Top Benefits of UV LED Curing for Production Lines

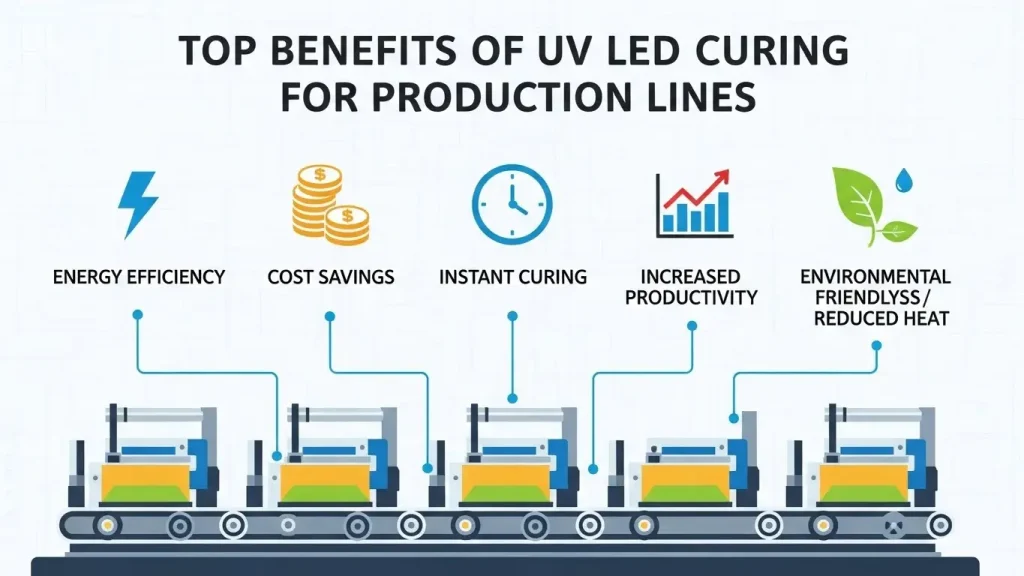

What are the benefits of uv led curing for your manufacturing facility, and how do they change your bottom line? You will find that this technology offers faster speeds, lower power costs, and a much safer workspace for your team. By moving away from traditional heat-based drying, you gain precise control over your finish and reduce your waste. This guide explains the key advantages of using light-emitting diodes to cure your products and why this shift is vital for modern production lines.

As you look to improve your facility, understanding UV LED curing technology is your first step. You get a tool that reacts instantly and stays cool, which protects your products and your equipment. You can expect a deep look into the specific gains you will see in speed, maintenance, and material safety as you integrate these systems into your workflow.

What Is UV LED Curing?

UV LED curing is a cold-curing process that uses ultraviolet light from diodes to harden inks, adhesives, and coatings instantly. You apply specific light wavelengths to trigger a chemical reaction called polymerization, which transforms liquid materials into tough solids without relying on heat or evaporation.

When you look at your current production, you likely see a need for speed and consistency. UV LED curing systems meet this need by focusing energy only on the coating. You do not have to wait for solvents to leave the material or for the product to cool down in a long tunnel. This makes your entire process more compact and much faster than older methods.

What Are the Benefits of UV LED Curing for Production Speeds?

The benefits for your production speed include instant on-and-off capability and much faster cure times compared to traditional drying. You eliminate the 20-minute warm-up periods required by mercury lamps, which means your line is ready to run the moment you start your shift. This lead to a higher total throughput for your shop.

You save a lot of time every day because your UV LED curing light is always ready. If your conveyor stops for a brief check, the light turns off immediately. When you are ready to start again, the light hits full power at the push of a button. You no longer have to worry about your product sitting under a hot lamp during a line pause, which prevents damage and waste.

Since the chemical reaction happens in less than a second, you can increase your belt speed. Your inks and glues set so fast that you can move parts to the next station or pack them right away. This removes the bottleneck of drying and lets you handle more orders in the same amount of time. You get a smoother workflow that keeps your production moving without any unnecessary delays.

How Does UV LED Curing Improve Energy Efficiency?

UV LED curing improves your energy efficiency by consuming up to 70% less power than traditional mercury systems. You only use electricity when the light is active, and the diodes convert a much higher percentage of that power into usable UV light. This lowers your utility bills and reduces the load on your factory’s electrical system.

When you look at your UV LED curing equipment, you see a system built for savings. Traditional lamps waste a lot of energy creating infrared light, which is just heat you do not need. LEDs produce a narrow band of light that is perfectly matched to your material. You spend your money on the cure itself, not on heating up your work area or running massive cooling fans to handle excess heat.

You also save on your facility costs. Since the process is cool, you do not have to run your air conditioning as hard to keep your shop floor comfortable. You also remove the need for large exhaust systems to pump out ozone or hot air. These small changes add up to big savings every month, helping you run a more profitable and sustainable production line.

Why Is Lower Maintenance a Key Benefit for Production Lines?

Lower maintenance is a key benefit because UV LED lamp heads last for 20,000 to 30,000 hours, which is about 20 times longer than mercury bulbs. You get more uptime for your production line because you are not constantly stopping to replace burnt-out bulbs. This leads to a more predictable schedule and lower labor costs for your team.

You avoid the frustration of a fading bulb. Traditional lamps lose their power slowly, which can cause your parts to be under-cured without you noticing. Your UV LED curing systems stay at a steady intensity for years. You do not have to spend time cleaning reflectors or checking for the signs of a dying lamp. Your line stays active, and your results stay consistent from the first part of the day to the last.

Think about the time your team spends on repairs. With LEDs, you remove the risk of glass breakage and the need to handle hazardous mercury. Your maintenance check becomes a simple look at the cooling fans or the water lines. This simplicity keeps your shop running and ensures that your equipment is always ready to work when you have a big order to fill.

How Does Better Process Control Benefit Your Quality?

Better process control benefits your quality by providing a stable light output and a narrow wavelength that matches your material exactly. You get a consistent cure every time, which reduces your rejection rate and prevents customer complaints. This precision allows you to meet strict standards for bonds and finishes in high-tech industries.

Using UV LED curing technology gives you a digital way to manage your line. You can dim the lights or pulse them to match your speed perfectly. If you change your product, you can simply adjust the settings on your controller to get the right dose of light. You do not have to guess if your parts are cured; you can see the results in the steady, even finish of every piece that leaves the belt.

This level of control also helps you with complex shapes. You can set up your lamp heads to hit your product from different angles, ensuring that no part stays wet. Because the light does not flicker or dim over time, you can trust your process to deliver the same high quality every day. This reliability is vital for building a brand that your customers can trust for high-performance parts.

Why Is Lower Heat Generation Important for Your Materials?

Lower heat generation is important because it allows you to cure coatings on heat-sensitive materials like thin plastics and films without melting them. You can use lighter and cheaper substrates that would warp or burn under traditional lamps. This expands your product range and lets you offer more options to your customers.

When you use your UV LED curing light, the energy stays focused on the surface. You do not heat up the part itself. This is a huge gain for electronics where high heat could damage sensitive chips. It is also great for medical gear made of thin plastic. You get a tough, hard finish while keeping the part at room temperature.

You also see less distortion in your finished products. In the past, heat could make paper labels curl or cause plastic parts to shift out of shape. Since the LED process stays cool, your products stay flat and true to their original dimensions. You get a better-looking product that fits into its packaging perfectly every time. This helps you maintain a high standard for every item you produce.

What Are the Environmental and Safety Advantages for Your Team?

The environmental and safety advantages include a mercury-free workspace and the removal of harmful ozone gas from your air. You do not have to worry about the dangerous cleanup of a broken bulb or the high costs of hazardous waste disposal. This creates a much healthier and more pleasant environment for your workers.

Your UV LED curing safety plan becomes much simpler. You do not need to install massive ventilation systems to pump out the ozone that mercury lamps create. You also remove the risk of high-heat burns to your operators. While you still need to protect eyes and skin from the UV light itself, the overall risks in your shop are much lower than they were with old technology.

By choosing this path, you also meet your green goals. You use less power, produce less waste, and remove toxic materials from your facility. This is good for your reputation and helps you stay ahead of environmental rules. Your team will appreciate the cleaner air and the safer gear, and your business will benefit from being a responsible, modern manufacturer.

How Do You Choose the Right UV LED Curing System?

To choose a UV LED curing system, you must match the wavelength of the light to the chemistry of your ink or adhesive. You also need to look at your line speed and the distance between the light and your product. Getting these factors right ensures you see all the benefits of the technology in your daily work.

| Factor | What to Check | Why it Matters |

| Wavelength | 365nm, 385nm, 395nm | Must match your ink's specific recipe. |

| Line Speed | Feet per minute | Faster lines need more light intensity. |

| Working Distance | Gap from lamp to part | Light loses power as the gap grows. |

| Cooling | Air or Water | Needs to fit your shop’s utilities. |

Think about your long-term plans. If you plan to grow your production, look for a system that can be scaled or adjusted. Talk to your material supplier to see which wavelengths they recommend for the best cure. By planning your setup carefully, you can build a production line that is fast, safe, and ready for any task your customers bring to you.

Final Thoughts

UV LED curing offers a clear path to a more efficient and profitable production line. By moving to this tech, you gain speed, save on power, and protect your team from heat and toxins. It is a proven way to improve your quality while lowering the costs of maintenance and waste.

As you evaluate your current setup, think about the bottlenecks in your drying process. A switch to LED technology can remove those delays and give you the edge you need to stay ahead. With the right system in place, your production will be faster, cleaner, and much more reliable for the years ahead.