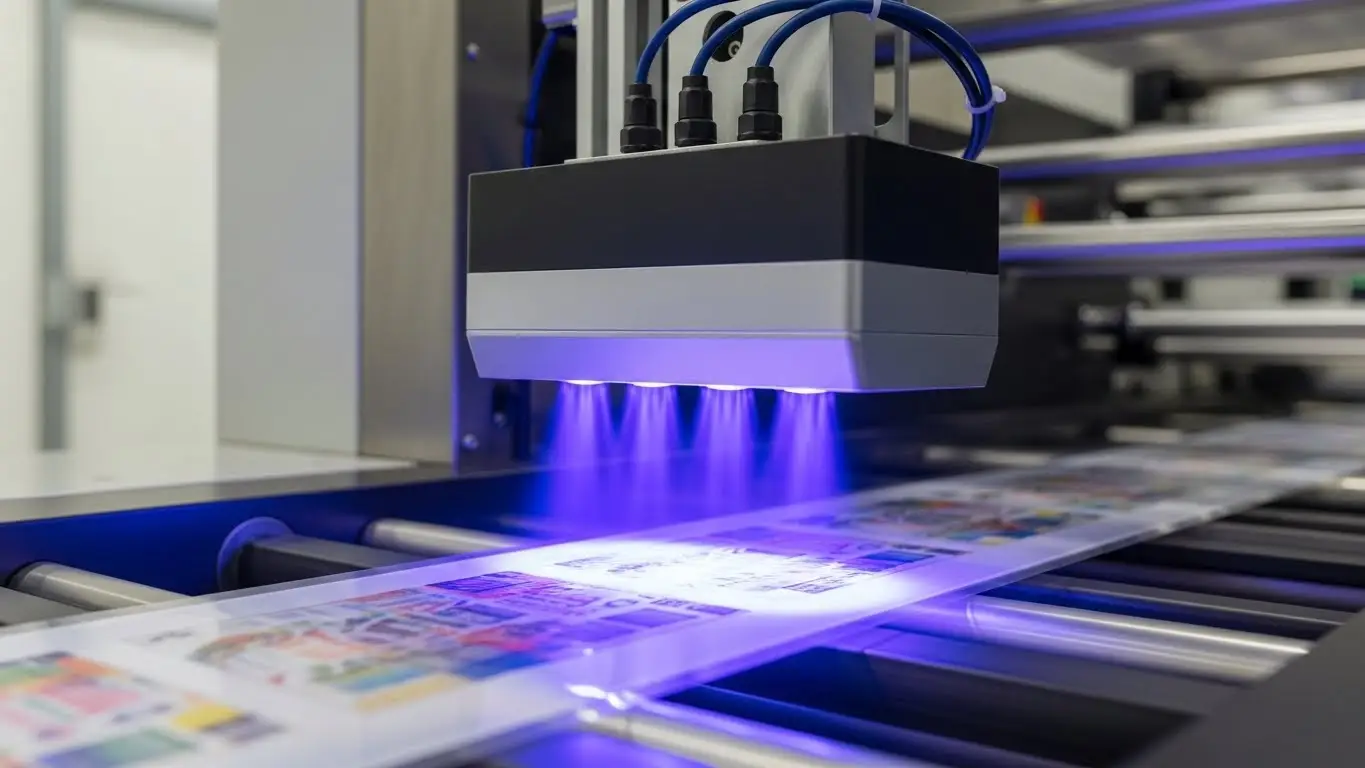

UV LED Curing for Shrink Sleeve Labels: What to Know

UV LED curing for shrink sleeve labels is a process that uses light-emitting diodes (LEDs) to instantly dry inks and coatings without generating the intense infrared heat associated with traditional mercury arc lamps. This "cold cure" technology is critical for shrink sleeves because the substrate materials—such as PETG, PVC, or OPS—are highly heat-sensitive and prone to shrinking or distorting prematurely if exposed to high temperatures during printing. By switching to UV LED, converters can run presses at higher speeds, reduce energy consumption by up to 50-70%, and eliminate the risk of heat-damaged film, ensuring a consistent, high-quality finish for packaging.

Why Heat Management is Critical for Shrink Sleeves

Shrink sleeves are designed to do exactly what their name implies: shrink when exposed to heat. This characteristic makes printing on them a delicate balancing act. If the curing system on a flexographic press emits too much heat, the film can begin to shrink before it is applied to the bottle or container.

Traditional mercury vapor lamps emit a broad spectrum of light, including a significant amount of infrared (IR) energy, which translates directly to heat. This often forces printers to run chill rolls at maximum capacity or slow down the press to prevent the web from distorting.

In contrast, UV LED curing systems emit a narrow band of UV energy (typically 385nm or 395nm) with negligible IR output. This allows for stable web handling even on thin, sensitive films. For a broader look at how this fits into the wider labeling ecosystem, you can read about UV LED Curing for Flexo & Labels.

Key Heat-Related Risks in Traditional Curing:

- Web Distortion: The film stretches or ripples, leading to registration errors.

- Pre-Shrinkage: The label shrinks slightly on the roll, making it unusable for the final application.

- Brittleness: Overheating can affect the structural integrity of the film.

What are the Main Benefits of UV LED for Shrink Sleeves?

Beyond heat management, UV LED technology offers operational advantages that directly impact the bottom line. The most immediate benefit is the "instant-on/instant-off" capability. Unlike arc lamps, which require warm-up time and shutters, LEDs are ready immediately.

Energy Efficiency and ROI

Transitioning to LED drastically lowers energy bills. Because LEDs only consume power when curing (and not during standby or makeready), the savings accumulate quickly. When selecting equipment, looking for the Best UV LED Curing System for Flexo Label Printing often involves finding a balance between peak irradiance and energy efficiency to maximize these savings.

Comparison: UV LED vs. Mercury Arc for Shrink Film

| Feature | UV LED Curing | Mercury Arc (Traditional) |

| Heat Output | Low (Cold Cure) | High (Requires Chill Rolls) |

| Warm-up Time | Instant (0 seconds) | Slow (minutes) |

| Energy Use | Low (saves 50-70%) | High |

| Bulb Lifespan | ~20,000+ hours | ~1,000–2,000 hours |

| Ozone Generation | None | Yes (Requires Extraction) |

Can UV LED curing damage shrink film?

No, UV LED curing is unlikely to damage shrink film because it emits almost no infrared heat.

Because the "action" of the curing happens at a specific wavelength without the thermal blast of IR energy, the film remains cool throughout the process. This capability allows converters to run thinner gauge films, which reduces material costs and waste.

However, success depends on using the correct wavelength. Most standard UV LED applications for labels utilize the 395nm spectrum because it penetrates deep into the ink layers for a solid through-cure. To understand why this specific setting matters for your ink formulation, check out our guide on What Wavelength Is Best for Flexo UV Inks?.

Solving Quality Challenges in High-Speed Printing

One common concern when switching to LED is maintaining cure speed. Shrink sleeves are often printed on high-speed web presses, and the ink must be fully cured instantly to prevent offsetting or smearing.

Overcoming Oxygen Inhibition

In some cases, the surface of the ink may remain tacky due to "oxygen inhibition," where oxygen in the air interferes with the curing reaction. Modern high-power LED systems overcome this by delivering high peak irradiance (measured in Watts/cm²) that drives the reaction faster than oxygen can inhibit it. This is essential for maintaining production rates. If you are facing issues with surface tackiness, learn How to Improve Cure on High-Speed Web Printing.

How do you manage odor in UV LED labels?

Odor is managed by ensuring a complete cure of the ink and using "low migration" LED-specific inks.

For food and beverage packaging—a massive market for shrink sleeves—odor and migration are unacceptable. Odor usually results from unreacted photoinitiators or monomers left in the ink film due to under-curing.

To prevent this, printers must ensure their LED lamps provide sufficient energy density (J/cm²) to fully crosslink the ink polymers. Furthermore, switching to inks formulated specifically for the narrow LED spectrum is vital. For a deeper dive into troubleshooting this common issue, read How to Reduce Odor in UV Flexo Inks with LED Curing.

Frequently Asked Questions

Do I need to change my inks when switching to UV LED?

Yes, generally you must switch to inks formulated for UV LED curing. These inks contain photoinitiators that react specifically to the UV-A spectrum (385-395nm) emitted by the diodes.

Is UV LED curing faster than traditional UV?

It can be. While chemical reaction speeds are similar, the ability to eliminate warm-up times and run the press without worrying about heat buildup often allows the overall production line to run faster.

What is the lifespan of a UV LED lamp?

A high-quality UV LED curing unit typically lasts over 20,000 hours of operation. Since it is only "on" when actually printing, this can translate to many years of service without bulb replacements.

Does UV LED curing produce ozone?

No. Unlike mercury lamps which generate ozone requiring exhaust ventilation, UV LED lamps produce zero ozone, creating a safer work environment and reducing HVAC costs.

Key Takeaways

- Heat Reduction: UV LED is a "cold cure" technology, preventing distortion in heat-sensitive shrink sleeve films (PETG, PVC, OPS).

- Operational Efficiency: Instant on/off capabilities and long lifespan reduce downtime and energy usage significantly.

- Quality Control: Proper wavelength selection (typically 395nm) and high peak irradiance ensure full curing at high speeds.

- Safety & Sustainability: Eliminates ozone generation and mercury disposal hazards while reducing the carbon footprint of the printing process.

Conclusion

Switching to UV LED curing for shrink sleeve labels is no longer just an "option"—it is becoming the standard for converters looking to improve quality and reduce waste. By eliminating the heat risks associated with traditional curing, you protect your delicate substrates and unlock higher production speeds.

Ready to upgrade your label printing process? Evaluate your current press limitations and consider a UV LED retrofit to secure a competitive edge in the shrink sleeve market.