Does UV LED Curing Run Cooler Than Mercury UV?

Understanding the thermal profile of your production line is essential for maintaining part quality and worker safety. You will find that heat generation varies significantly between different ultraviolet light sources. This guide examines the temperature behavior of UV LED curing temperature compared to traditional mercury systems and how these differences impact your substrates and facility environment. By evaluating these technical factors, you can better determine which technology aligns with your specific material constraints and goals.

Does UV LED Curing Generally Run Cooler Than Mercury UV Curing?

UV LED curing typically runs at lower operating temperatures compared with mercury UV curing under similar process conditions. You will notice that while both systems generate energy to cure coatings, the heat felt by your parts is much lower with LED technology. This is because LED systems do not emit infrared radiation, which is the primary cause of rising surface temperatures on your shop floor. In a mercury system, a large portion of the electricity is converted into heat rather than usable UV light. When you switch to LED, the energy is concentrated into a narrow ultraviolet band. This results in a cold cure process where your substrates remain much closer to room temperature throughout the production cycle.

Why Do UV LED Curing Systems Tend to Produce Less Heat?

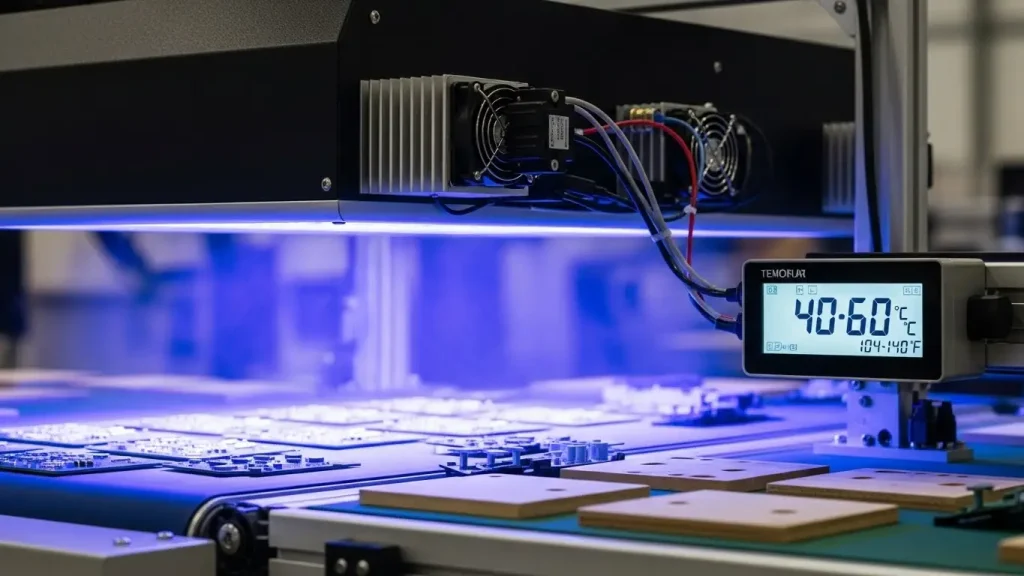

Differences in energy delivery and source design cause UV LED curing systems to produce less heat during operation. Traditional mercury lamps rely on an electrical arc through a gas-filled bulb, a process that creates a broad spectrum of light, including vast amounts of infrared energy. You can think of a mercury bulb as a high-powered heater that happens to emit UV light as a byproduct. UV LEDs are solid-state semiconductors that emit light in a very specific, narrow wavelength. Because they do not rely on a high-temperature arc, they do not produce the infrared wavelengths that naturally heat up your parts. While the LED diodes themselves generate internal heat, this is managed through heat sinks or water chillers at the back of the lamp. This keeps the heat away from your product surface.

How Does Lower Operating Temperature Affect Materials and Parts?

Lower operating temperature in UV LED systems can reduce heat-related stress on materials, particularly when you are working with thin or sensitive substrates. You can process materials like thin-gauge films, heat-sensitive plastics, and delicate electronic components without the risk of warping, melting, or shrinking. This opens up your production capabilities to include products that were previously difficult to cure with traditional lamps. By keeping the part cool, you also maintain better dimensional stability. In industries like high-precision printing or medical device assembly, even a small amount of thermal expansion can lead to alignment errors or bond failures. Using a cooler curing process ensures that your parts stay within their required tolerances from the start of the line to the finish.

Are There Situations Where Mercury UV May Still Run Cooler in Practice?

Under certain conditions, mercury UV systems may appear to run at similar or lower effective surface temperatures if they are equipped with advanced cooling features. You might see this in systems using dichroic reflectors or cold mirrors that are designed to absorb infrared energy before it reaches your part. If your mercury system is heavily shielded and uses high-volume chilled air, the temperature gap between it and an LED system may narrow. Additionally, if you run an LED system at extremely high intensity while moving the parts very slowly, you may still see some heat build-up. Heat in a curing system is not just about the light source; it is also about the total energy dose your part receives. You must always balance your lamp power with your conveyor speed to manage the final temperature of your product.

What Operational Factors Influence Apparent Heat in UV Curing Systems?

Multiple operational factors influence how much heat is felt on parts or around a UV curing system, including dwell time and the distance from the lamp. You will find that the faster your conveyor moves, the less time your parts have to absorb any energy, leading to a lower surface temperature. Conversely, if your parts sit under the light for a long period, they will naturally get warmer. Ambient conditions in your shop also play a role. If your facility is already hot and lacks proper ventilation, your curing equipment will have a harder time staying cool. The distance between the lamp head and the part—often called the working distance—is another major factor. Moving the lamp closer increases the intensity of the UV light but can also trap more heat near the product surface.

How Should Temperature Differences Factor Into Curing System Selection?

Thermal behavior should be one of several considerations when selecting a curing system for your manufacturing facility. You must first evaluate your most heat-sensitive product to see if it can withstand the infrared output of a mercury lamp. If your current scrap rates are high due to thermal distortion, moving to a cooler LED process may provide a better return on investment for your shop. You should also consider the secondary effects of heat. A cooler system reduces the load on your building's air conditioning and can make the workspace more comfortable for your operators. However, you must also ensure that the cooler process still achieves the required chemical bond. Some older ink recipes actually benefit from a small amount of heat to help them flow and level out before they set.

What Are the Key Takeaways on UV LED vs Mercury UV Temperature Behavior?

The core summary of thermal behavior differences is that LED systems provide a targeted, infrared-free cure that protects your materials from heat-related damage. While mercury lamps remain a versatile tool, their high heat output requires significant management and can limit the types of substrates you can process.

- LED systems are cooler because they lack infrared emissions.

- Lower heat protects thin plastics and sensitive electronics from warping.

- Mercury lamps require complex cooling systems to manage high thermal output.

- Your conveyor speed and lamp intensity both affect the final part temperature.

- System selection should be based on your specific material's heat tolerance.

How Do UV LED and Mercury UV Curing Systems Compare Technologically?

To understand why these systems have different heat profiles, you can look at the physical differences in how they generate light. You can find a full technical breakdown on our UV LED vs mercury UV curing page. This explains the spectral output differences that drive the temperature behavior.

What Thermal Limitations Are Common in UV LED Curing?

While LEDs are cooler, they are not completely heat-free. You should be aware of the limitations of UV LED curing when it comes to high-intensity operation. This guide helps you manage expectations for thermal performance in demanding industrial settings.

Should Retrofitting Mercury UV to LED Be Considered for Temperature Reasons?

If your current lamps are melting your parts, it might be time to look at an upgrade. You can learn about the steps for retrofitting mercury UV to LED to help solve your heat-related production issues. This is a common reason for shops to modernize their existing equipment.

What Factors Should You Think About When Comparing LED and UV Curing Lamp Operation?

Managing your shop floor involves more than just picking a lamp. You can find out more about the operational variables in our guides on choosing a UV or LED curing lamp and the differences between light types. These resources help you see how heat affects your daily workflow.

How Does Lower Heat Generation Affect Material Stress?

When you remove infrared energy, you remove the primary cause of thermal expansion in your substrates. This results in less internal stress within the material and a flatter, more consistent final product. Without the need for high-velocity cooling air, you also reduce the risk of dust contamination on your wet coatings.

What Are Common Myths About Heat and UV LED Curing?

A common myth is that UV LED curing produces zero heat. While the beam itself is free of infrared, the part can still warm up slightly as it absorbs the UV energy. Additionally, the LED lamp head produces heat internally that must be managed by fans or water. You must still plan for some thermal management in your system design.

What Are Best Practices to Manage Heat in Any UV Curing System?

Regardless of the technology you use, you should keep your reflectors and lenses clean to ensure maximum efficiency. You should also regularly check your cooling fans and water chillers to prevent the system from overheating. Matching your lamp power to your line speed is the most effective way to keep your part temperatures under control.

Why Does Heat Behavior Matter to Process Outcomes?

Heat affects everything from the flow of your ink to the final bond strength of your adhesive. If a part gets too hot, it may warp and lead to a rejection. If it stays too cool, some older chemistries may not level out smoothly, leading to a textured finish. Understanding the thermal balance of your specific materials is the key to a perfect cure.

Final Thoughts

Finalizing your decision on a curing system requires you to look at heat as a process variable that you can control. While UV LED technology offers a much cooler environment that is safer for many modern materials, it also requires you to be mindful of how your coatings react to a cold cure. By focusing on the thermal needs of your substrates and the efficiency of your equipment, you can build a production line that is both high-performing and reliable. The best system is the one that gives you the results you need without adding unnecessary thermal stress to your parts or your team.