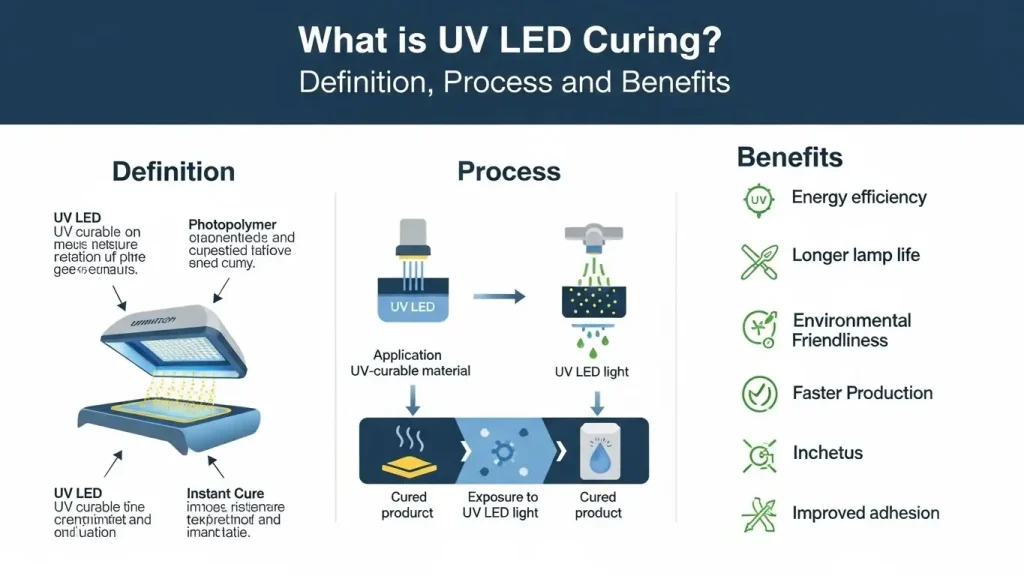

What Is UV LED Curing? Definition, Process, and Benefits

UV LED curing is a process that uses light-emitting diodes to instantly dry or harden inks, coatings, and adhesives on your products. You can find this technology in various industrial settings because it offers a faster and cooler alternative to traditional drying methods. By utilizing specific wavelengths of ultraviolet light, you can achieve a durable finish in seconds while reducing your energy consumption. This guide explains the mechanics of the technology, its primary advantages, and the specific ways you can apply it to your manufacturing operations.

As you look for ways to improve your production speed, understanding UV LED curing technology becomes vital. It represents a move toward more controlled, precise manufacturing. You no longer have to deal with the long wait times of heat-based drying or the hazards of older mercury lamps. Instead, you get a clean, narrow-band light source that reacts only with your specific materials, leaving the rest of your equipment and products unaffected by excess heat.

What Is UV LED Curing?

UV LED curing is a chemical process where ultraviolet light from diodes triggers a reaction that turns liquid materials into solids. You use this method to set inks, resins, and adhesives without relying on heat or evaporation. It creates a nearly instant bond or finish, allowing you to move your items to the next production step without delay.

When you look at your current finishing processes, you might see traditional ovens or mercury lamps taking up space and energy. UV LED curing systems change your approach by using cold-curing technology. Unlike thermal curing, which requires heat to drive out solvents, UV LED uses light energy to reorganize the molecules in your material. This means you do not have to worry about the material shrinking or the substrate warping due to high temperatures.

You can apply this process to a wide range of materials. If you work with thin plastics, labels, or delicate electronic parts, the absence of heat is a major plus. You can achieve a high-gloss or matte finish on your products that is resistant to scratches and chemicals. Because the liquid material is 100% solid once cured, you also reduce the volume of waste in your shop, making your workspace cleaner and your results more predictable.

How Does UV LED Curing Work?

The UV LED curing process works through photopolymerization, where specific light wavelengths hit photoinitiators in your material to start a chain reaction. These photoinitiators absorb the UV energy and force the liquid monomers and oligomers to link together into a solid polymer. This happens almost instantly when your product passes under the light source.

You can view this process as a three-step journey for your material. First, you apply the UV-sensitive liquid to your product. Second, you expose that liquid to the UV LED curing process through a dedicated lamp head. Third, the light triggers the molecules to bond. Because LEDs provide a very narrow band of light, usually around 365nm or 395nm, you get a deep and consistent cure that matches your material's needs exactly.

One of the biggest changes you will notice is the control over the light output. Traditional lamps need to stay on even when no product is present. With UV LED, you have "instant on and off" capability. You can tie the light directly to your conveyor sensor. When a part is detected, the light turns on. When the part passes, the light turns off. This saves you power and prevents the light from shining into your workspace unnecessarily. This level of precision ensures that you only use energy when you are actually creating a finished product.

What Equipment Is Used in UV LED Curing?

The equipment used in UV LED curing includes the LED lamp head, a power controller, a cooling system, and the necessary optics to focus the light. These parts work together to ensure you deliver the correct dose of UV energy to your material. Proper setup of these components ensures your production line runs without frequent maintenance stops.

When you look at your UV LED curing equipment, the lamp head is the most important part. It houses the diodes that produce the light. However, the cooling system is just as important for your long-term success. Diodes generate internal heat that can shorten their life if not managed. You can choose between air-cooled systems, which use fans, or water-cooled systems, which use a chiller. Air cooling is often easier to install, while water cooling allows for a more compact lamp head in tight spaces.

You also need a reliable UV LED curing light controller. This unit manages the electrical current to the diodes. It allows you to adjust the intensity of the light from 1% to 100%. If you change your line speed or switch to a different coating, you can simply adjust the settings on your controller to maintain a perfect cure. This flexibility is what makes the technology so easy to use in different industrial environments.

What Are the Benefits of UV LED Curing?

The benefits of UV LED curing include lower energy costs, faster production speeds, and a safer work environment for you and your team. You also get a longer equipment lifespan, as LEDs last for tens of thousands of hours. Because the process is mercury-free and ozone-free, it is a much greener choice for your factory.

Energy savings are often the first thing you will see in your books. Because the lights are not always on, and because they convert more electricity into usable UV light, you use significantly less power. You also eliminate the need for large exhaust fans because there is no ozone to remove. This reduces your utility bills and simplifies your facility layout.

You also gain the ability to cure at higher speeds. Since the light is so intense and concentrated, you can run your conveyor faster than you could with old-style lamps. Your UV LED curing benefits also include the ability to work with heat-sensitive substrates. You can cure on thin films, heat-shrink labels, and electronics without the risk of melting or damage. This opens up your production to new types of products that you couldn't handle before.

| Advantage | Benefit to You |

| No Mercury | No hazardous waste disposal or spill risks. |

| Low Heat | Safe for thin plastics and heat-sensitive electronics. |

| Instant On/Off | No warm-up time; energy is used only during curing. |

| Long Life | Diodes last 20,000+ hours versus 1,000 for mercury. |

| Compact Size | Easy to fit into existing production lines. |

Where Is UV LED Curing Commonly Used?

You will find UV LED curing used in industries like commercial printing, electronics manufacturing, medical device assembly, and industrial coatings. Its ability to provide a fast, cool cure makes it ideal for high-precision tasks. You can use it anywhere a durable bond or protective finish is required on a mass scale.

Printing and Packaging

In your printing shop, you can use UV LED curing applications to set inks on labels and flexible packaging. Since the ink dries instantly, you can stack or roll your products right away. This prevents smearing and allows you to run your presses at their maximum speed. You also get better color consistency because the ink doesn't have time to soak into the material.

Electronics Manufacturing

When you build circuit boards, you need to protect them with conformal coatings. UV LED allows you to cure these coatings in seconds without heating up the sensitive chips. You can also use it to bond small components or seal sensors. The precision of the light ensures that only the intended area is cured, which is vital for complex electronic assemblies.

Medical Device Production

If you manufacture medical tools like syringes or hearing aids, you need a bond that is both strong and safe. UV LED systems provide a consistent cure that meets strict health standards. Since the systems stay cool, they are perfect for assembly in cleanrooms where temperature control is critical.

Automotive and Industrial Coatings

You can apply UV-curable finishes to automotive trim, headlights, and interior parts. These coatings provide a hard, scratch-resistant surface that stands up to heavy use. By using LEDs, you can finish these parts faster and with a much lower rejection rate compared to thermal drying.

How Does UV LED Curing Compare to Mercury UV Curing?

UV LED curing differs from mercury UV curing by providing a narrow band of light rather than a broad spectrum. Mercury lamps produce heat and ozone, which you must manage with cooling and exhaust systems. LEDs are more focused, stay cooler, and do not contain toxic mercury, making them a more sustainable choice for your shop.

When you look at UV LED vs mercury UV curing, the maintenance costs are a big factor. Mercury bulbs need to be replaced every 1,000 to 2,000 hours. They also lose their strength over time, which can lead to uncured spots on your products. LEDs maintain a steady light output for up to 30,000 hours. This means you have fewer shutdowns for repairs and more consistent quality on every shift.

Another difference is the start-up time. A mercury lamp can take 15 to 20 minutes to reach full power. If you have a power glitch, your whole line stops while you wait for the bulbs to cool down and restart. Your LED system is ready the moment you turn it on. This keeps your production moving and reduces the frustration of unexpected downtime in your facility.

What Safety Considerations Apply to UV LED Curing?

Safety in UV LED curing involves protecting your eyes and skin from direct exposure to the light. While these systems do not produce harmful ozone or contain mercury, the concentrated UV energy can still cause burns or eye damage. You must use proper shielding and personal protective equipment (PPE) whenever the system is running.

You should always ensure that your equipment has light shields to keep the UV energy contained. If your workers need to be near the curing area, they should wear UV-rated safety glasses and gloves. Because the system is mercury-free, you do not have to worry about the dangerous cleanup associated with a broken bulb. This makes your UV LED curing safety plan much easier to manage.

You also benefit from the lack of heat. You won't have hot surfaces that can cause accidental burns to your operators. However, you should still follow all lockout-tagout procedures when maintaining the equipment. Keeping the light optics clean and checking the cooling fans or chillers will ensure the system stays safe and performs at its best for years.

How Do You Choose the Right UV LED Curing Solution?

To choose the right UV LED curing system, you need to match the wavelength of the light to the requirements of your ink or adhesive. You also must consider your line speed, the distance from the lamp to the product, and your cooling preferences. Talking to your material supplier is the best way to start this process.

Start by checking the datasheet for your coatings. It will tell you the peak wavelength needed for a full cure. Most industrial materials are formulated for 365nm, 385nm, or 395nm. If you choose a lamp with the wrong wavelength, your product will stay sticky or fail to bond. You should also look at the intensity (irradiance) of the lamp. A faster production line needs a more powerful light to cure the material in the short time it passes under the lamp.

Think about how the system will fit into your factory. If you have limited space, you might prefer a water-cooled system because the lamp heads are smaller. If you want a simpler installation, an air-cooled system might be better. By looking at your total cost of ownership—including power use and maintenance—you can find a solution that helps your business grow without adding unnecessary complexity to your shop.

Final Thoughts

UV LED curing is becoming the standard for modern industrial finishing for good reason. It gives you a way to improve your speed and quality while lowering your impact on the environment. By moving away from heat and mercury, you create a more efficient and safer workplace that is ready for the demands of high-speed manufacturing.

As you evaluate your next steps, consider the materials you use and the bottlenecks in your current production. A switch to LED technology could be the change you need to reduce your costs and increase your output. With the right wavelength and a well-matched system, you can achieve a perfect cure every time, ensuring your products are ready for your customers as soon as they leave the line.

Frequently Asked Questions About UV LED Curing

What is the main difference between UV LED and mercury curing?

The main difference is the light spectrum and heat. Mercury lamps emit a wide range of light and a lot of heat, which can damage thin materials. UV LED systems emit a narrow band of light and very little heat, making them safer for delicate products and much more energy-efficient for your shop.

Does UV LED curing produce ozone?

No, UV LED systems do not produce ozone. Traditional mercury lamps create ozone when their light reacts with oxygen in the air, requiring you to install expensive exhaust systems. With LEDs, you can skip the ventilation for ozone and enjoy a cleaner, safer breathing environment for your team.

Can I use my old inks with a new UV LED system?

You likely need to switch to LED-compatible inks or adhesives. Traditional materials are often designed to react with the broad spectrum of a mercury lamp. LED-curable materials are specifically made to react with the narrow wavelength of the diodes. Most suppliers now offer a wide range of these products.

How long does a UV LED lamp head last?

You can expect a high-quality UV LED lamp head to last between 20,000 and 30,000 hours. This is about 20 times longer than a standard mercury bulb. This longevity means you will spend less time on repairs and more time on production, leading to a much better return on your investment.

Is UV LED curing safe for all plastics?

Yes, it is safer for plastics than almost any other method. Because the light is "cold," it does not cause the heat-related warping or melting that you often see with thermal ovens or mercury lamps. This allows you to use thinner and cheaper plastic films without losing quality.

How do I know if my product is fully cured?

You can check for a full cure by testing the surface hardness or using a cross-hatch adhesion test. A fully cured product will not feel sticky and the coating will not peel off when scratched. Following the recommended light intensity and line speed for your specific material will ensure a perfect result every time.