UV LED for UV Ink Curing: Choosing the Right Lamp Head

Finding the perfect uv led for uv ink curing is the single biggest factor in determining your print quality and production speed. Whether you are running high-speed inkjet lines or precision offset printing, the lamp head acts as the heartbeat of your curing system. If that heartbeat is irregular or too weak, your entire production line suffers.

This guide cuts through the technical noise. We will explore exactly how to select a lamp head that matches your ink formulation, speed requirements, and substrate limitations.

What is the Role of the Lamp Head in UV LED Curing?

The lamp head in a UV LED system is responsible for emitting precise UV energy at specific wavelengths to trigger photoinitiators within the ink. This initiates polymerization, instantly transforming liquid ink into a solid polymer. Unlike traditional mercury lamps, an LED head provides monochromatic output, ensuring a "cool cure" without damaging heat-sensitive substrates.

The Shift from Mercury to LED

For decades, the industry relied on mercury arc lamps. They were powerful but inefficient, blasting broad-spectrum light and massive amounts of heat. I recall a project involving thin shrink film where mercury lamps warped the material within minutes. Swapping to a UV LED head solved the heat issue instantly.

Modern LED lamp heads are precision instruments. They don't just "dry" the ink; they cross-link it. However, because LED output is monochromatic (narrow bandwidth), the lamp head must be perfectly matched to the chemistry of your ink. If your lamp emits at 395nm but your ink is formulated for 365nm, the cure will fail, regardless of how much power you throw at it.

Which Wavelength Should I Choose for My Ink Formulation?

For most standard UV ink curing applications, 395nm is the industry standard due to its deep penetration capabilities and high intensity. However, 385nm and 365nm are critical for specific applications like surface curing (reducing tackiness) or clear coats. Always consult your ink manufacturer’s technical data sheet (TDS) before selecting a wavelength.

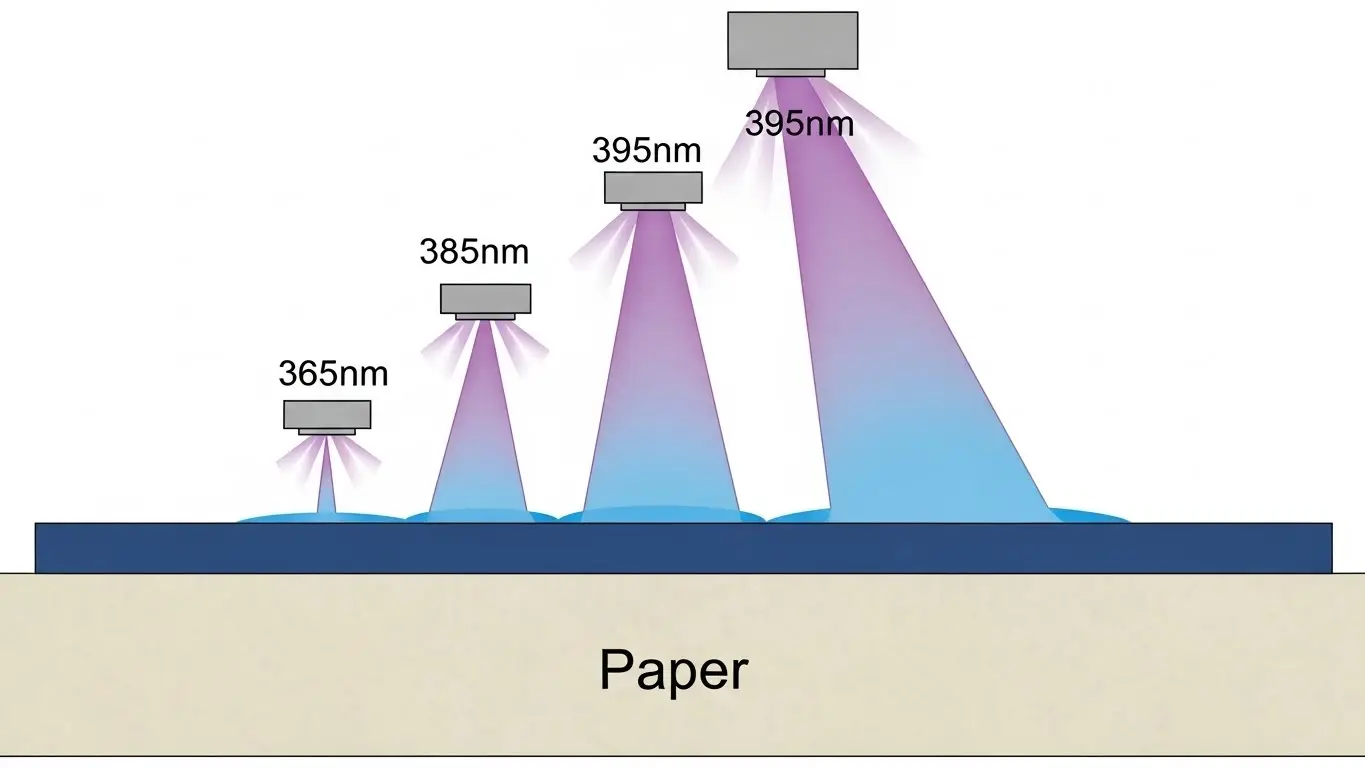

Understanding the Nanometer Spectrum

The wavelength is the "color" of the UV light, measured in nanometers (nm). In the world of UV LED for UV ink curing, we primarily deal with three specific bands.

- 395nm (The Workhorse): This is the most common wavelength for digital inkjet, screen, and offset printing. It offers excellent through-cure (curing the ink layer all the way to the substrate) because longer wavelengths penetrate deeper.

- 385nm (The Middle Ground): This offers a balance between surface cure and through cure. It is often used in more specialized electronic assembly or high-end cosmetic printing where surface finish is paramount.

- 365nm (The Surface Specialist): Shorter wavelengths struggle to penetrate deep, pigmented ink layers, but they are exceptional at curing the very top surface. This is vital for eliminating "oxygen inhibition," which leaves prints feeling sticky or tacky.

Pro Tip: I have seen hybrid systems work wonders. This involves using a 395nm lamp for the main cure and a smaller 365nm "kicker" lamp at the end to seal the surface.

How Do Peak Irradiance and Energy Density Differ?

Peak irradiance (W/cm²) measures the intensity of UV power at a specific point, while energy density (J/cm²) measures the total amount of energy delivered over time. For a successful cure, you need high enough irradiance to penetrate the ink and sufficient energy density (dose) to complete the chemical reaction at your production speed.

The "Punch" vs. The "Soak"

Think of Irradiance as the "punch" and Energy Density as the "soak."

- Irradiance: This is determined by the electrical power of the LED array and the optical efficiency of the lamp head window. High irradiance is necessary to punch through thick, heavily pigmented inks (like white or black).

- Energy Density: This is influenced by the speed of the conveyor. If you run your press faster, the ink spends less time under the light, reducing the energy density.

Real-World Scenario: A client once called me complaining that their black ink was flaking off. Their irradiance was high (16W/cm²), which should have been enough. The problem? They had doubled their line speed. The dose dropped below the threshold needed for polymerization. We didn't need a stronger lamp; we needed to add a second lamp head in series to increase the dwell time (and thus the dose).

If you are unsure how these metrics interact with your specific setup, check out our resource on the UV LED Ink Curing Guide for a deeper dive into the physics of curing.

Should You Choose Air-Cooled or Water-Cooled Lamp Heads?

Choose air-cooled lamp heads for smaller, lower-speed printers where simplicity and low maintenance are prioritized. Choose water-cooled systems for high-power, industrial, or wide-format applications where consistent high-intensity output and compact form factors are required to fit into tight machine architectures.

Air-Cooled Systems

- Pros: No chillers, no hoses, no risk of condensation or leaks. Easier to install.

- Cons: Physically larger (need space for fans/heatsinks), can be noisy, and may circulate dust onto the print surface if not filtered correctly.

Water-Cooled Systems

- Pros: extremely compact profiles, silent operation at the print head, and higher power capabilities. Stable thermal management ensures the LEDs last longer.

- Cons: Requires an external chiller unit and plumbing. You must monitor coolant levels and prevent condensation in humid environments.

When configuring your production line, the cooling method often dictates the physical design of the machine. For a detailed breakdown of installation requirements, review our UV LED Curing System: Setup Considerations.

Why is Optical Uniformity Essential for Print Quality?

Optical uniformity ensures that every millimeter of the print width receives the same amount of UV energy, preventing banding or uncured edges. High-quality lamp heads use specialized optics or reflectors to distribute light evenly, whereas cheaper units often have "hot spots" and "dead zones" that lead to inconsistent adhesion.

The "Stitching" Challenge

In wide-format printing, manufacturers often stitch multiple LED arrays together to cover the full width. If the optics aren't seamless, you get a drop in intensity where the arrays meet. This results in visible lines down the length of the print where the ink is under-cured.

When evaluating a lamp head, ask for the irradiance profile data. You want a flat-top profile, not a Gaussian (bell-shaped) curve. A flat-top profile ensures that the edge of the cure window is just as powerful as the center.

Does the Printing Method Change the Lamp Requirement?

Yes, the printing method dictates the lamp configuration; Inkjet typically requires "pinning" lamps to freeze dots before a final cure, while offset requires high-intensity bars for immediate deep curing. The speed and ink thickness of the process determine whether you need high dose or high peak intensity.

Inkjet vs. Offset Requirements

- Inkjet Printing: The ink is low viscosity. If you don't cure it immediately, the dots spread (dot gain), making the image blurry. Often, small, low-power LED heads are placed right next to the print heads to "pin" the dot in place, followed by a high-power bar for the final cure.

- Offset Printing: The ink is thick and paste-like. The challenge here isn't dot gain, but penetrating the thick layer at breakneck speeds. This demands extremely high peak irradiance.

If you are moving from digital to analog processes, the requirements change drastically. It is worth reading our article, Can UV LED Curing Be Used for Offset Printing?, to understand the specific power demands of offset presses.

What Common Mistakes Occur When Selecting Lamp Heads?

The most common selection mistakes include mismatching wavelengths to ink chemistry, underestimating the cooling requirements, and ignoring the working distance. These errors result in sticky prints, poor adhesion, shortened LED lifespan, and ultimately, rejected products and downtime.

The Working Distance Trap

Light intensity follows the Inverse Square Law—intensity drops off rapidly as you move away from the source.

- 1mm - 5mm distance: Optimization zone for most LEDs.

- 10mm+ distance: Irradiance can drop by 50% or more depending on the optics.

I once diagnosed a system where the customer mounted the lamp head 20mm above the substrate to avoid crashes with warped cardboard. The ink wasn't curing. We switched them to a lamp head with a collimating lens (which focuses the light like a laser beam) rather than a standard flood reflector. This allowed them to maintain the gap without losing intensity.

If you are currently facing quality issues, run through our UV LED Curing Troubleshooting for Inkjet guide before buying new hardware.

What Features Are Non-Negotiable in a UV LED System?

A robust UV LED system must feature variable intensity control (dimming), instant on/off capabilities, and an integrated monitoring system for thermal protection. These features allow operators to adjust for different substrates and speeds while protecting the hardware from overheating failure.

The Specification Checklist

When you are sitting down with a vendor or looking at a spec sheet, look for these specific attributes:

- Field Replaceable Windows: Ink mist will get on the glass. You need to be able to swap the quartz window without disassembling the whole unit.

- Segmented Control: Can you turn off sections of the lamp? If you are printing a 10-inch image on a 20-inch lamp, you save energy and life span by turning off the unused LEDs.

- Interlock Connectivity: The lamp must talk to the printer. If the conveyor stops, the lamp must cut off instantly to prevent burning the substrate.

For a full list of metrics to vet vendors against, use our UV LED Ink Curing System: Spec Checklist for Printing.

| Feature | Standard Reflector | Lens/Focused | Water-Cooled | Air-Cooled |

| Best For | General Flatbed | High Stand-off distance | Industrial/High Power | Entry/Mid-Range |

| Intensity | High (Close range) | High (Long range) | Very High | Moderate |

| Maintenance | Low | Low | Moderate | Low |

| Footprint | Medium | Medium | Small | Large |

Conclusion: Investing in the Right UV LED Technology

Choosing the right uv led for uv ink curing is not just about buying the brightest light. It is about matching the physics of the photon to the chemistry of the ink.

You need to balance wavelength (395nm vs. 365nm), manage the trade-off between irradiance and energy density, and select a form factor that fits your machine. The right lamp head increases production speed, reduces scrap, and lowers energy costs. The wrong one is an expensive paperweight.

Take the time to test. Request a demo unit. Run your specific ink on your specific substrate. If you validate the process before you sign the check, you guarantee a return on investment that pays off for years.