fail.

By identifying these points, you can take the right steps to stay safe. Most accidents happen when people bypass shields or forget their glasses. If you stay alert and follow your training, you can work around these machines for years without any problems.

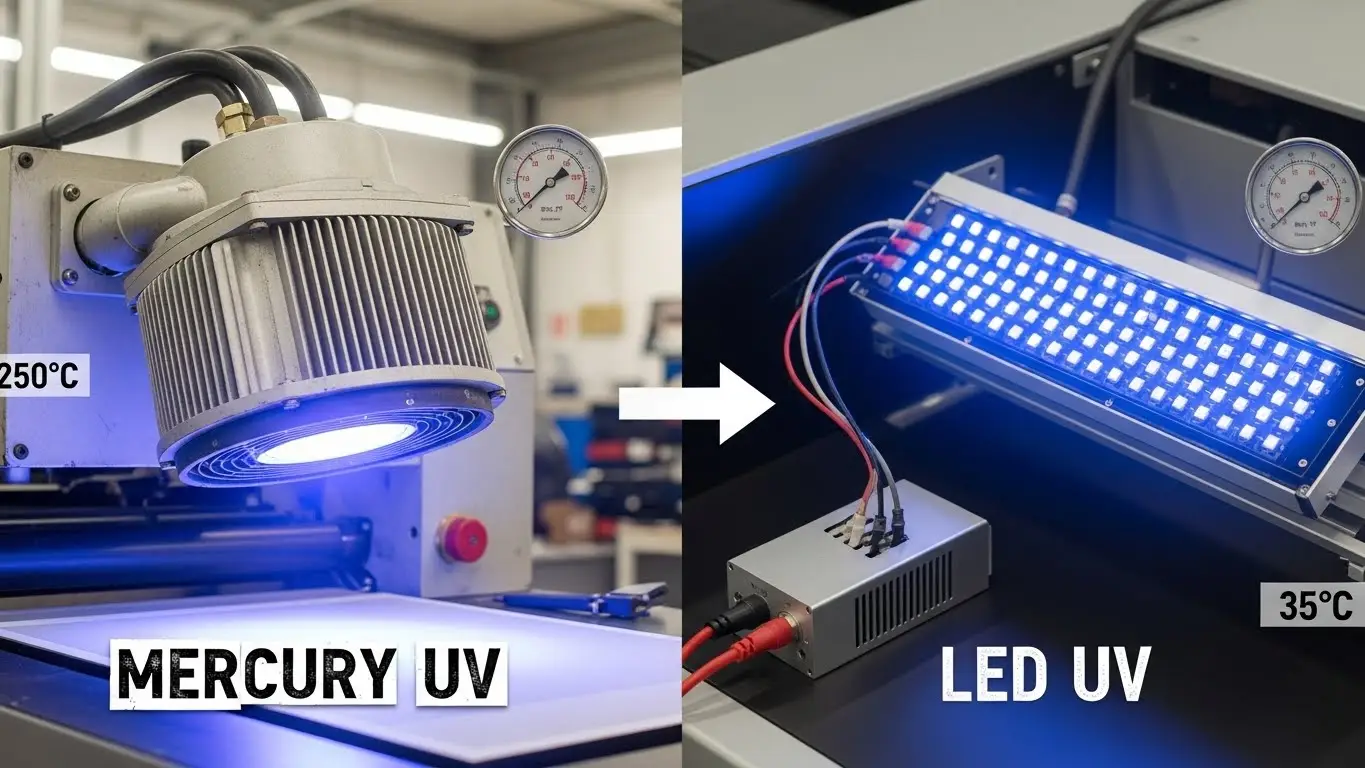

How Does UV LED Curing Compare to Mercury UV Curing in Terms of Safety?

UV LED curing is safer than mercury lamps because it removes the risk of toxic exposure and high-heat accidents. You no longer have to deal with mercury-filled bulbs that can shatter and release dangerous vapors into your work area. Plus, you eliminate the production of ozone, which can irritate your lungs and requires expensive air systems to remove.

When you weigh UV LED vs mercury UV curing, the safety gains are clear:

- Mercury-Free: You have no hazardous waste or mercury spill kits to worry about.

- No Ozone: Your indoor air quality stays better for everyone in the room.

- Low Heat: You are much less likely to get a burn from touching the equipment.

- Stable Light: LEDs do not explode or pop like high-pressure mercury bulbs can.

These safety factors help you run a cleaner and more relaxed production line. You spend less time on hazardous material plans and more time on your work. This shift makes your shop a more attractive place for operators and lowers your insurance and compliance burdens.

What Built-In Safety Features Do UV LED Curing Systems Include?

Safety is designed into modern UV LED systems through a mix of mechanical shields and electronic controls. You will find that these systems include interlocks that cut power to the light if a protective door is opened. Plus, the lamp heads are built to point the light only at your product, which keeps stray light away from your eyes.

You should look for these features in your UV LED curing systems:

- Light-Tight Enclosures: Metal boxes that keep the light where it belongs.

- Safety Interlocks: Sensors that stop the light instantly if a shield is moved.

- Software Alarms: Systems that warn you if a fan stops or if the light gets too hot.

- Shielding Curtains: Special fabric or plastic that blocks UV rays at the entry and exit of your machine.

Using high-quality UV LED curing equipment ensures these features work every time. You can trust the gear to protect you even if you make a small mistake. Always check that these sensors are working before you start your shift. A safe machine is your best partner on the shop floor.

What Personal Protective Equipment Is Required for UV LED Curing?

Personal protective equipment is your final line of defense against UV exposure. You must wear UV-rated safety glasses or face shields to protect your eyes from any light that might leak out. Plus, you should wear long sleeves and gloves to keep the light off your skin if you are working near an open curing zone.

Your PPE kit for UV LED curing light work should include:

- UV-Rated Eyewear: Glasses that block 100% of UVA and UVB rays.

- Opaque Gloves: Nitrile or leather gloves that prevent light from hitting your hands.

- Long-Sleeved Shirts: Tight-knit fabric that covers your arms completely.

- Face Shields: Helpful if you are doing maintenance or working with high-power lamps.

You need to make sure your gear is in good condition. Scratched glasses or torn gloves will not give you the protection you need. Wear your PPE every time you are near the machine, even for a short task. Consistency is what keeps your skin and eyes healthy over the long run.

What Are the Best Safety Practices for Operating UV LED Curing Equipment?

Safe operation depends on strict procedures and regular training for every person on your team. You should never look directly at the light, even with your glasses on. Plus, you must inspect your machine shields and interlocks every day to make sure they have not been damaged or bypassed.

When you choose a UV LED curing system, follow these best practices:

- Read the Manual: Know exactly where the risks are for your specific machine.

- Use Warning Signs: Place labels near the light so people know to wear their gear.

- Train Everyone: Ensure even the people walking past the line know not to look at the light.

- No Bypassing: Never tape a sensor or move a shield to see the process better.

- Routine Checks: Test your safety stops once a week to ensure they work.

Following these steps makes safety a habit rather than a chore. You will find that a well-trained team has fewer accidents and less downtime. Your goal is to make sure every operator goes home just as healthy as when they arrived.

How Can UV LED Curing Be Safely Integrated Into Production Lines?

Integration design directly affects your safety by determining how much light can escape into your workspace. You should build your UV LED curing systems into fully enclosed tunnels whenever possible. Plus, using automation like robots or conveyors helps keep your workers away from the light source entirely.

You can improve safety in your UV LED curing applications with these tips:

- Enclosed Tunnels: Build a box over your conveyor belt to trap the light.

- Light Traps: Use baffles or curved paths at the tunnel ends to block reflected light.

- Remote Monitoring: Use cameras to watch the cure so you do not have to stand next to it.

- Automated Off-Switches: Link your light to your conveyor so it only fires when a part is present.

Good integration means you don't have to rely on PPE as your only protection. If the machine is built right, the risk to your operators is nearly zero. Spend the time to design a safe layout at the start, and you will save yourself from many safety headaches later.

Final Thoughts

Safe operation of UV LED curing gear is possible for you when you combine good machine design with the right personal habits. You should trust your safety interlocks but also wear your PPE as a backup. By following your training and keeping your equipment in top shape, you can enjoy all the gains of this technology without putting your health at risk.

Remember that safety is a team effort. Also, keep your workspace clean and your shields in place to ensure a long and secure career in your manufacturing field. By choosing modern UV LED curing equipment, you are already taking the first step toward a cleaner and more secure production future.